Reinforcing structure and sealing method for perforated cylindrical composite pressure-resistant shell

A technology of composite materials and pressure-resistant shells, which is applied in the field of fiber composite materials, can solve problems such as structural reinforcement problems at openings, structural damage, and reduced mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the description of the present invention, some terms used to describe the orientation and position include "arc", "cylindrical segment", "inner", "outer", "end face", "coaxial", etc. These terms are only for convenience The invention is described without indicating or implying that the structures referred to must operate in a particular orientation and therefore should not be considered limiting of the invention. This embodiment provides a clear and complete description of the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings. It should be noted that what is described is only one embodiment of the present invention, but not all embodiments. Therefore, it should not be regarded as a limitation of the present invention.

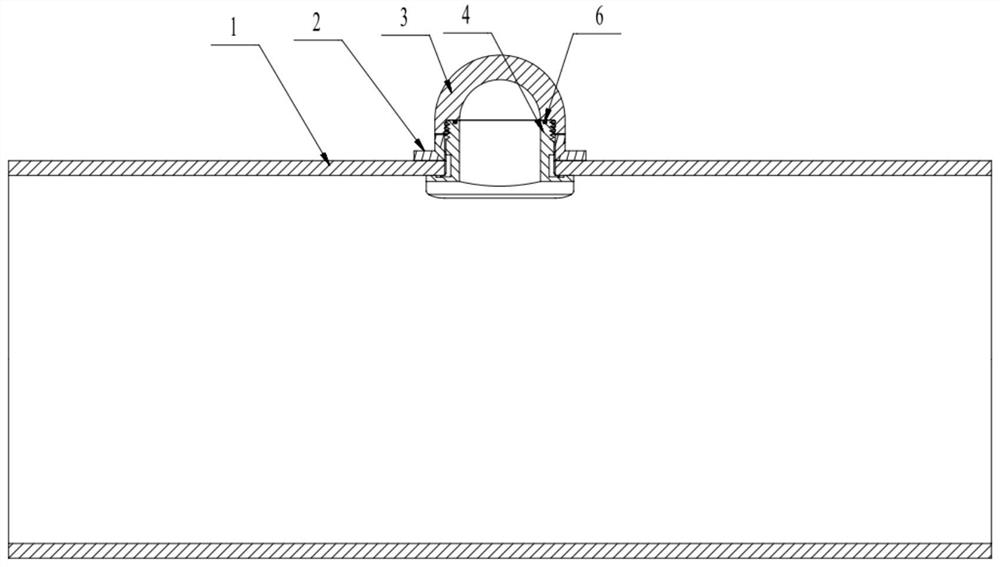

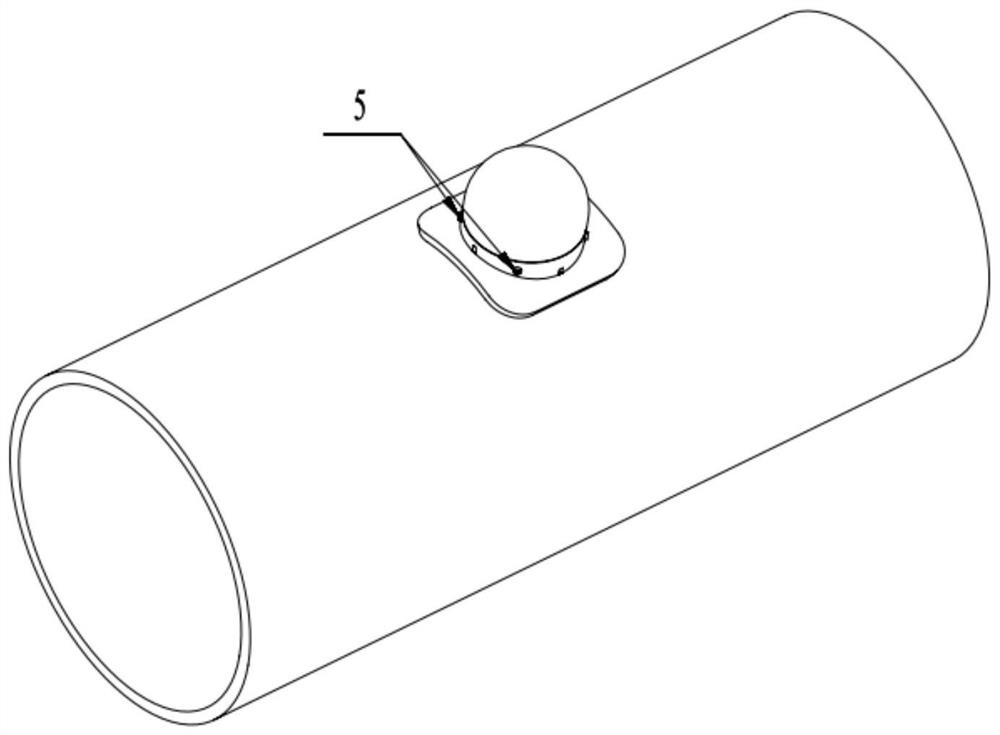

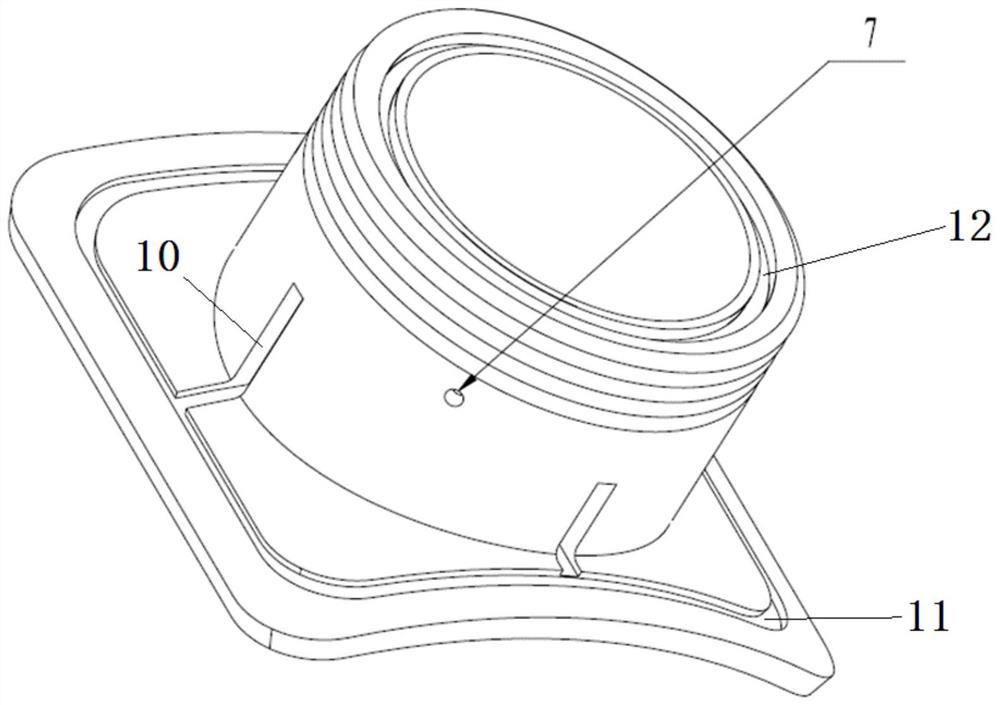

[0033] see Figure 1-Figure 5 , an opening reinforcement and sealing structure and method for a composite material cylindrical pressure-resistant shell, including a shell, a reinforcement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com