Paper straw production equipment facilitating material replacement

A technology for production equipment and straws, which is applied in the field of paper straw production equipment that is convenient for refueling, can solve the problems that the paper straw processing process cannot be carried out continuously, increases the work intensity of equipment operators, and lacks a convenient refueling mechanism, etc., and achieves improvement. Improve material efficiency, prevent solidification, and improve the effect of the splicing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

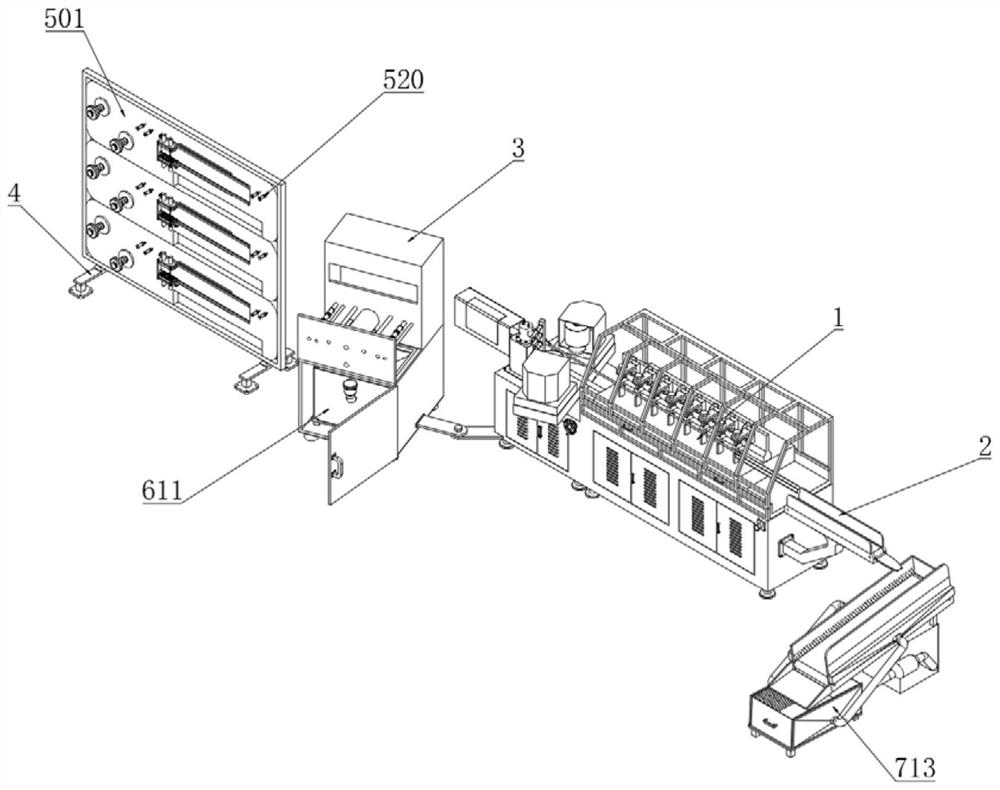

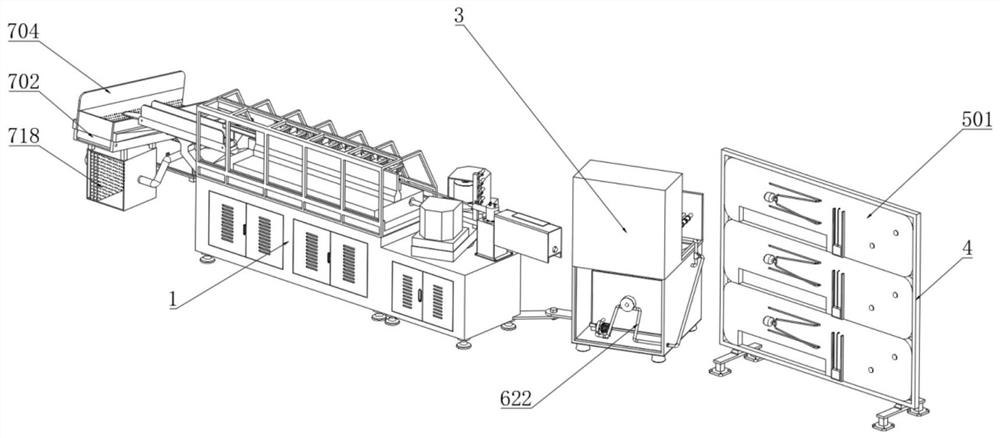

[0031] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a paper straw production equipment that is convenient for refueling, including a paper reel main body 1, a transfer conveyor belt 2 is fixedly installed at one end of the paper reel main body 1, and the other end of the paper reel main body 1 A brushing rack 3 is provided, and a loading rack 4 is arranged on one side of the brushing rack 3;

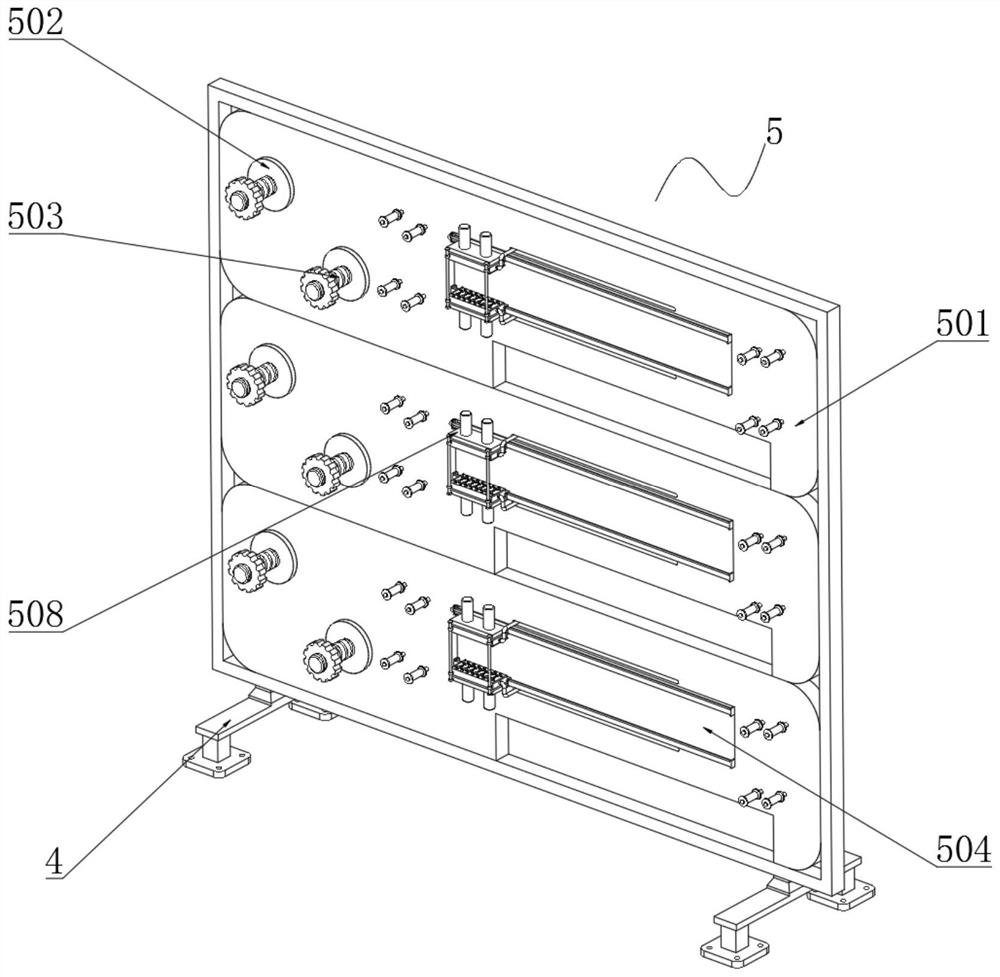

[0032] The inner side of the feeding rack 4 is provided with a convenient paper roll refueling mechanism 5, which is used to quickly install and replace the paper roll, and quickly splice two paper rolls;

[0033] The convenient paper roll refueling mechanism 5 includes a mounting horizontal plate 501, a main mounting frame 502, a secondary mounting frame 503, a fixed horizontal plate 504, a T-shaped guide rod 505, a limit plate 506, a sliding ferrule 507, a mounting slide plate 508, a hydraulic Telescopic rod 509, installation air box 510,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com