All-weather brewing method for Luzhou-flavor liquor

A strong-flavor liquor and aging technology, applied in the field of winemaking, can solve the problems of volatile alcohol, increased labor intensity of workers, and easy corruption of yellow water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

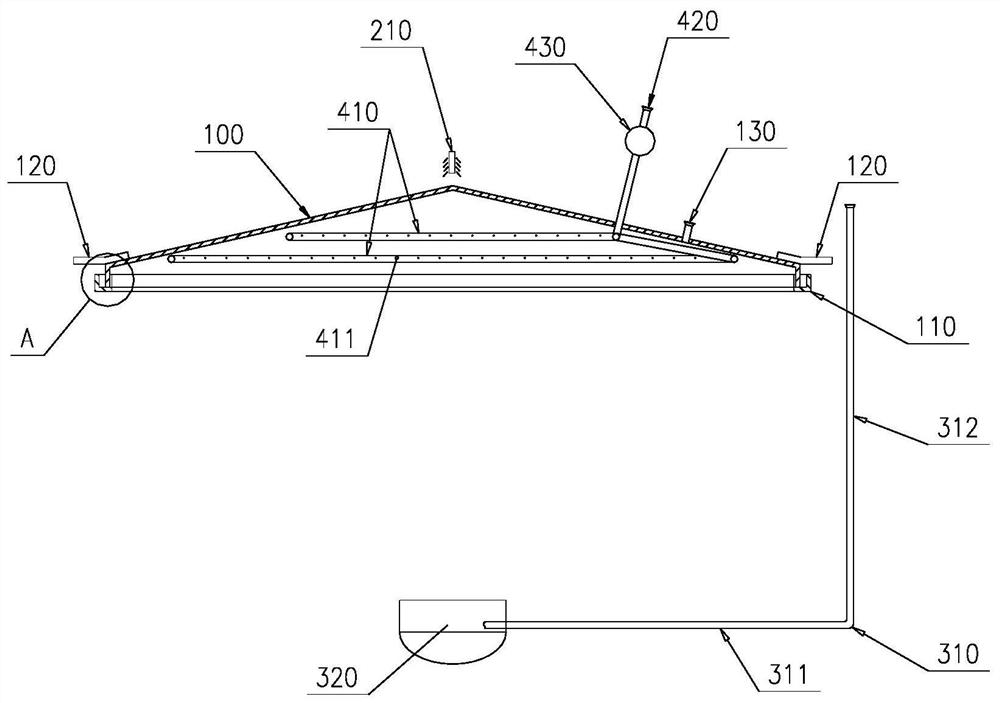

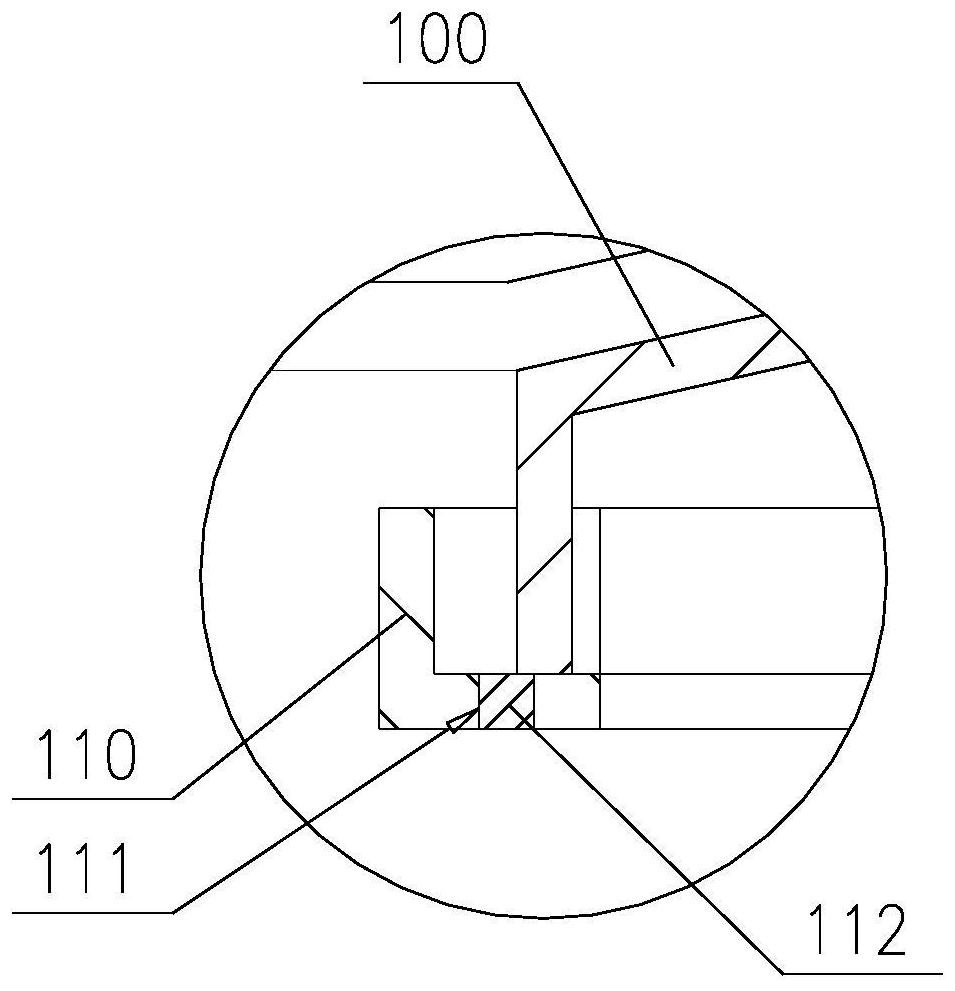

[0069] This embodiment adopts as Figure 4 Stainless steel cellar shown for winemaking:

[0070] The total fermentation time of the distiller's grains in the cellar is 45 days;

[0071] After fermentation to about 28 days, yellow water is produced in the cellar, and the yellow water gradually seeps naturally in the yellow water collection tank 320 at the bottom of the cellar, at this time, the yellow water is extracted from the collection tank, and the extracted yellow water is sealed and placed for later use ;

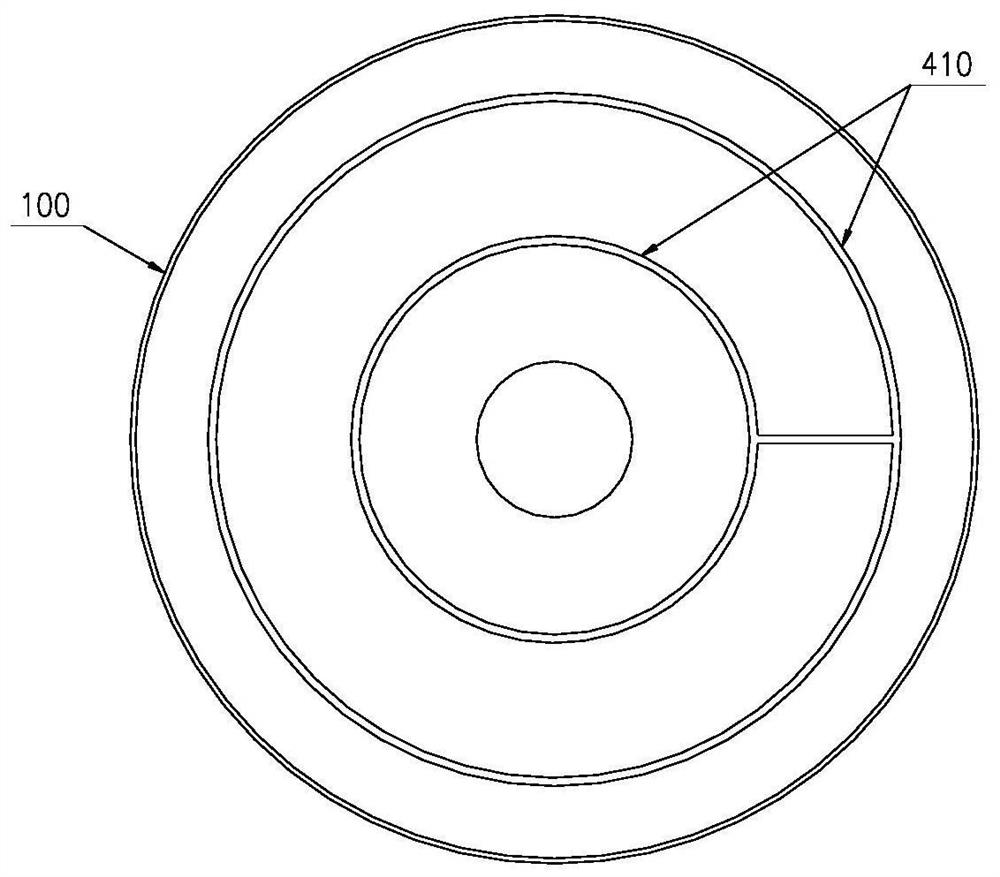

[0072] When the cellar is fermented for 40 days, the spare yellow water is heated to 30-35°C, and the yellow water is sprayed and injected from the top of the cellar by using the yellow water spray injection device 410, so that the yellow water can be used to spray the dried distiller's grains in the middle and upper parts of the cellar. Soaking, keeping the humidity of distiller's grains at 60% to 64%, turning into distiller's grains containing water;

[0073] Wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com