Reaming device for geological exploration sampling

A technology for geological exploration and soil borrowing sleeves, which is applied in the directions of support devices, drilling equipment and methods, drilling equipment, etc., can solve the problems of affecting the effect of hole reaming, the difference in the falling speed of the drill bit affecting the reaming efficiency, and the falling of soil, etc. The effect of increasing the drilling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

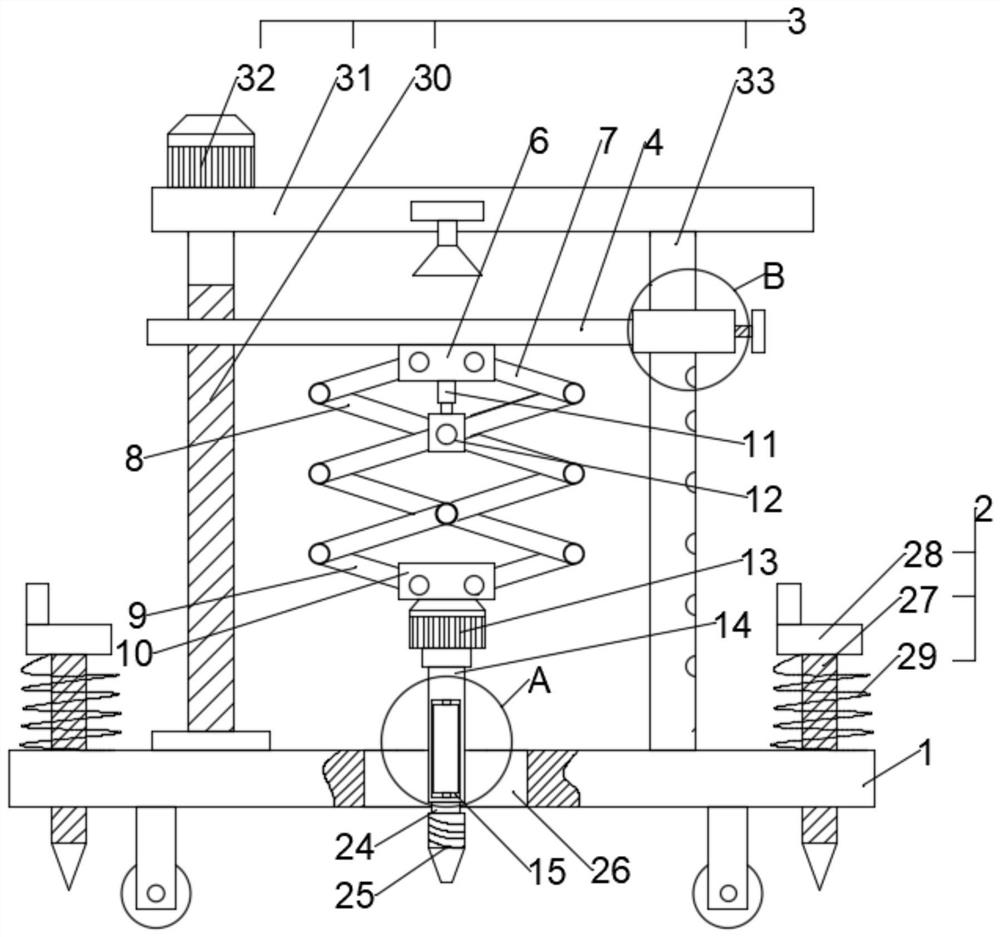

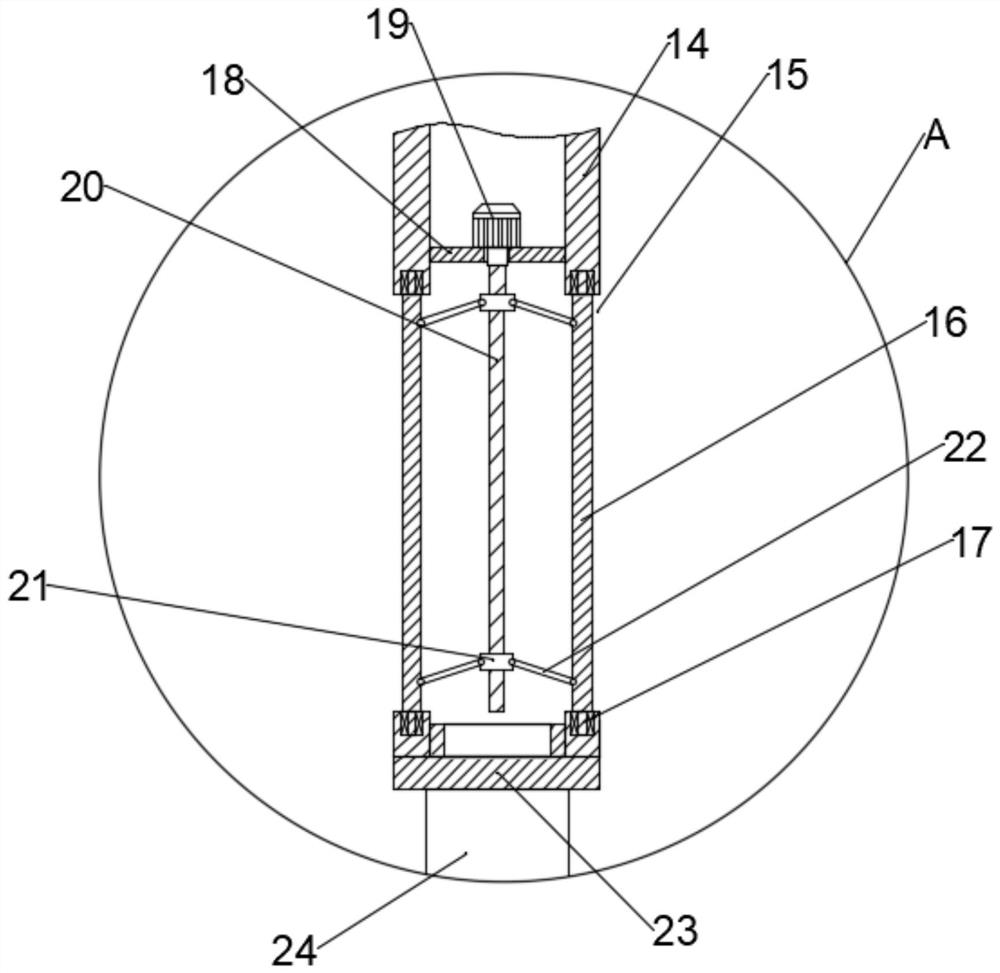

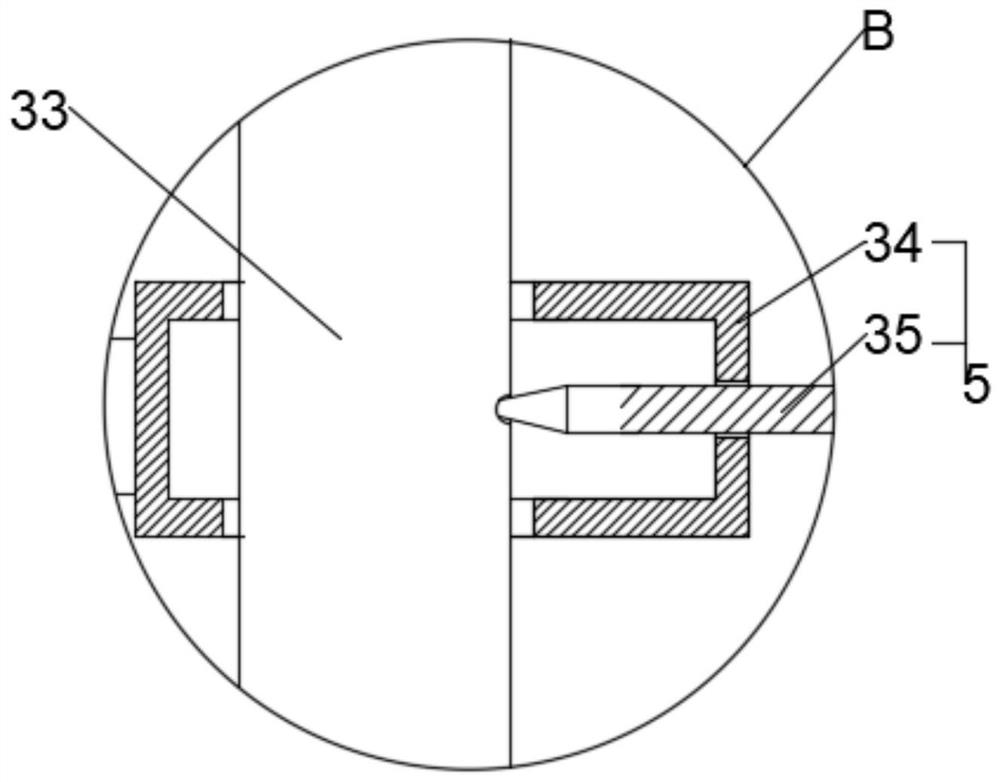

[0026] see Figure 1~6 , in an embodiment of the present invention, a geological prospecting sampling hole reaming device includes a base 1, a fixing mechanism 2 and a lifting mechanism 3, the fixing mechanism 2 and the lifting mechanism 3 are fixedly connected to the base 1, and the lifting mechanism 2 A lifting plate 4 is connected to the upper side of the lifting plate 4 and a positioning mechanism 5 is connected to one side of the lifting plate 4. The lower end surface of the lifting plate 4 is fixedly connected with a first U-shaped seat 6, and two relative rotations are connected in the first U-shaped seat 6. First connecting rod 7, two first connecting rods 7 lower ends are respectively connected with a articulated rod 8, and described articulated rod 8 has several, and every two articulated rods 8 are a group and the two articulated rods 8 of every group are equal to each other. Cross-symmetric hinged, the two lower ends of each set of hinged rods 8 are hinged with the...

Embodiment 2

[0036] The difference between this embodiment of the present invention and Embodiment 1 is that the fixing mechanism 2 includes a positioning rod 27, a rotating seat 28 and a spring 29, and four positioning rods 27 are arranged in a rectangular shape on the base 1 and the four positioning rods 27 All are threadedly connected with the base 1, the upper end of each positioning rod 27 is fixedly connected with a rotating seat 28 and each rotating seat 28 is connected with the base 1 by a spring 29, and the lower end of each positioning rod 27 is tapered;

[0037] The working principle of this embodiment: respectively rotate the rotating seat 28 at the upper end of the four positioning rods 27 to drive the fixedly connected positioning rods 27 and the base 1 to be threaded, so the positioning rods 27 move downward and insert the base 1 with the base 1 through the tapered end. The ground is fixed firmly, and the spring 29 connected between each rotating seat 28 and the base 1 can in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com