A Mechanics Analysis Method for Bottom Hole Assembly with Angle

A bottom hole assembly and analysis method technology, applied in the direction of instrumentation, geometric CAD, design optimization/simulation, etc., can solve problems such as inaccurate calculations, achieve the effects of reducing drilling costs and increasing drilling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

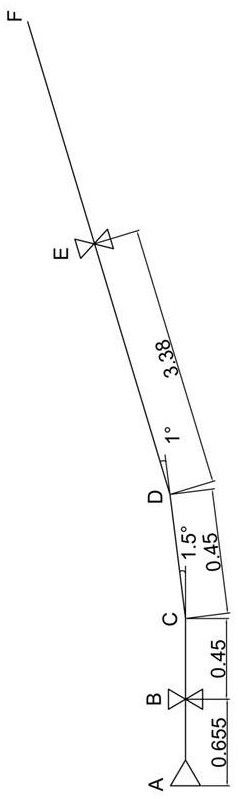

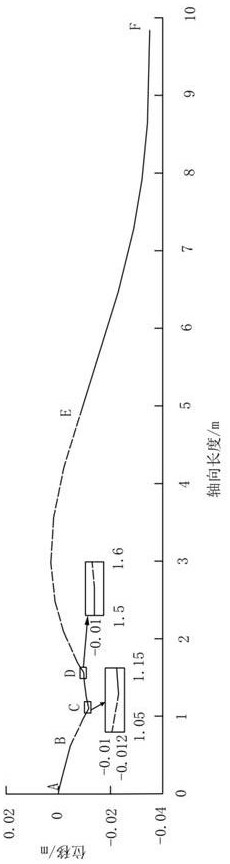

[0067] combined with Figure 1-8 The present invention is further described:

[0068] A method for mechanical analysis of a bottom hole assembly with an angle, comprising the following steps:

[0069] 1. Simplify the BHA with curved corners:

[0070] The following assumptions are made for BHAs with bends: the deformation between BHAs with bends is small elastic deformation; the weight on bit acts on the center of the drill bit, and the center of the drill bit is located on the borehole axis; It is a rigid body, the diameter of the borehole is the outer diameter of the drill bit and there is no change in borehole size; the point contact between the stabilizer and the well wall.

[0071] 2. Body mechanics analysis of bottom hole assembly with curved angle:

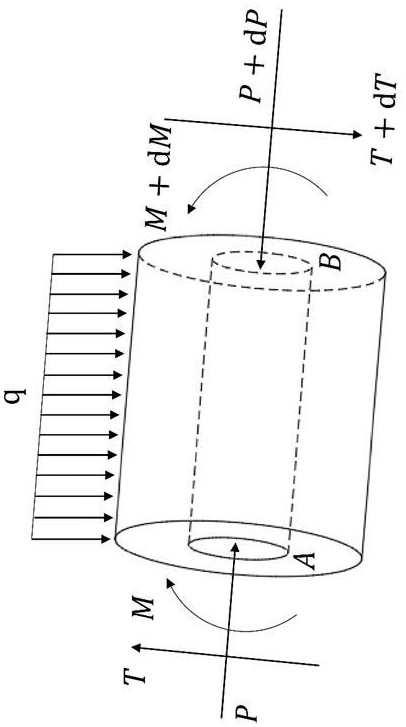

[0072] Take a micro-element with length dx at any position of the bottom hole assembly beam column with a bend, and establish a coordinate system with the center of the A section as the zero point. The force analysis is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com