Mechanical analysis method for bottom drilling tool assembly with bend

A bottom hole assembly and analysis method technology, applied in the direction of instruments, electrical digital data processing, geometric CAD, etc., can solve problems such as inaccurate calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

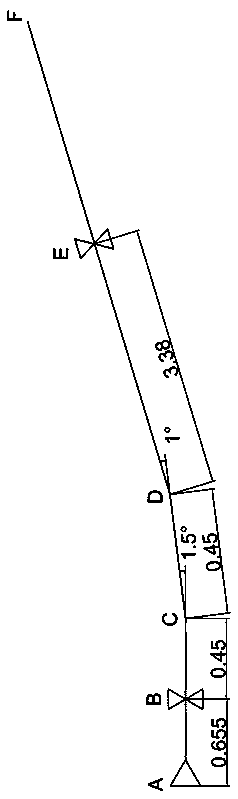

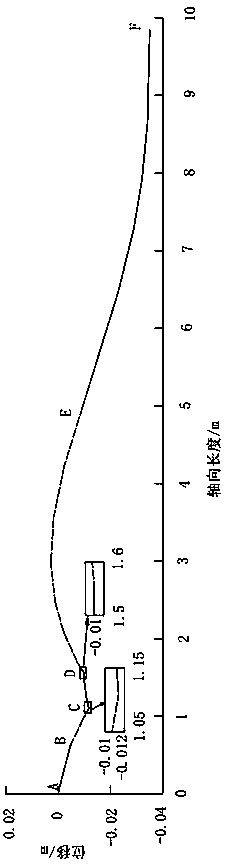

[0069] combined with Figure 1-8 The present invention is further described:

[0070] A method for mechanical analysis of a bottom hole assembly with an angle, comprising the following steps:

[0071] 1. Simplify the BHA with curved corners:

[0072] The following assumptions are made for BHAs with bends: the variation between BHAs with bends

[0073] The shape is a small elastic deformation; the weight on bit acts on the center of the drill bit, and the center of the drill bit is located on the axis of the borehole; the well wall is regarded as rigid

[0074] The diameter of the wellbore is the outer diameter of the drill bit and there is no change in the size of the wellbore; the point contact between the stabilizer and the well wall.

[0075] 2. Body mechanics analysis of bottom hole assembly with curved angle:

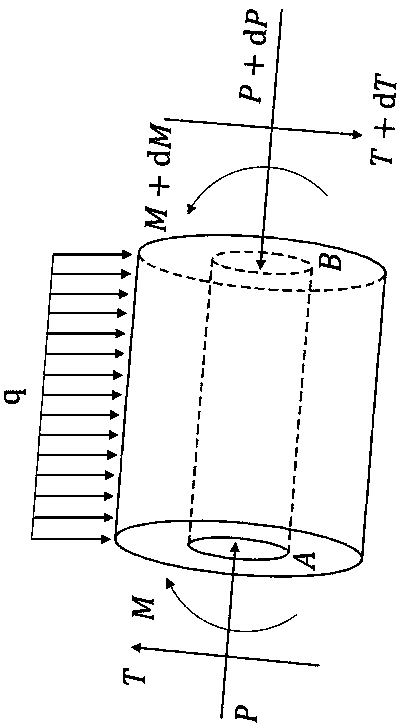

[0076] Take a micro-element with length dx at any position of the bottom hole assembly beam column with a bend, and establish a coordinate system with the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com