Flap valve magnetic closing performance test equipment and test method

A test equipment, flap valve technology, used in mechanical valve testing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

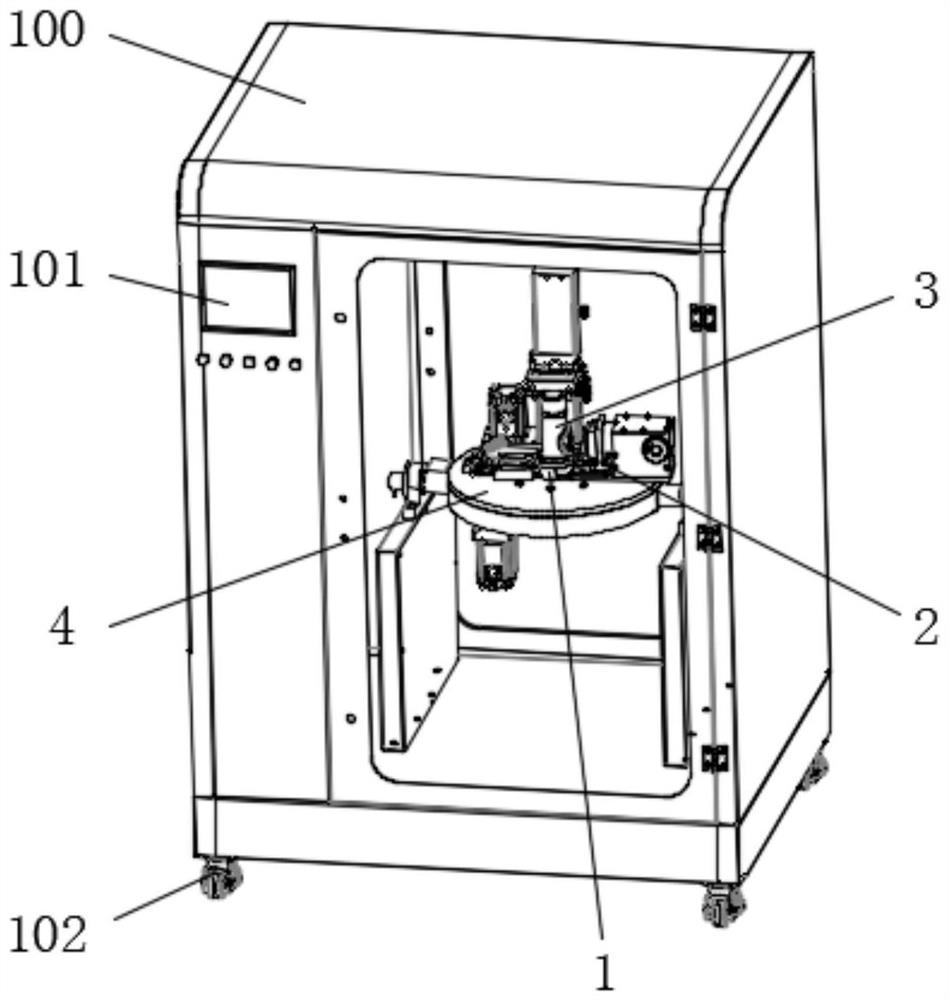

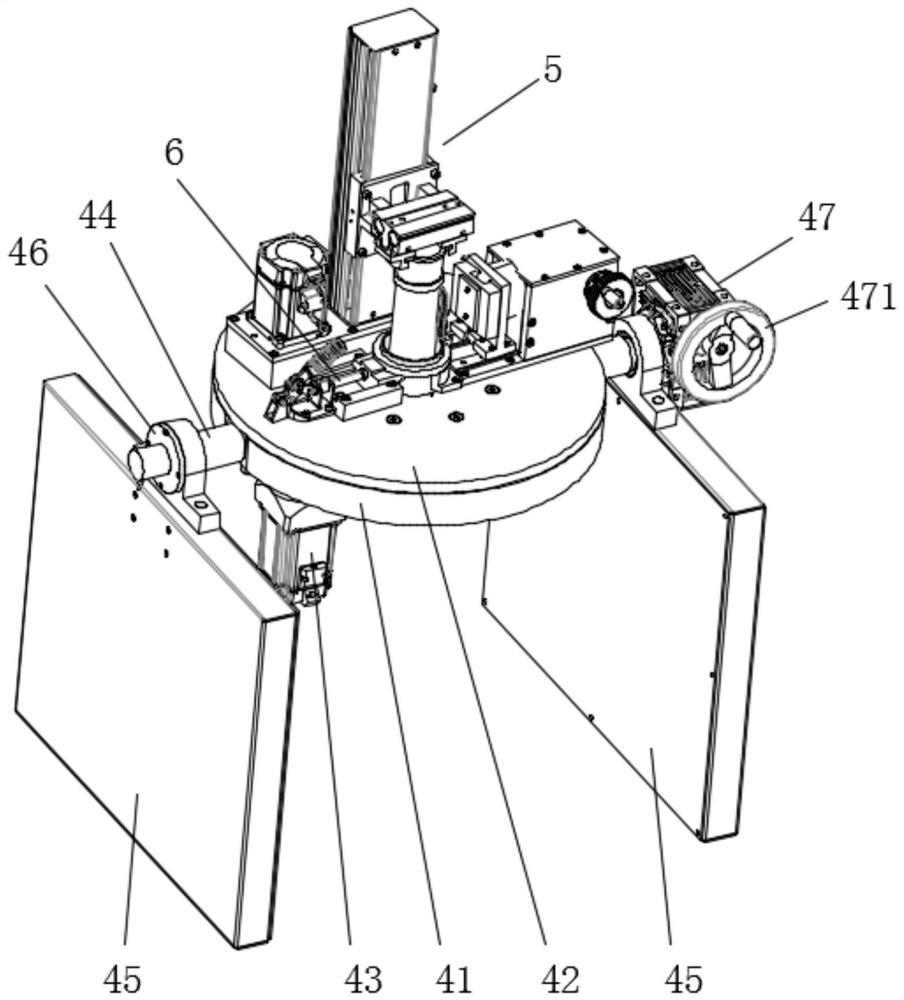

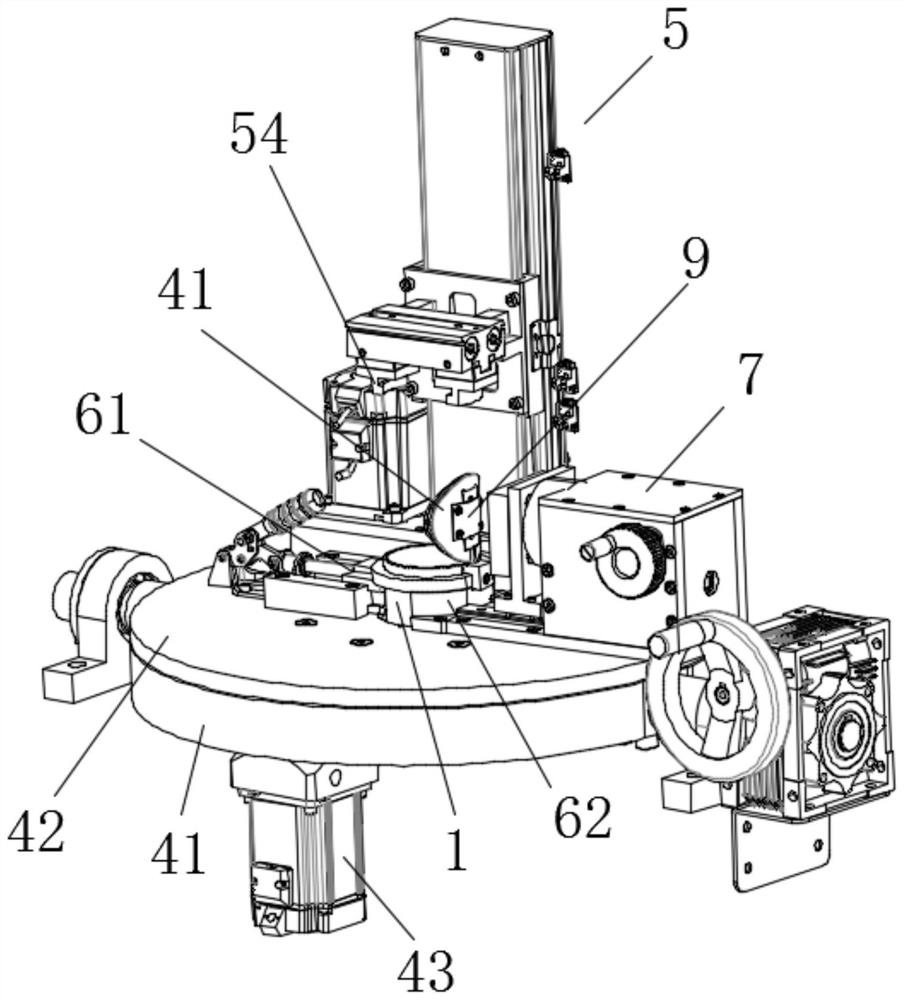

[0043] Such as figure 1 , figure 2 As shown, the magnetic closing performance testing equipment for the flap valve disclosed in this embodiment includes a box body 100 and a test bench. The test bench includes a platform 4, a valve seat fixing mechanism 6 for fixing the valve seat, and a core barrel driving mechanism 5 for driving the core barrel up and down.

[0044] The test bench is placed in the box body 100, and the box body 100 has an observation window. Putting the experimental platform in the box 100 has three functions: first, to realize the protection function. When the valve clack is closed, the air pressure is used to determine its pretightening force. second, to realize the modularization of the control mechanism, and to package each pneumatic and electric device in the box 100 to achieve a tidy and functional modular effect; third, the test bench not only has experimental functions, but also has certain functions. The valve seat closing action display functio...

Embodiment 2

[0082] The difference between this embodiment and Embodiment 1 is that: in this embodiment, the first base 41 and the second base 42 are disc-shaped. The first base 41 is arranged parallel to the second base 42 . The two rotating shafts 44 are radially disposed on opposite sides of the first base 41 .

[0083] The supporting seat 45 is a plate shape arranged vertically, and the bearing seat 46 is mounted on the top of the supporting seat 45 .

[0084]In the present invention, the spring that provides the initial closing power for the valve flap is replaced by a magnet. The repulsive force generated by the magnets repelling each other is far greater than the elastic force generated by the spring, that is, the magnetic potential energy generated between the magnets in the initial stage is relatively large. When drilling vertically or vertically upwards, enough energy can be provided to make the valve flap rotate and close against friction or gravity; in addition, the energy gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com