Processing equipment and processing technology of yellow dye for leather

A technology of yellow dye and processing equipment, which is applied in the direction of mixer with rotating stirring device, transportation, packaging, dissolution, etc. It can solve the problem of difficult mixing of two raw materials, low uniformity of finished dye, small initial contact area, etc. problem, to achieve the effect of improving uniformity, improving mixing degree, and easy mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

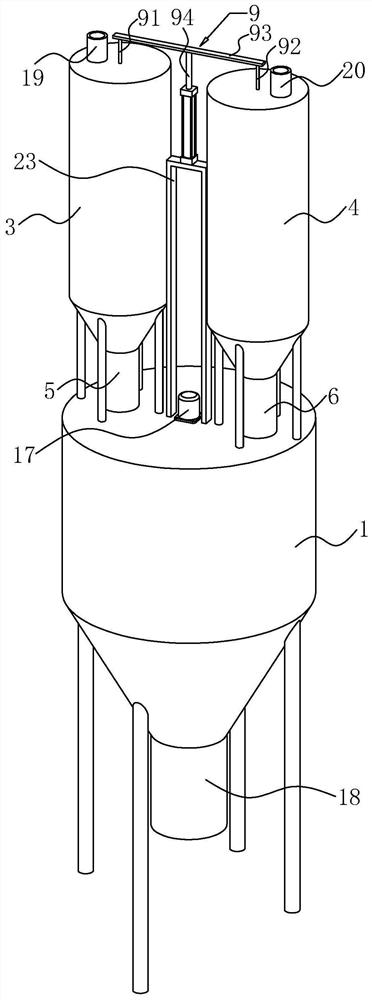

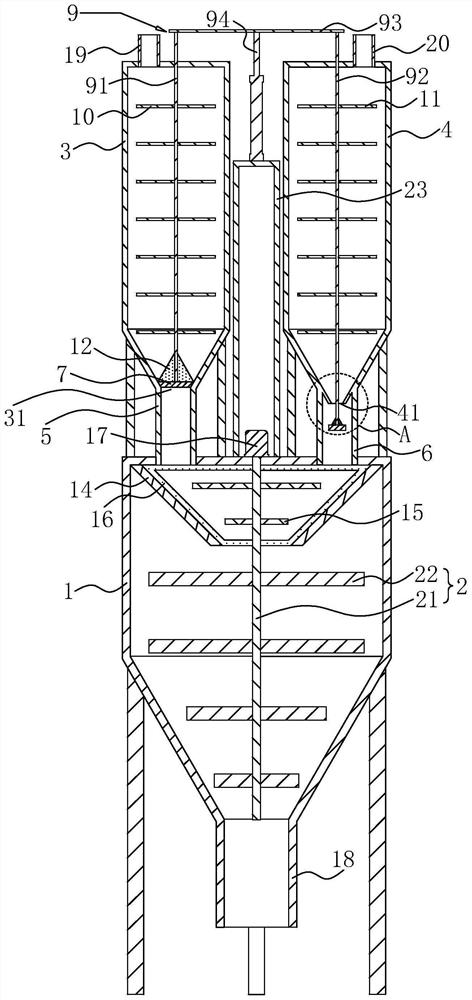

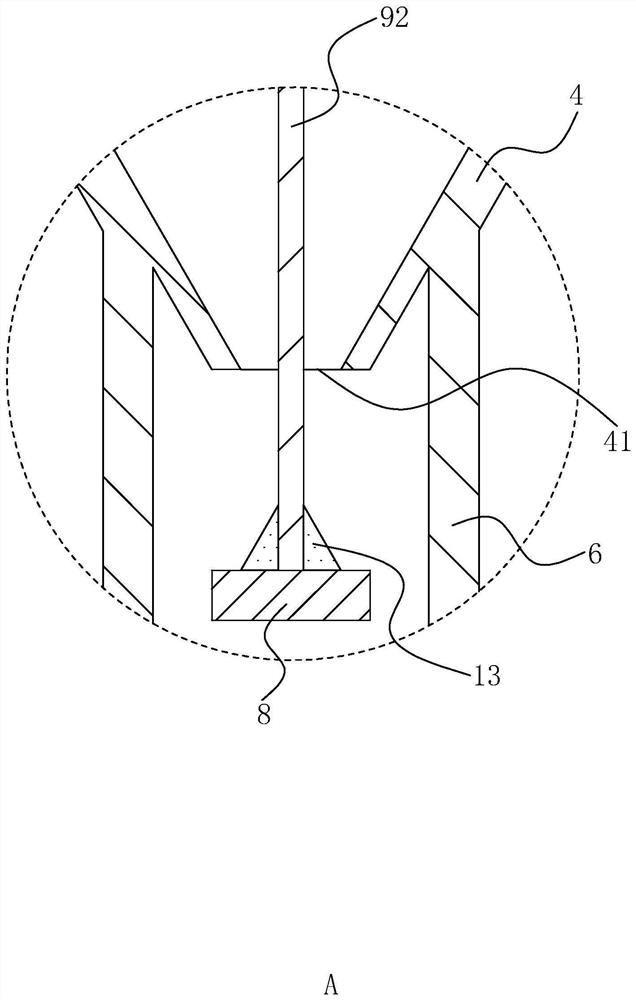

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] The embodiment of the present application discloses a processing equipment for yellow dye for leather. refer to figure 1 and figure 2 , the processing equipment comprises a mixing tank 1, the mixing tank 1 is provided with a stirring device 2, the top of the mixing tank 1 is fixedly provided with a driving motor 17 connected with the stirring device 2, and the driving motor 17 drives the stirring device 2 to rotate, so that the material Mix and stir. The top of the mixing barrel 1 is provided with a dye barrel 3 for holding yellow dye and an auxiliary agent barrel 4 for holding auxiliary agents, so that the mixing barrel 1 can be fed multiple times and in a small amount. The bottom of the mixing tank 1 is fixed with a discharge pipe 18 , and the uniformly mixed yellow dye and auxiliary agent can be discharged from the discharge pipe 18 of the mixing tank 1 .

[0041] ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com