Packaged food packaging inspection method and matched inspection equipment

A technology of inspection equipment and inspection methods, applied in the field of packaging and inspection, can solve the problems of labor-intensive labor, imperfect screening system, and lack of perfect procedures, etc., and achieve high screening accuracy, fast and convenient operation, and detection accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

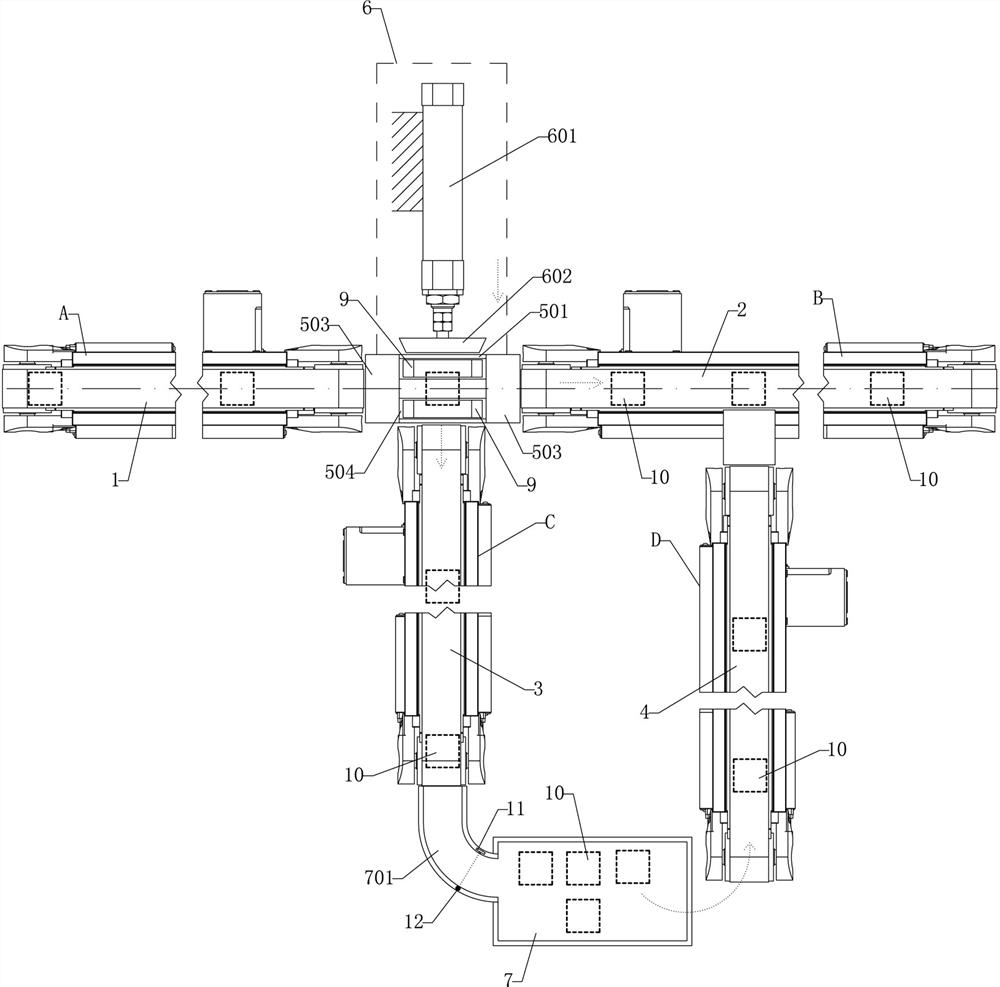

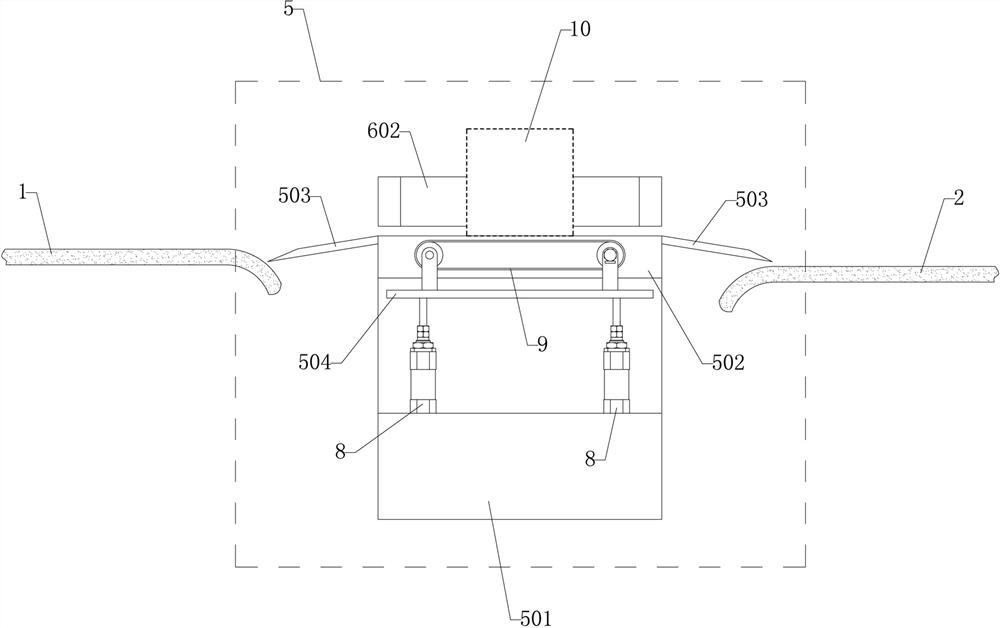

[0032] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0033] Such as Figure 1-2 As shown in, a packaged food packaging inspection method, comprising the following steps:

[0034] S1: After the food packaging process is completed, the upper-level conveying production line A, each packaging box 10 on the first-level conveying production line A is conveyed forward at a constant speed, and the interval between adjacent packaging boxes 10 needs to be controlled when discharging distance, so that adjacent packaging boxes 10 will not interfere or affect each other when electronic weighing is carried out in the later stage;

[0035] S2: The packaging box 10 on the first-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com