Waste plastic recycling equipment

A technology of recycling equipment and waste plastics, which is applied in the field of waste plastics recycling, can solve the problems of workers inhaling large dust, unfavorable environmental protection, and reduced performance, so as to achieve the effects of benefiting human health, promoting crushing efficiency, and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

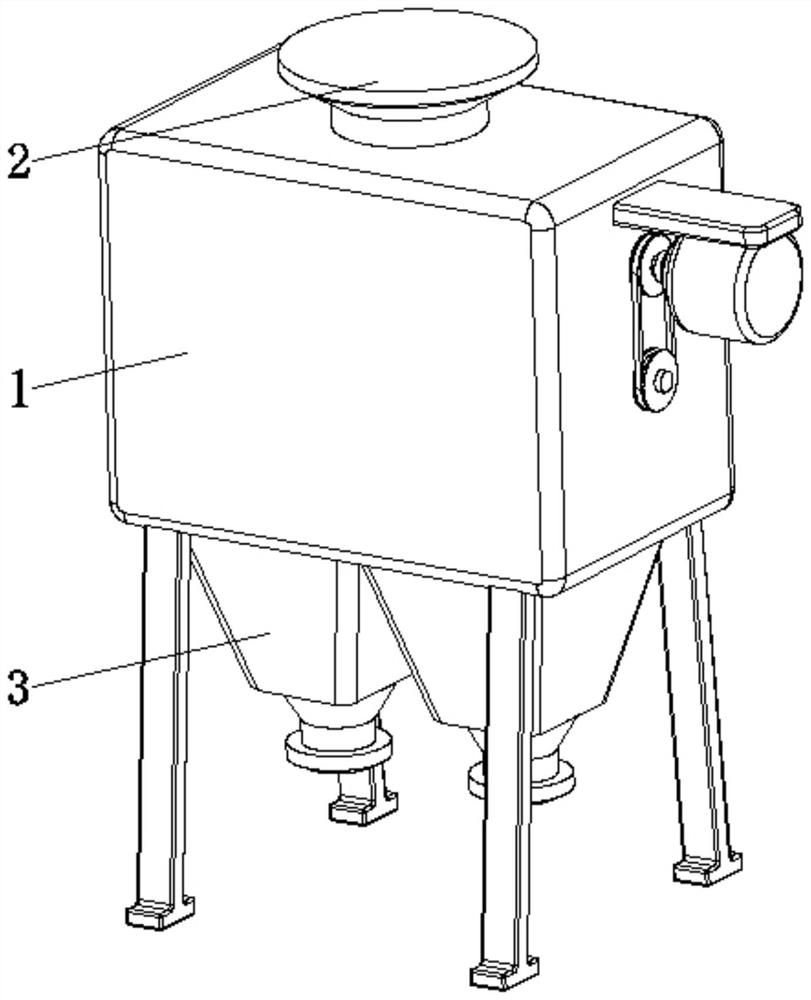

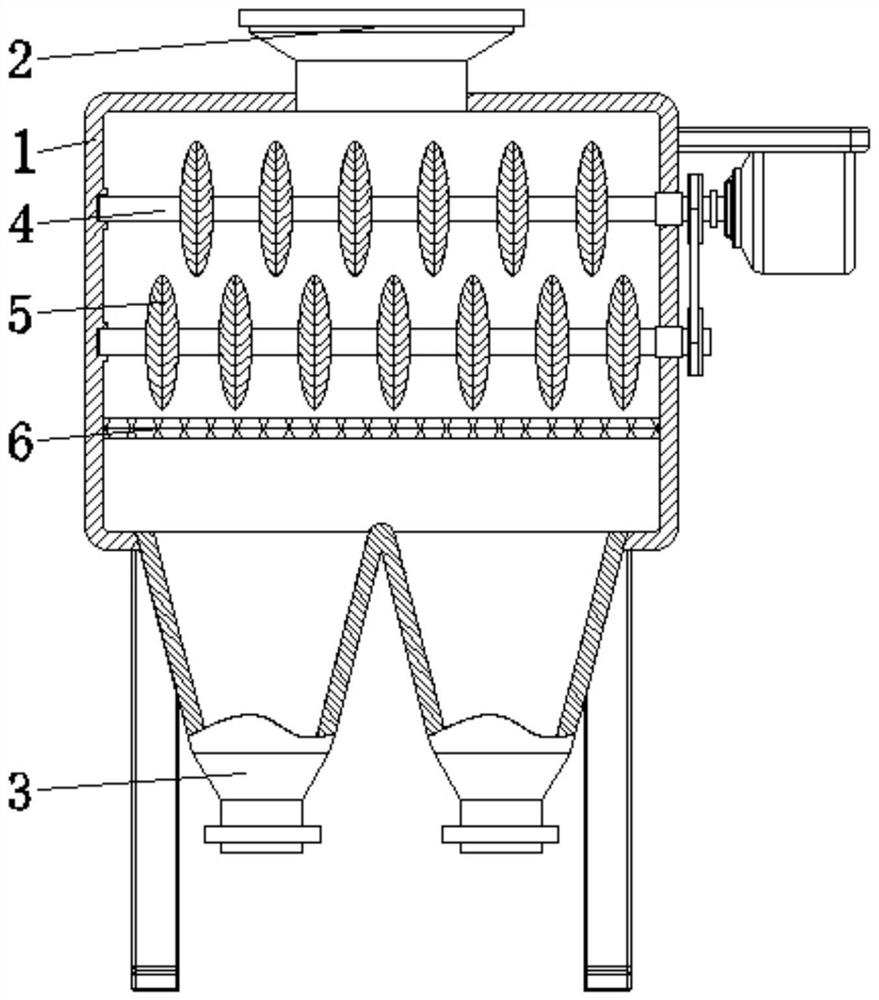

[0035] see Figure 1-7 , the present invention provides a technical solution: a waste plastic recycling equipment, including a crushing chamber 1, a feed hopper 2, and a discharge port 3, the feed hopper 2 is fixed at the top center of the crushing chamber 1, and the feed hopper 2 and The crushing chambers 1 are connected, and the discharge port 3 is set at the bottom center of the crushing chamber 1;

[0036] The interior of the crushing chamber 1 is provided with a driving shaft 4, a crushing device 5, and a screen 6, and the driving shaft 4 is rotatably connected between the corresponding two sides of the crushing chamber 1 and is close to the position of the feed hopper 2, and the crushing device 5 is fixed on On the surface of the drive shaft 4, the crushing device 5 is evenly distributed on the surface of the drive shaft 4 and arranged staggered up and down. The screen 6 is fixed on the inner wall of the crushing chamber 1 and is close to the position of the crushing dev...

Embodiment example 2

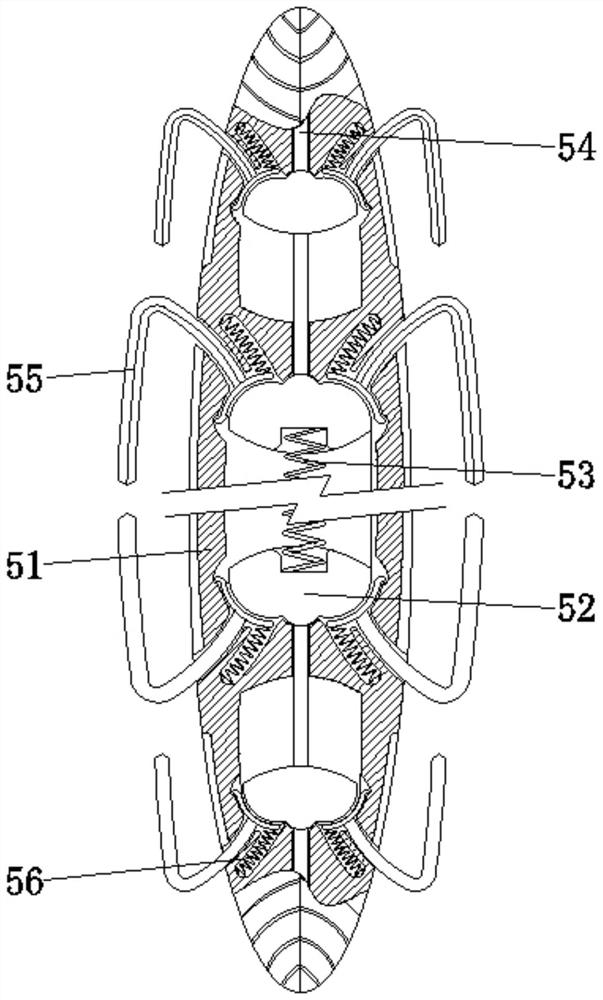

[0042] The auxiliary crushing knife device 55 is provided with a cutter body 551, a top plate 552, a blade slope 553, and a knife groove 554. The cutter body 551 is slidingly connected with the main crushing tooth 51. The top plate 552 is located inside the main crushing tooth 51 and is connected to the end of the cutter body 551 The blade slope 553 is provided on both sides corresponding to the surface of the cutter body 551, the knife groove 554 is provided on the surface of the blade body 551 and is located at the position of the blade slope 553, and the auxiliary crushing knife device 55 is easily pushed out by using the top plate 552 , is conducive to improving the crushing efficiency, the entire cutter body 551 can increase the crushing area of waste plastics, and the blade bevel 553 and knife groove 554 reduce the stress area, thereby making the crushing effect better.

[0043] When in use, first pour waste plastics from the feed hopper 2 into the crushing chamber 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com