Plastic product metal nut embedding machine

A technology for plastic products and nuts, which is applied in the field of metal nut implanters, can solve the problems that the position of plastic products affects the implantation effect, the metal nut falls off, and the function of marking the position before implantation is not available.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

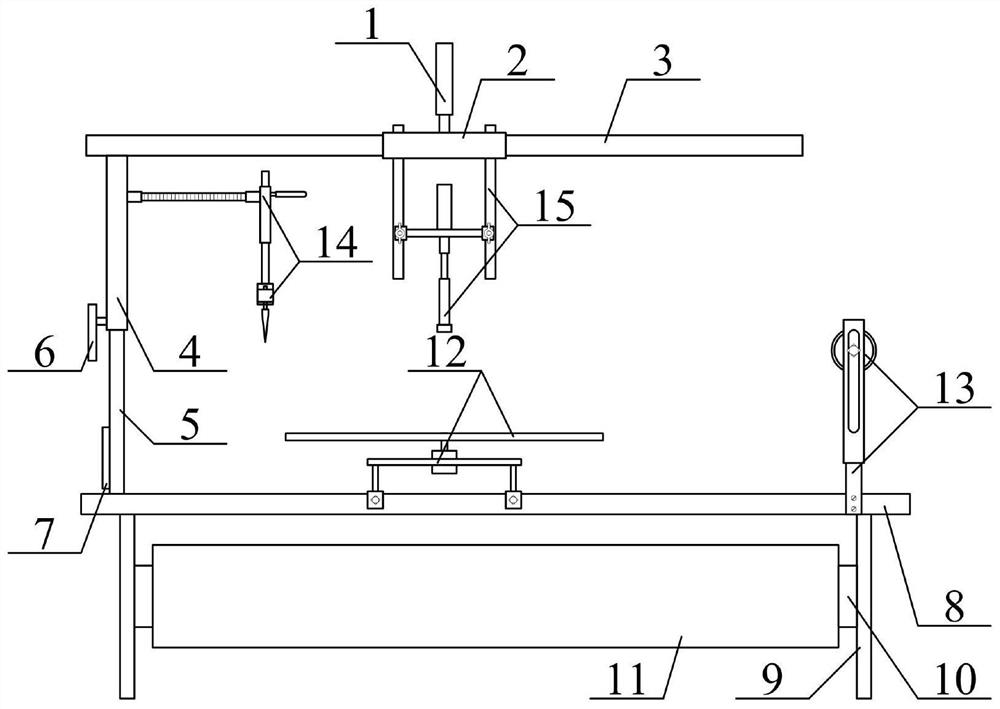

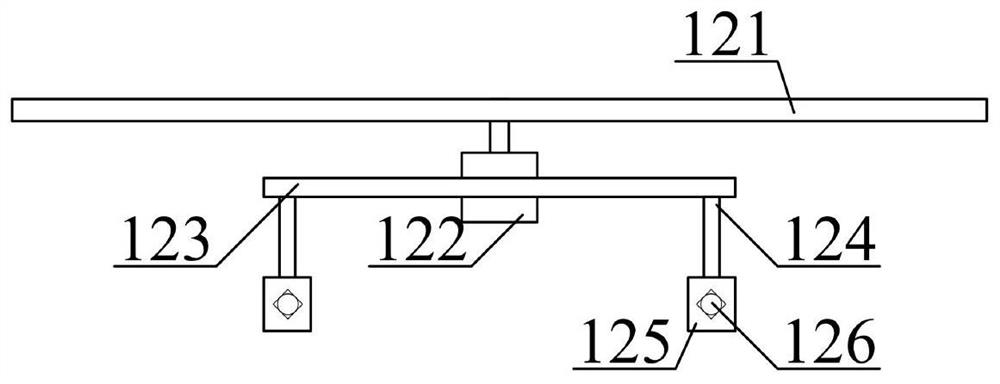

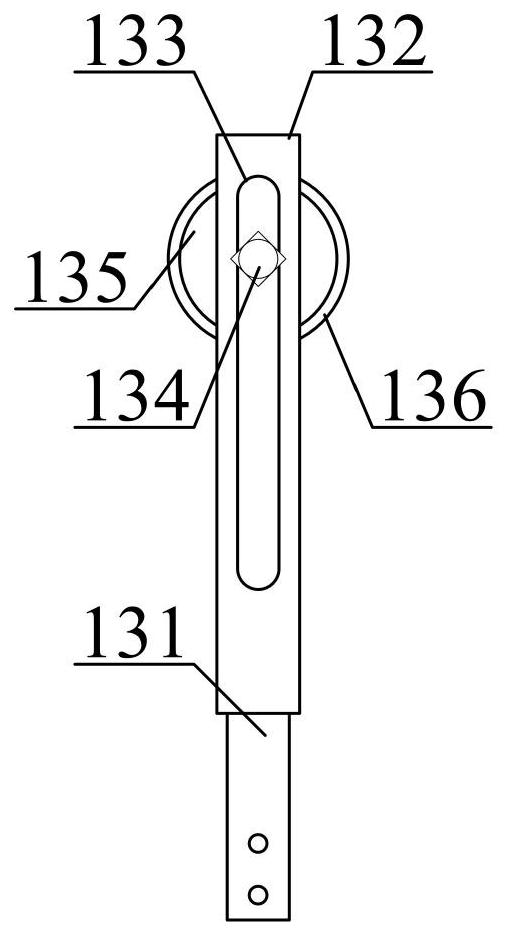

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, a metal nut embedding machine for plastic products includes a moving handle 1, a return slide 2, a beam 3, an adjustment tube 4, a support rod 5, an adjustment bolt 6, a control panel 7, a support lining 8, a support Leg 9, adsorption block 10, collection box 11, rotary adjustable plastic product embedding platform structure 12, adjustable plastic product surface cleaning wheel structure 13, adjustable plastic product embedding position marking head structure 14 and adjustable metal nut Embedding the pressure head structure 15, the longitudinal lower end of the moving handle 1 is threadedly connected to the upper middle part of the return-type slide 2; the return-type slide 2 is sleeved on the outer wall of the crossbeam 3; the crossbeam 3 is transversely The left bolt is connected to the upper end of the adjustment pipe 4; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com