LED down lamp label stamping equipment

A LED downlight stamping technology, applied in printing, stamping, etc., can solve the problems of uneven stamping of LED downlights, unqualified stamping of LED downlights, etc., and achieve good material loading or stamping, uniform loading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

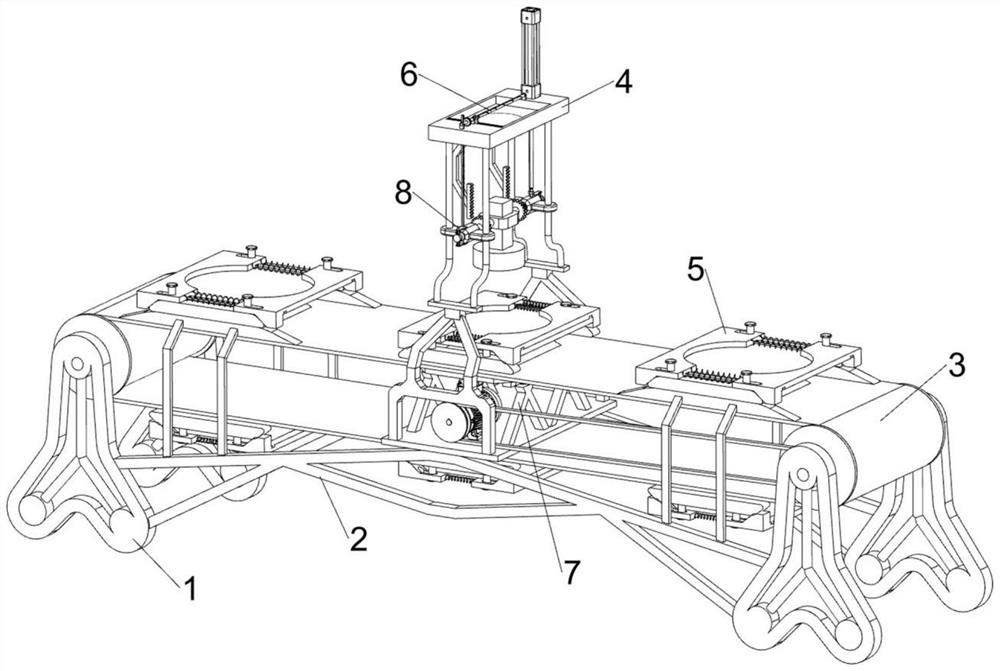

[0062] A LED downlight label stamping equipment, such as figure 1 As shown, it includes a bracket 1, a connecting rod 2, a moving component 3 and a stamping component 4, connecting rods 2 are arranged on the front and rear sides between the left and right brackets 1, a moving component 3 is arranged between the brackets 1, and the moving component 3 is provided with stamping assembly 4.

[0063] The worker first places the LED downlight on the moving component 3, and puts the paint in the stamping component 4, then the worker starts the moving component 3 to work, and the moving component 3 drives the LED downlight to move to the bottom of the moving component 3. At the same time, The staff starts the stamping component 4 to work, and the stamping component 4 moves downward to stamp the LED downlight. After the stamping component 4 is stamped, it resets upwards, and the moving component 3 drives the LED downlight to continue to move to the far left. The staff can take away an...

Embodiment 2

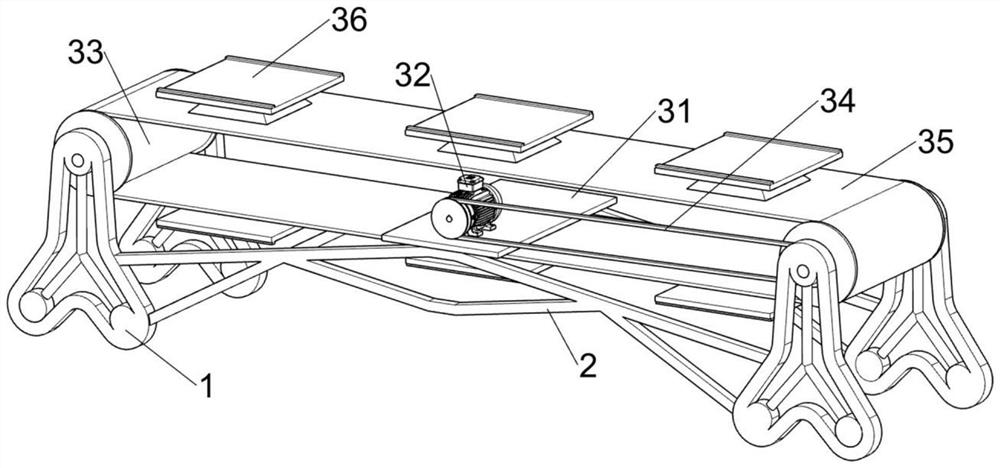

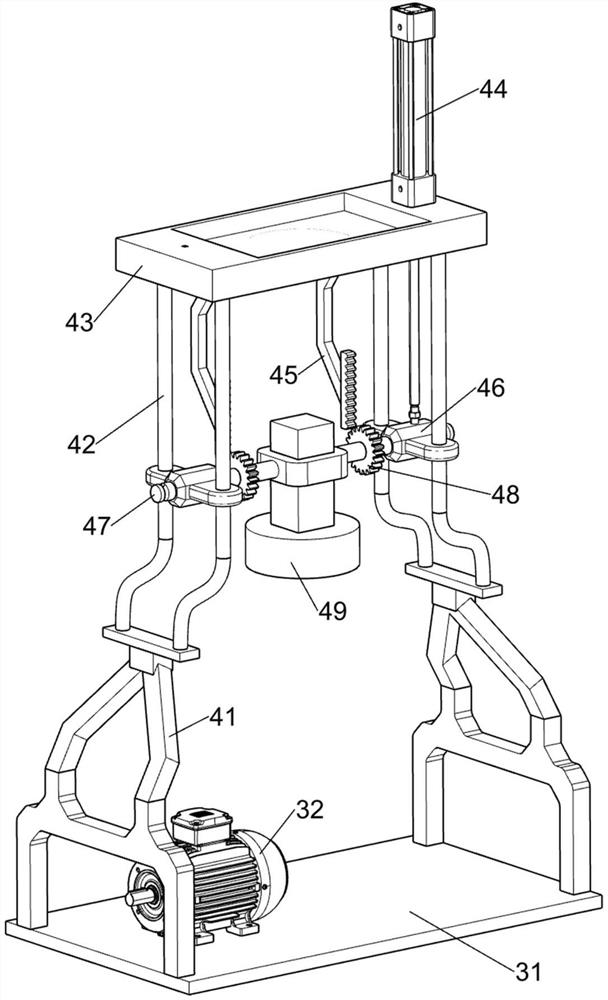

[0065] On the basis of Example 1, such as Figure 1-8As shown, the mobile assembly 3 includes a first fixed plate 31, a servo motor 32, a transmission wheel 33, a pulley assembly 34, a conveyor belt 35 and a placement table 36, and the first fixed plate 31 is arranged between the middle parts of the connecting rods 2 on the front and rear sides. , the front side of the top of the first fixed plate 31 is provided with a servo motor 32, and the upper part of the bracket 1 on the left and right sides is all rotatably provided with a transmission wheel 33, and a conveyor belt 35 is wound between the transmission wheels 33. A pulley assembly 34 is arranged between the front side of the output shaft of the servo motor 32 and the transmission shaft of the right transmission wheel 33 on the platform 36 .

[0066] The worker first places the LED downlight on the placement table 36, and fills the paint into the stamping assembly 4, then the worker starts the servo motor 32 to work, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com