Rubber coiled material splicing device and splicing method thereof

A splicing device and rubber technology, applied in the direction of bonding methods, adhesives, etc., can solve the problems of low splicing accuracy, unfavorable long-term use of rubber coils, and falling off, so as to enhance splicing quality, improve splicing accuracy, and prolong use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

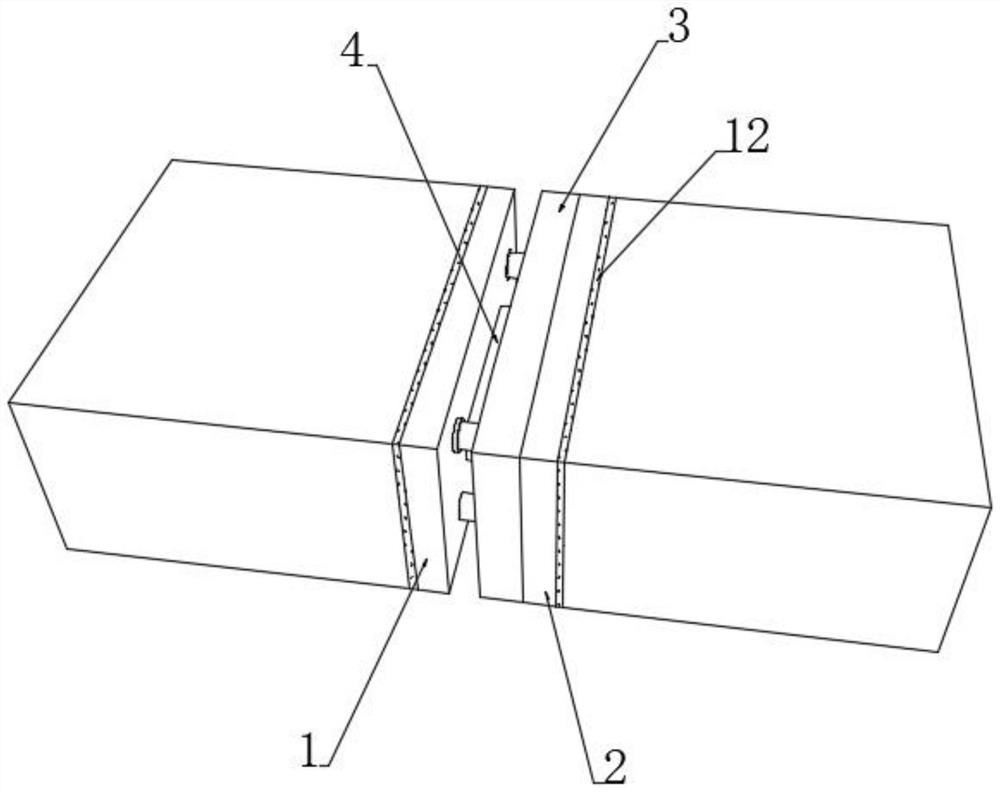

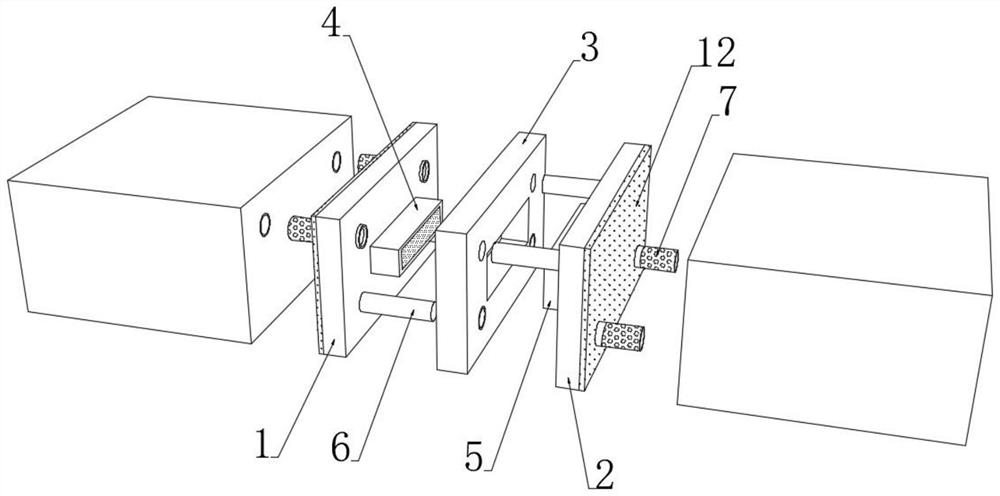

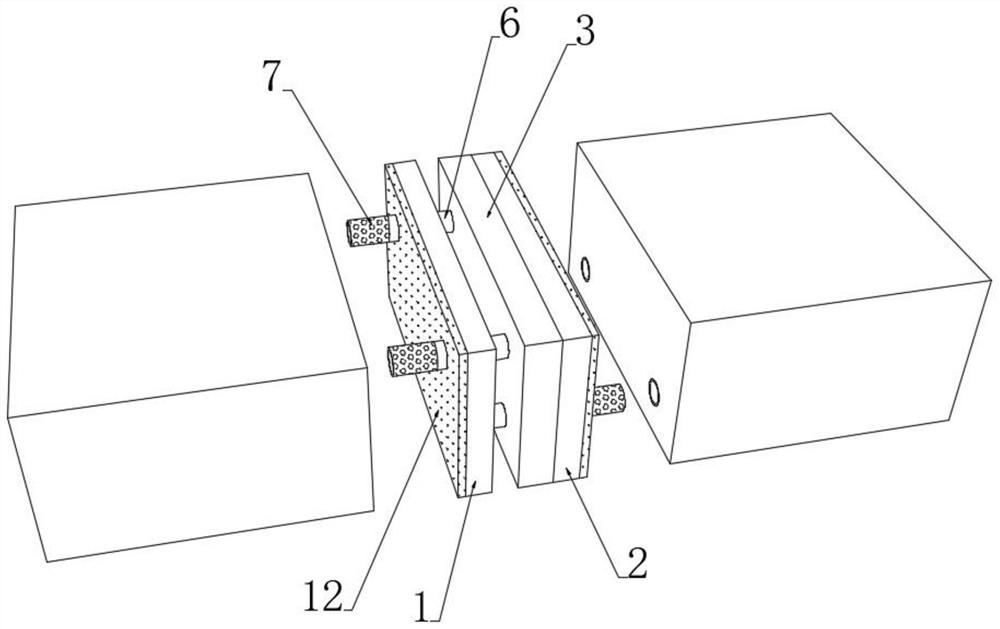

[0044] see Figure 1-4 , a rubber coil splicing device, comprising a left patch 1 and a right patch 2 arranged left and right, the left patch 1 and the right patch 2 are respectively connected to a pair of external rubber coils, and the left patch 1 and the right Adhesive surface layer 12 is attached to the opposite side of patch 2 and a pair of rubber coils, splicing plate 4 and adhesive storage plate 5 are respectively provided on the opposite side walls of left patch 1 and right patch 2 , the splicing plate 4 is matched with the bonded material storage plate 5 for movable embedded connection, and the end wall of the right patch 2 close to the left patch 1 is fixedly provided with a sealing plate 3 sleeved with the outer side of the bonded material storage plate 5 , the inside of the bonding material storage plate 5 is provided with a filling cavity corresponding to the position of the splicing plate 4, the inside of the filling cavity is filled with adhesive particle capsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com