A horizontal rotary pyrolysis reactor for domestic waste

A technology of rotary pyrolysis and domestic waste, which is applied to coke ovens with horizontal carbonization chambers, special forms of dry distillation, and charging devices, etc., which can solve the problems of small single-time processing capacity and low work efficiency of heating kettles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

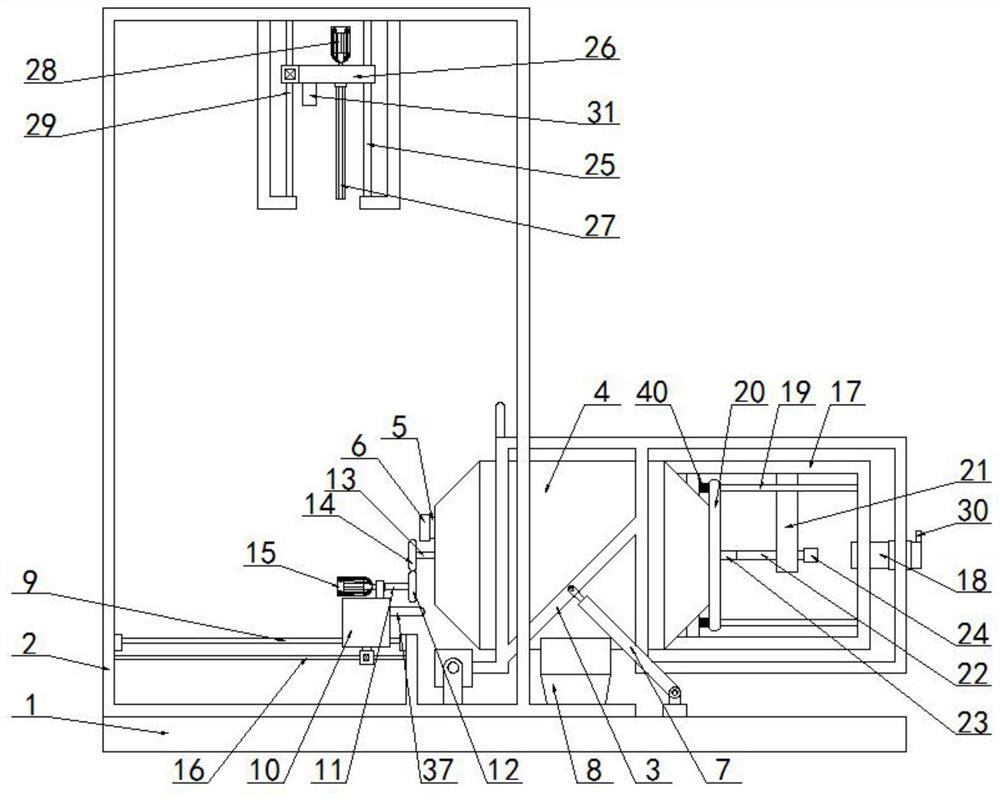

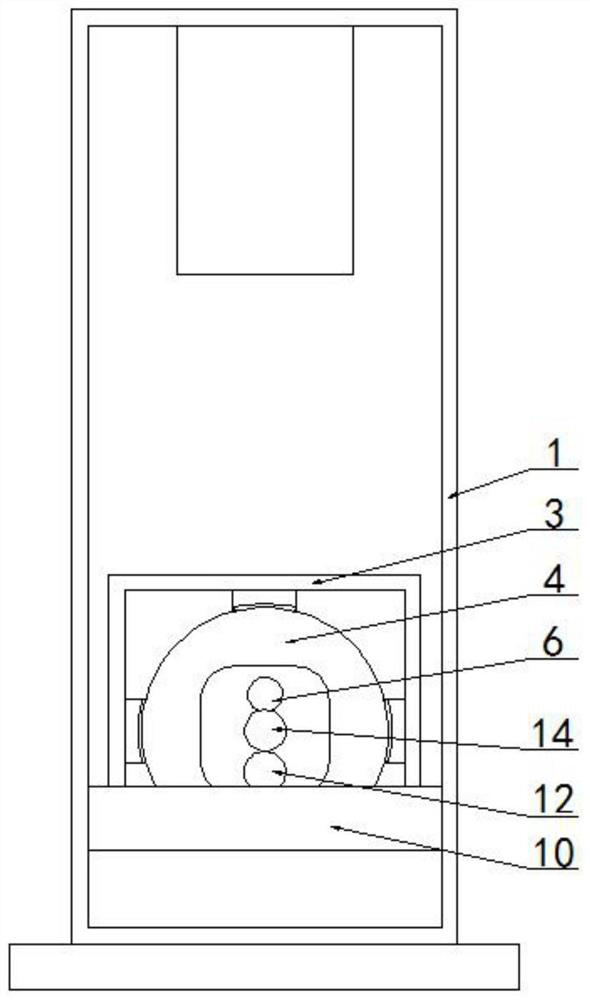

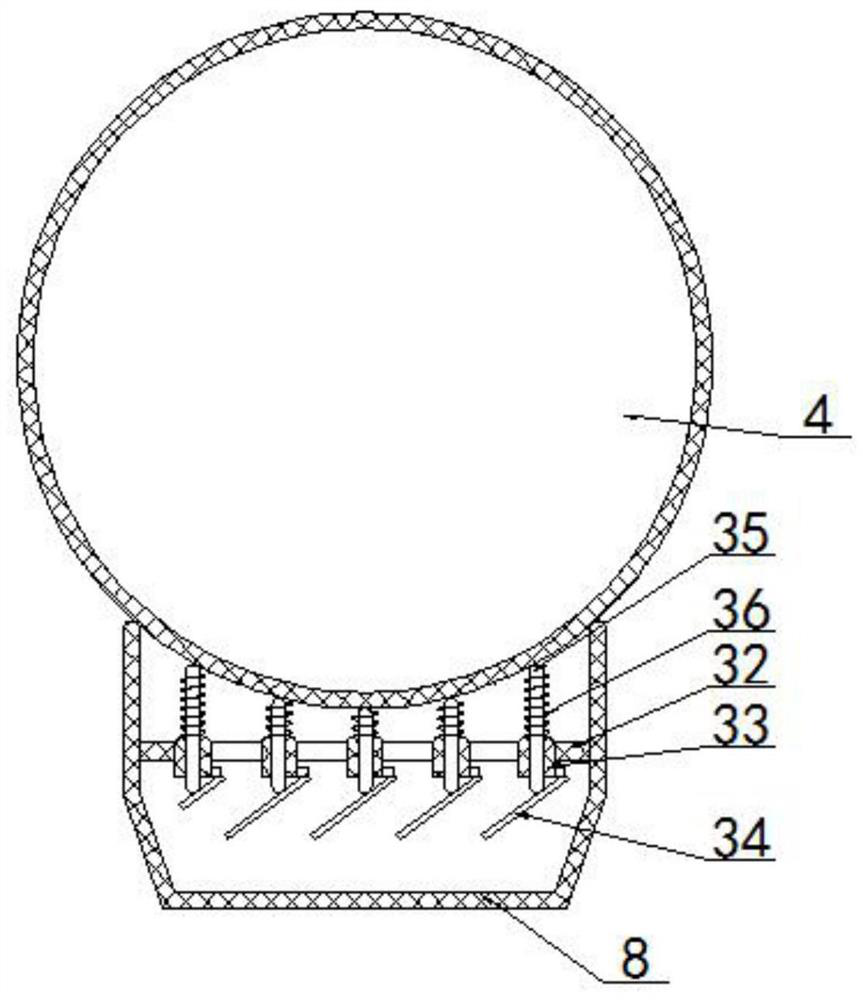

[0026] see as Figure 1-Figure 4 As shown, the specific embodiment comprises a base 1, a No. 1 support 2, a No. 2 support 3, a heating kettle 4, and a heating furnace 8, wherein a No. 1 support 2 is fixedly arranged on the base 1, and a No. 1 support 2 is rotated by a rotating shaft. No. 2 support 3, in No. 2 support 3, a heating kettle 4 is screwed through a bearing, and the right end opening of the heating kettle 4 is arranged, and a discharge pipe 5 is fixed on the left side wall of the heating kettle 4. On the discharge pipe 5 There is a sealing cover 6 screwed on the sleeve, the base 1 is screwed with the No. 1 electric push rod 7 through the rotating shaft, the output end of the No. 1 electric push rod 7 is screwed on the No. 2 bracket 3 through the shaft, and the No. 1 bracket 2 is fixed. A heating furnace 8 is provided, the upper end of the heating furnace 8 is opened, and the upper port of the heating furnace 8 is movable against the lower surface of the heating kettl...

specific Embodiment approach 2

[0035] see as Figure 5 As shown, the difference between this specific embodiment and the first specific embodiment is that the No. 1 gear 12 is replaced by a half gear 39, and the half gear 39 is fixedly arranged on the right end of the No. 1 rotating shaft 11, and the half gear 39 and the No. 2 gear 14 meshing setting, the length of the tooth segment of the half gear 39 is equal to the length of the tooth segment of the second gear 14, the first gear 12 is replaced by the half gear 39, the first motor 15 drives the half gear 39 to rotate through the first rotating shaft 11 , and then when the half gear 39 meshes with the second gear 14, it drives the heating kettle 4 to rotate, and when the half gear 39 disengages with the second gear 14, the heating kettle 4 stops rotating. The rotation is stopped permanently, which is convenient for the raw material deposition after stirring to be fully heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com