Chemical waste gas purification device and purification method

An exhaust gas purification device and exhaust gas purification technology are applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve problems such as air pollution, secondary pollution, and limited treatment effect, so as to increase the contact area and avoid pollution. Air, to achieve the effect of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

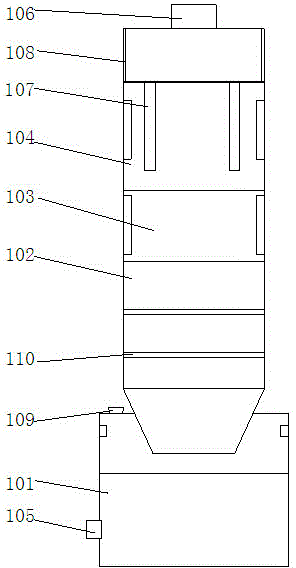

[0028] Such as figure 1 As shown, a chemical waste gas purification device includes a spray chamber 101, a drying chamber 102, a heating chamber 103 and an adsorption chamber 104 arranged sequentially from bottom to top;

[0029] The spray chamber 101 is provided with a water storage tank, and the lower part of one side of the spray chamber 101 is provided with a waste gas inlet 105, and the waste gas inlet 105 is provided with a high-pressure pump, and the inner wall of the spray chamber 10) There is a spray pump on it;

[0030] The drying chamber 102 is provided with a desiccant, and the drying chamber 102 is provided with at least two isolation boards 110, and the isolation boards 110 divide the drying chamber 102 into at least three chambers. A desiccant is provided in the room, and the isolation plate 110 is a double-layer thin plate provided with through holes;

[0031] The inner wall of the heating chamber 103 is provided with electric heaters, and the electric heater...

Embodiment 2

[0038] A method for purifying chemical waste gas, comprising the following steps:

[0039] S1: Acidify the waste gas, pass the waste gas into the spray chamber 101 with acid solution, make the aqueous solution in the spray chamber absorb the solid particles in the waste gas, and absorb the nitrogen oxides in the waste gas through the acid solution, Start the induced draft fan to suck the air in the adsorption chamber 104, so that negative pressure appears in the adsorption chamber;

[0040] S2: The exhaust gas processed in step S1 is passed into the drying chamber 102, and the moisture in the exhaust gas is absorbed by at least three layers of desiccant, and the dried exhaust gas enters the heating chamber 103 after passing through the air heater, and is heated by the electric heating in the heating chamber 103 The device heats the exhaust gas at high temperature to decompose the hydrocarbons and methane in the exhaust gas, and passes the decomposed gas into the adsorption cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com