Preparation method of pure straw biomass type fuel carbon

A biomass and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low cost, pollution, high thermal efficiency, etc., and achieve the effects of low cost, solving the greenhouse effect, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

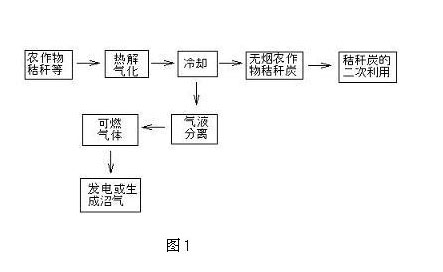

[0011] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the present invention is a preparation of pure straw biomass fuel charcoal. The method is as follows: putting crop straw (including corn straw, wheat straw, straw, leaves, etc.) The pyrolysis gasification reaction is carried out under processing conditions, the solid is cooled to obtain straw charcoal, and the gas obtained after the pyrolysis gas is separated from gas and liquid can generate electricity or biogas. Straw charcoal can be used directly and can be fully burned without black smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com