Method for converting waste flue gases into gases similar to air

A waste flue gas and air technology, applied in the direction of combustion method, separation method, air quality improvement, etc., can solve the problems of high cost, low practicability, and rising barriers, and achieve the goal of changing pollution, avoiding greenhouse effect, and low application cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

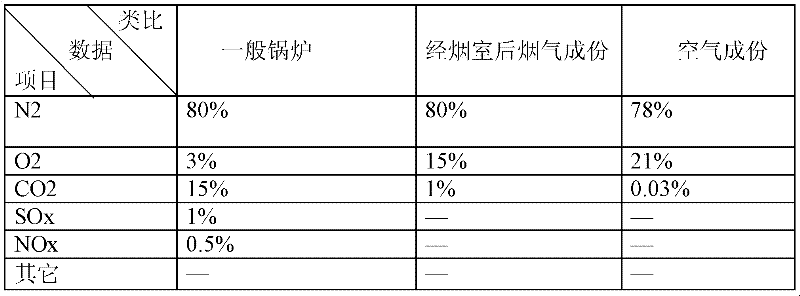

[0024] A method for converting waste flue gas into an air-like gas, the steps are as follows:

[0025] A. Accelerator A is a compound alkaline agent, including potassium hydroxide, sodium hydroxide, and calcium hydroxide. Accelerator B is a complex of strong reducing substances, including low sodium sulfite and sodium sulfite. B and water are poured into a mixing container in a ratio of 1:1:50. The container can be designed according to the size of the boiler. Generally, a boiler with an evaporation capacity of 10 tons per hour should use a 10 cubic mixing container. The flue gas is introduced into the flue gas mixing tank through the induced draft fan. At this time, the flue gas and the combustion accelerator solution enter the lower layer of the "device for converting waste flue gas into air-like gas" through the flue inlet pipe at the same time. This device has applied for a patent at the same time. The "device for converting waste flue gas into air-like gas" has several ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com