Lead-carbon battery composite negative electrode additive and lead-carbon battery negative electrode and its preparation and application

A compound additive and lead-carbon battery technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of specific capacity decline and low surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

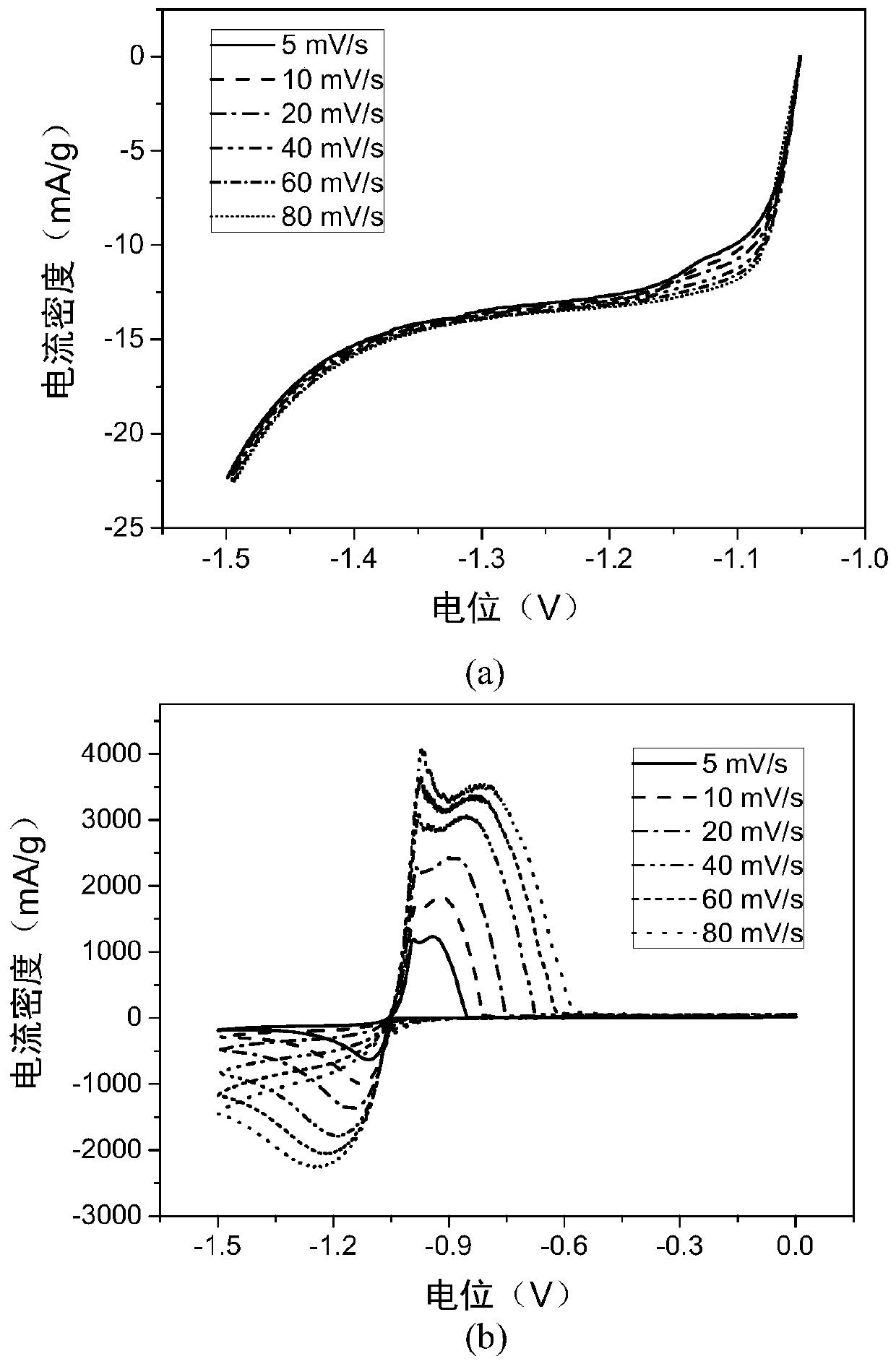

Embodiment 1

[0053] Weigh 0.3 g of analytically pure cerium nitrate, add it into 100 mL of deionized water, stir well until completely dissolved, and obtain a cerium nitrate solution. Weigh 20 g of analytically pure disodium ethylenediaminetetraacetic acid (EDTA), add it into 300 mL of deionized water, stir well until it is completely dissolved, and obtain an EDTA solution. Add the prepared cerium nitrate solution into the EDTA solution and stir for 30 minutes to make the cerium ions fully complexed by EDTA. Then, 7.8 g of graphene oxide dispersion liquid with a concentration of 3.86 wt % was added to the above solution, stirred while heating, and water was removed to obtain composite additive precursor powder. Put the obtained additive precursor powder in N 2 Calcined at 800° C. for 5 h in a protective atmosphere to obtain a graphene-based composite additive. 100g of lead powder, 1.5g of graphene-based composite additives, 1.4g of barium sulfate, and 0.05g of short polypropylene fibers ...

Embodiment 2

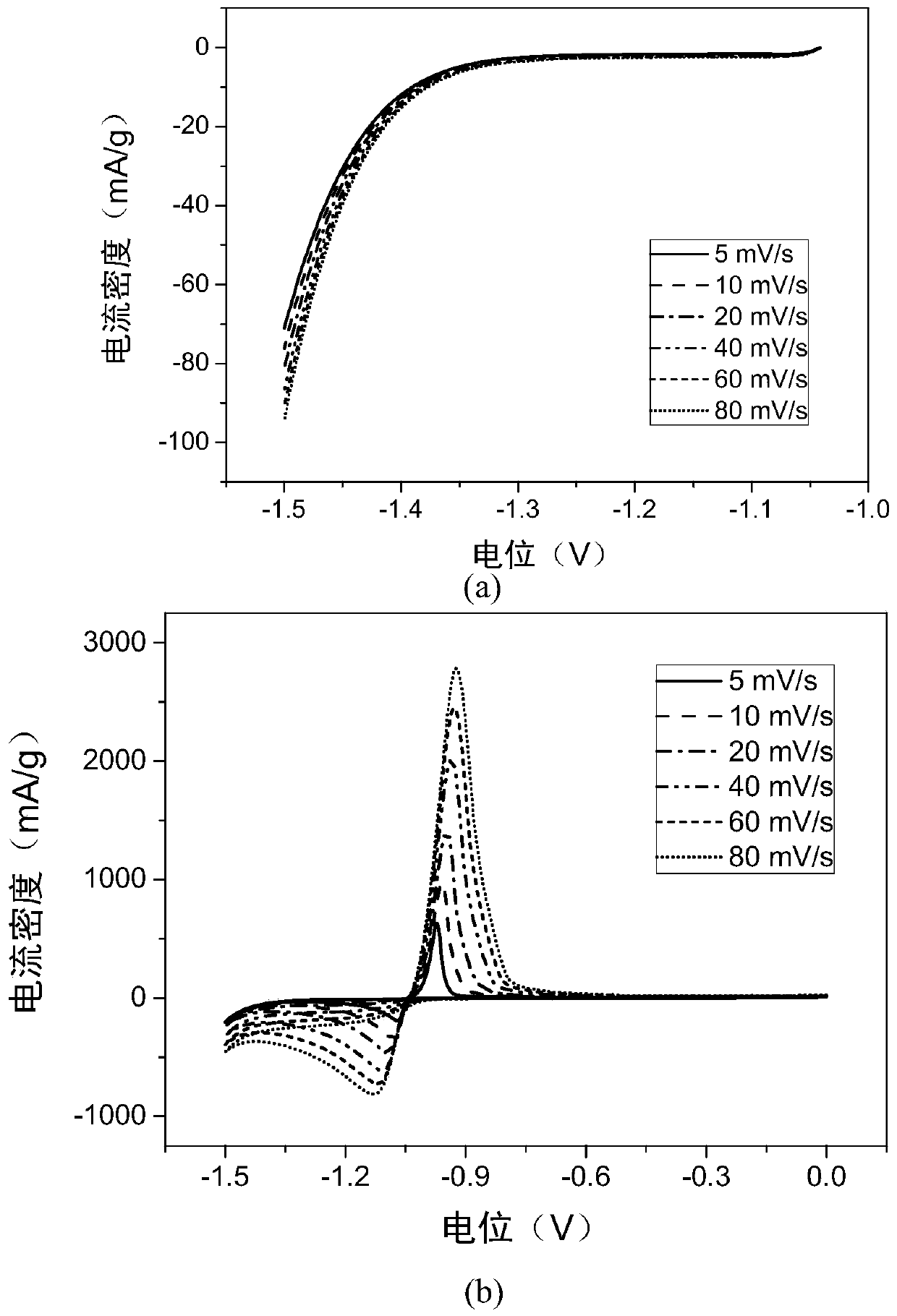

[0055] Weigh 0.3 g of analytically pure lead nitrate, add it into 100 mL of deionized water, and stir until completely dissolved to obtain a lead nitrate solution. Weigh 20 g of analytically pure disodium ethylenediaminetetraacetic acid (EDTA), add it into 300 mL of deionized water, stir well until it is completely dissolved, and obtain an EDTA solution. Add the prepared lead nitrate solution into the EDTA solution and stir for 30 minutes to make the lead ions fully complexed by EDTA. Then, 7.8 g of graphene oxide dispersion liquid with a concentration of 3.5 wt % was added to the above solution, stirred while heating, and water was removed to obtain composite additive precursor powder. Put the obtained additive precursor powder in N 2 Calcined at 800° C. for 5 h in a protective atmosphere to obtain a graphene-based composite additive. 100g of lead powder, 2.0g of graphene-based composite additives, 1.4g of barium sulfate, and 0.05g of short polypropylene fibers with a lengt...

Embodiment 3

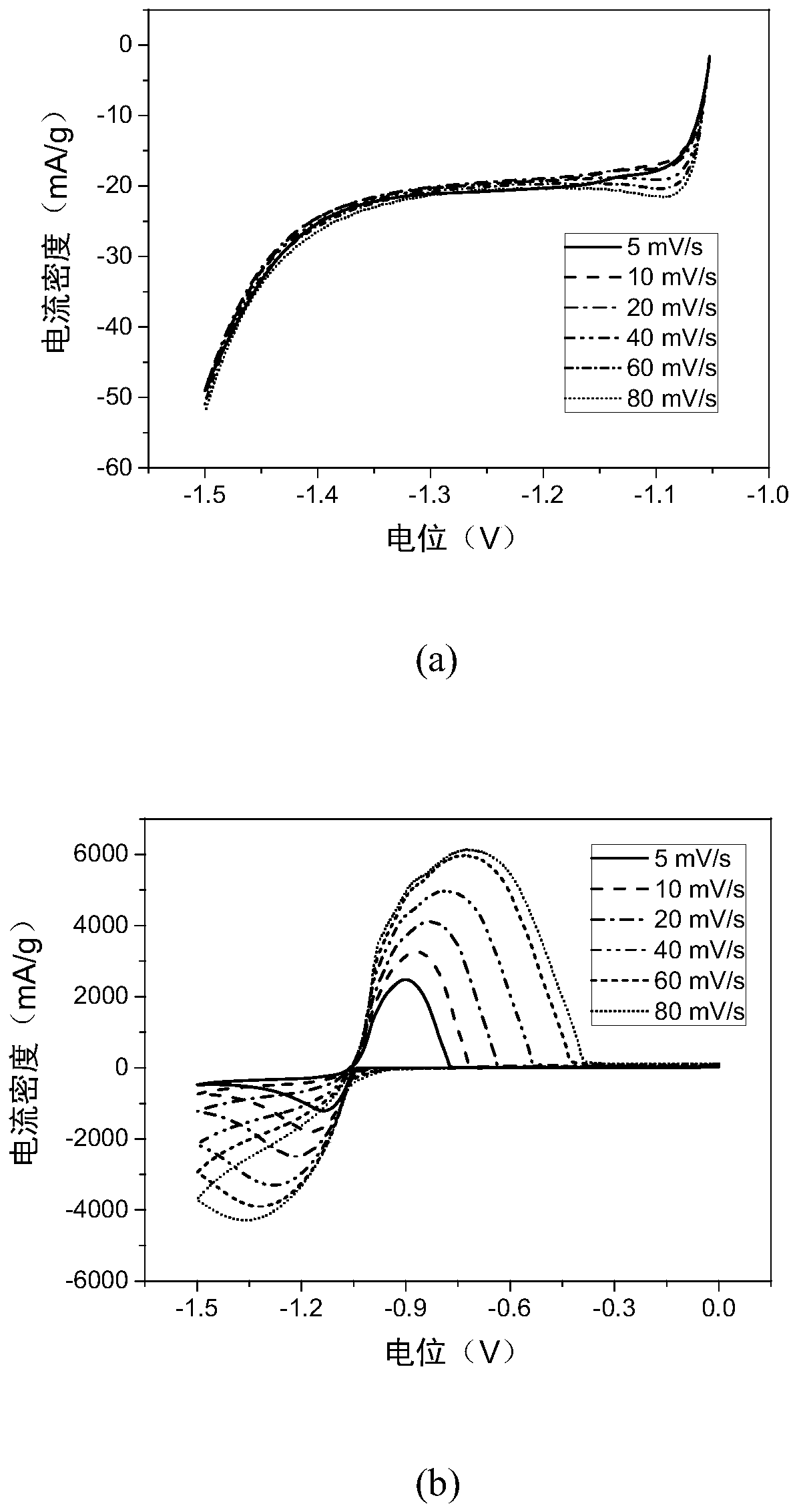

[0057] Weigh 0.3 g of analytically pure lead nitrate, add it into 100 mL of deionized water, and stir until completely dissolved to obtain a lead nitrate solution. Weigh 20 g of analytically pure disodium ethylenediaminetetraacetic acid (EDTA), add it into 300 mL of deionized water, stir well until it is completely dissolved, and obtain an EDTA solution. Add the prepared lead nitrate solution into the EDTA solution and stir for 30 minutes to make the lead ions fully complexed by EDTA. Then, 3.9 g of graphene oxide dispersion liquid with a concentration of 3.5 wt % was added to the above solution, stirred while heating, and water was removed to obtain composite additive precursor powder. Put the obtained additive precursor powder in N 2 Calcined at 800° C. for 5 h in a protective atmosphere to obtain a graphene-based composite additive. 100g of lead powder, 1.5g of graphene-based composite additives, 1.4g of barium sulfate, and 0.05g of short polypropylene fibers with a lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com