Dry operation cast-in-situ bored pile hole bottom sediment soil sampling device

A technology of bored cast-in-place piles and earth-taking devices, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve problems such as time constraints, inability to bring out sediment at the bottom of holes, and narrow construction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

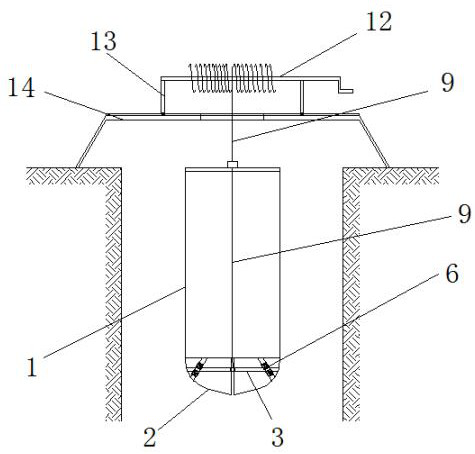

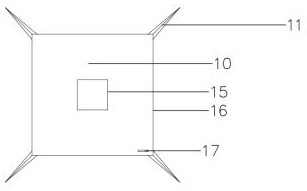

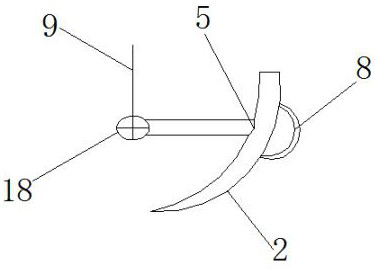

[0028] Such as Figure 1-Figure 4 As shown, this embodiment provides a device for extracting soil from the bottom of bored pile holes in dry operation, including a soil extraction cylinder 1, the top of the soil extraction cylinder 1 is connected to a cross roof 7, and the center of the top of the cross roof 7 is connected to a crane. Rope 4, the outer wall of the end of the soil borrowing cylinder 1 is hinged to several vertically arranged arc-shaped steel plates 2. In this embodiment, three pieces are used as an example. Of course, it can also be set according to needs. The ends of the arc-shaped steel plates 2 are The tip, the inner wall of the arc-shaped ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com