Strip mine end slope thin coal seam dendritic reverse type underground mining method

A technology for open-pit mines and thin coal seams, which is used in surface mining, mining equipment, earth-moving drilling, etc., can solve the problems of low efficiency and poor safety of end-assisted coal pressing mining, and achieves reduction of engineering cost, difficulty, and improvement of coal output. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

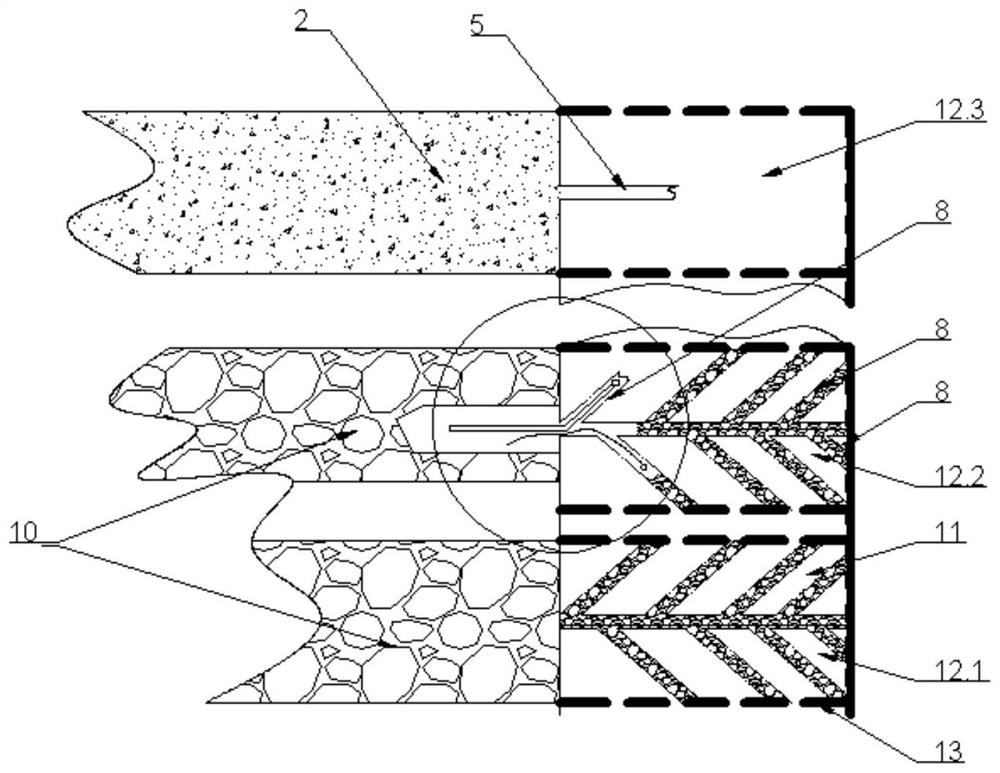

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

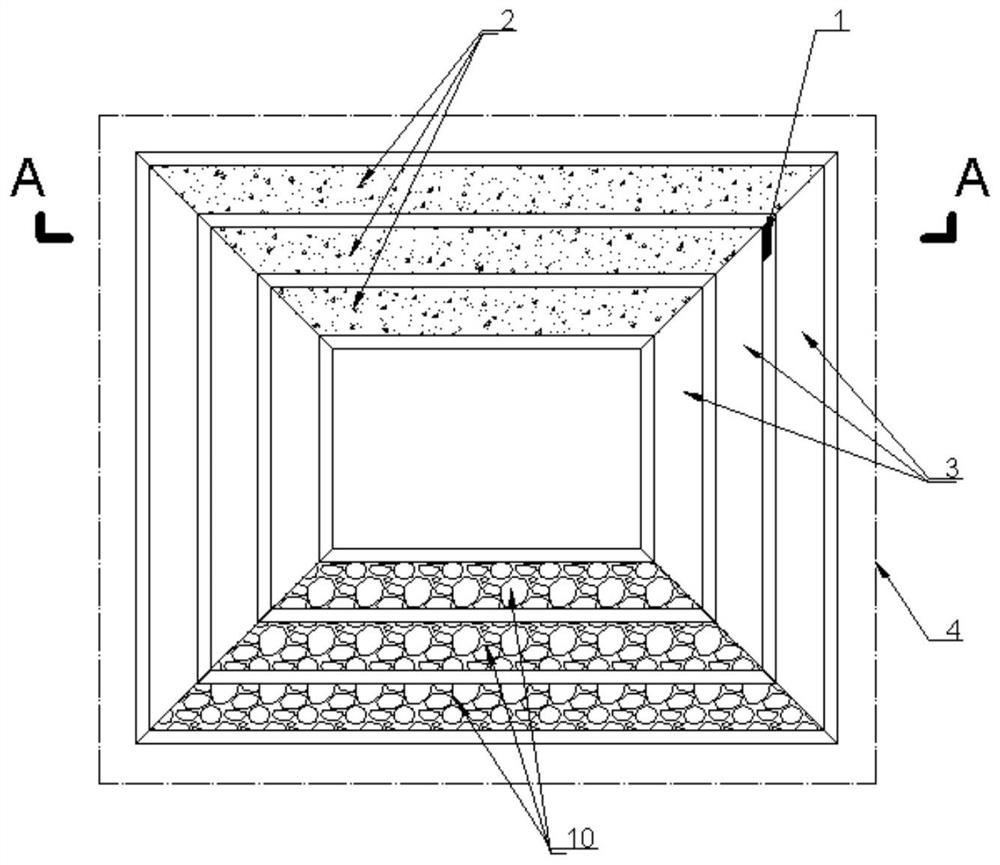

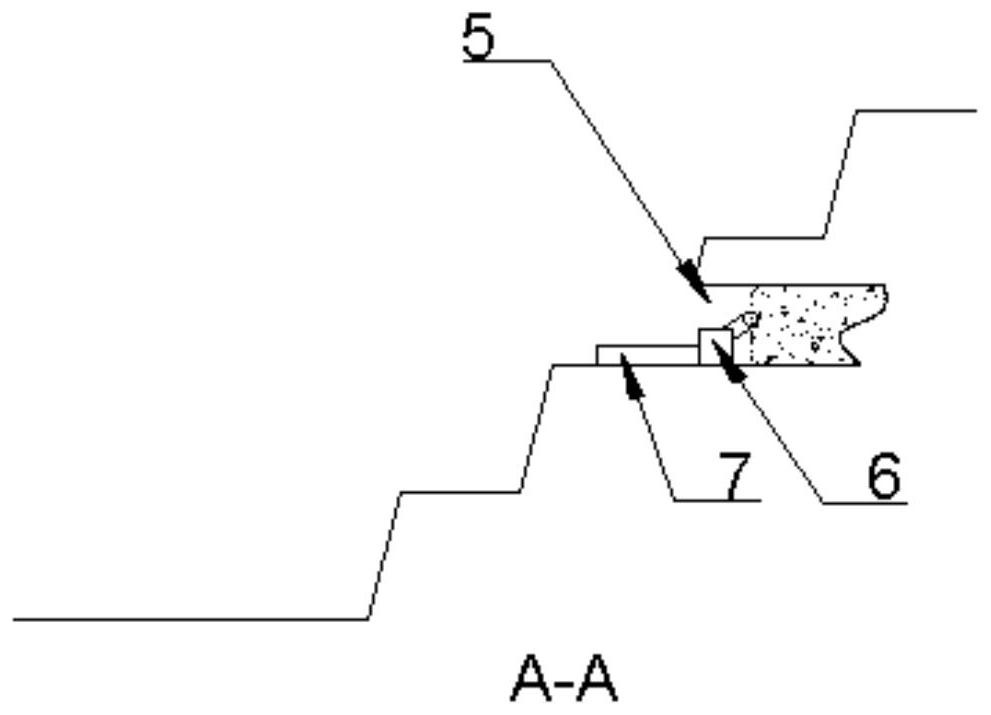

[0024] Such as figure 1 , 2 As shown, a dendritic retrograde adit mining method with thin coal seams at the side of the open-pit mine, including the development of the main adit 5 and the arrangement of mining and transportation equipment, the arrangement of the secondary adduct 8, coal mining and transportation, equipment relocation, post-mining filling and Blocking the main ark 5 and other links, the details are as follows:

[0025] S1: Divide the open-pit side coal pressing along the advancing direction of the open-pit mine into several recovery mining areas at intervals of 80-100m. 1 After the initial exposure width reaches 5m, starting from the exposed coal position of the open-pit mine side 3, the remote-controlled continuous coal mining machine 6 is used to excavate the main adit 5 along the coal seam floor to the boundary of the open-pit mine. shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com