Transmission power transmission system, transmission and vehicle

A power transmission system and transmission technology, applied in the field of vehicle engineering, can solve the problems of limited efficient working range of motors, increased vehicle power consumption, low-speed start acceleration, and high-speed cruising speed performance cannot be taken into account.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

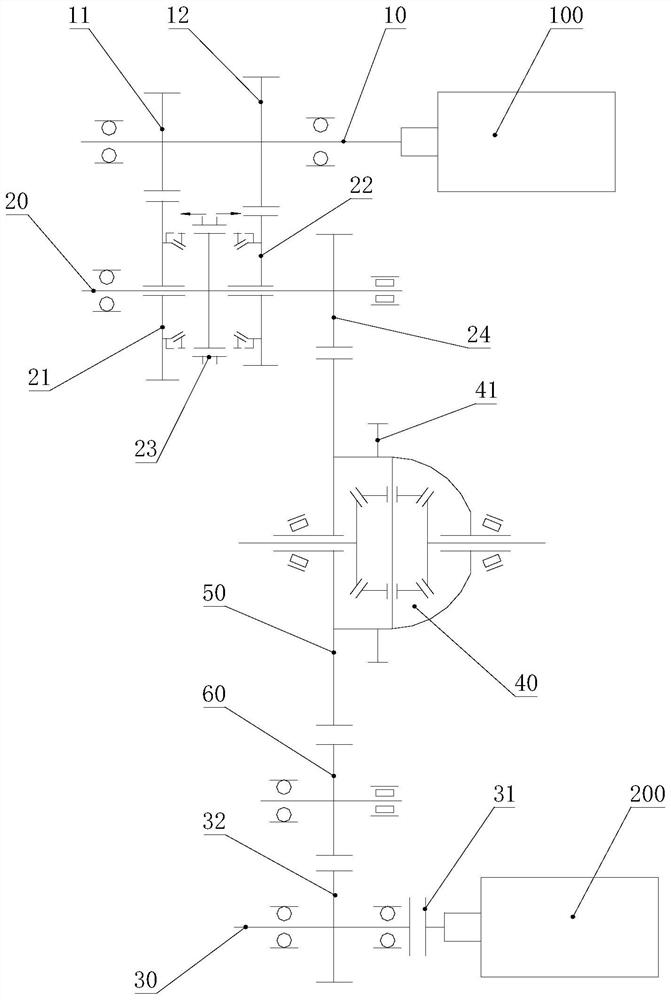

[0037] combine figure 1, the present embodiment provides a transmission power transmission system, including a first input shaft 10, an intermediate shaft 20, a reduction gear set and a second input shaft 30; Gears, the intermediate shaft 20 is sequentially provided with a plurality of gear driven gears along its length direction, and the multiple gear driven gears mesh with a plurality of gear driving gears one by one, and the intermediate shaft 20 is connected to the reduction gear set. ; The intermediate shaft 20 is provided with a synchronizer 23, and the synchronizer 20 is used to selectively drive one of a plurality of gear driven gears to be connected to the intermediate shaft 20; the second input shaft 30 is connected to the reduction gear set, and the second The input shaft 30 is provided with a clutch 31 for transmission connection with a power input device.

[0038] Wherein, the first input shaft 10 is supported on the case body of the transmission through bearings...

no. 2 example

[0056] This embodiment provides a transmission, including the transmission power transmission system described in the first embodiment, so that the transmission can switch gears according to the speed of the vehicle, so as to ensure that the driving motor operates in a high-efficiency range and battery life.

no. 3 example

[0058] This embodiment also provides a vehicle, including the transmission described in the second embodiment above, so that the vehicle can switch gears according to its own driving speed, ensure that the drive motor operates in a high-efficiency range, and increase the cruising range of the vehicle.

[0059] At the same time, in the process of upshifting, downshifting and overtaking, the auxiliary power can be input by the second drive motor to ensure that the vehicle is always in a state of no power interruption during the driving process, improving the driving experience, especially overcoming high-speed overtaking When the vehicle speed is ≥ 80km / h, it can still provide strong power to achieve fast overtaking and improve driving safety.

[0060] To sum up, the embodiment of the present invention provides a transmission power transmission system, a transmission and a vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com