Multi-frequency sound absorption type acoustic superstructure

A super-structure, sound-absorbing technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of weak energy dissipation, limited use range and application scenarios, and occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

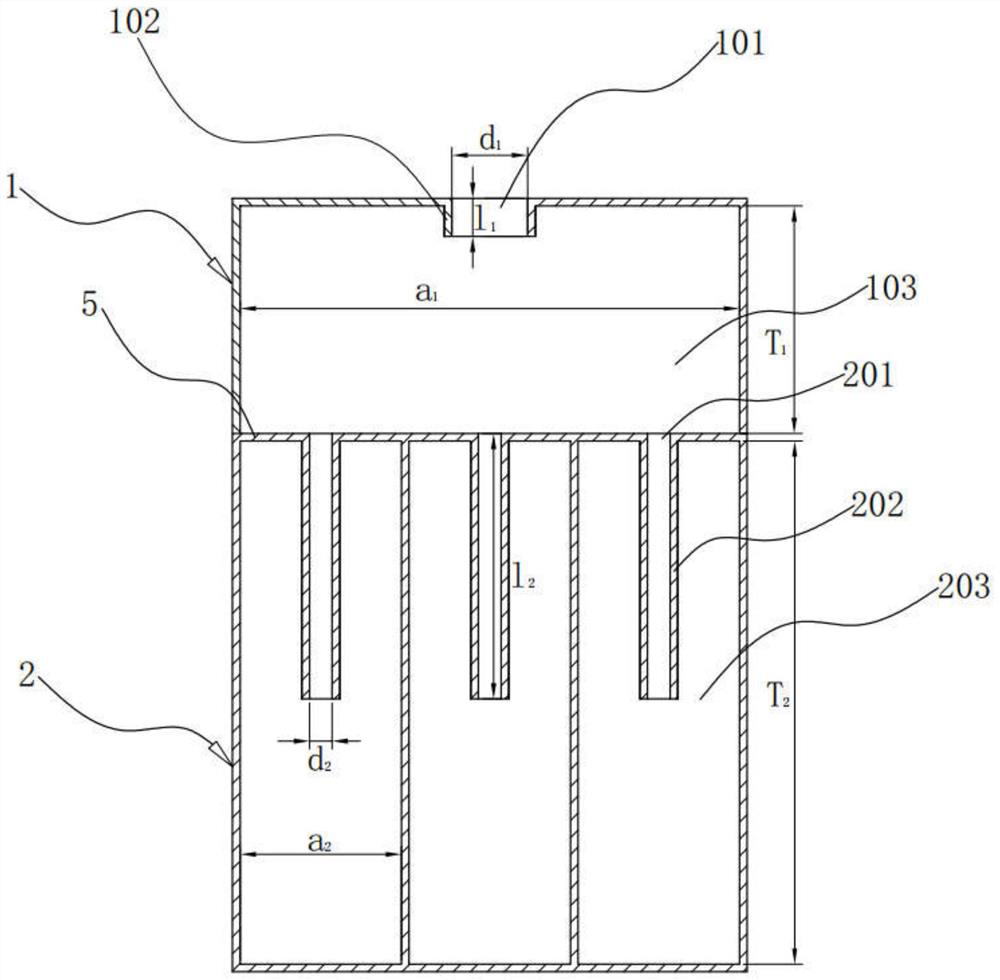

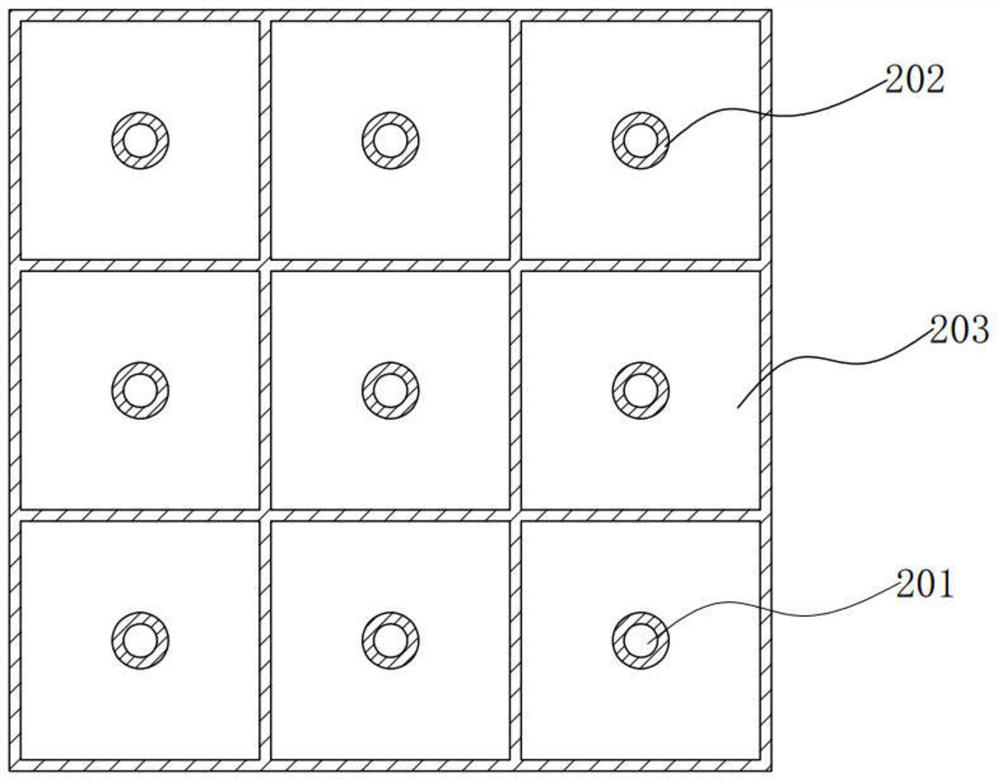

[0039] Refer figure 1 with figure 2 The multi-frequency sound absorbing type acoustic super structure of the present embodiment includes two sound absorbing units, respectively, respectively, respectively, respectively, and the first sound absorbing unit 1 and the second sound absorbing unit 2. In the manufacture of photosensitive resin materials, in this embodiment, the first sound absorbing unit 1 and the second sound absorbing unit 2 employ a rectangular square structure in which the cross section is a square structure, and a section is provided in the first sounding unit 1. The cavity 103 is further provided with a first opening 101 on the first sounding unit 1, and the first opening 101 is coupled to the first cavity 103, and there is a first tube on the first opening 101. 102. The first tube 102 is a structure integrally formed with the first opening 101, and the first tube 102 extends into the first cavity 103, one side opposite the first cavity 103 and the first opening 10...

Embodiment 2

[0058] The multi-frequency sound absorbing acoustic super structure of this embodiment employs three absorbing units such that sound absorption noise is performed for noise having three low frequency.

[0059] Refer Figure 5 with Figure 6 The multi-frequency sound absorbing acoustic hyperplashes of the present embodiment include the first sounding unit 1, the third sound absorbing unit 3, and the fourth suction unit 4, the first sound absorbing unit 1, the third sound absorbing unit 3 and the fourth The sound absorbing unit 4 is made of photosensitive resin material.

[0060] Refer Figure 5 with Figure 6 In the present embodiment, the first sound absorbing unit 1, the third sound absorbing unit 3, and the fourth suction unit 4 employ a rectangular square structure having a square cross section, and a cross section is square in the first sound absorbing unit 1. A cavity 103, further provided with a first opening 101 on the first sounding unit 1, and the first opening 101 is coupled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com