A kind of sound-absorbing and noise-reducing interior decoration material and preparation method thereof

A technology for interior decoration and raw materials, applied in the field of decorative materials, can solve the problems of low impact resistance, short service life, unfavorable promotion of polyvinyl chloride resin keels, etc., to improve impact resistance, enhance dissipation, and improve sound absorption and noise reduction effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

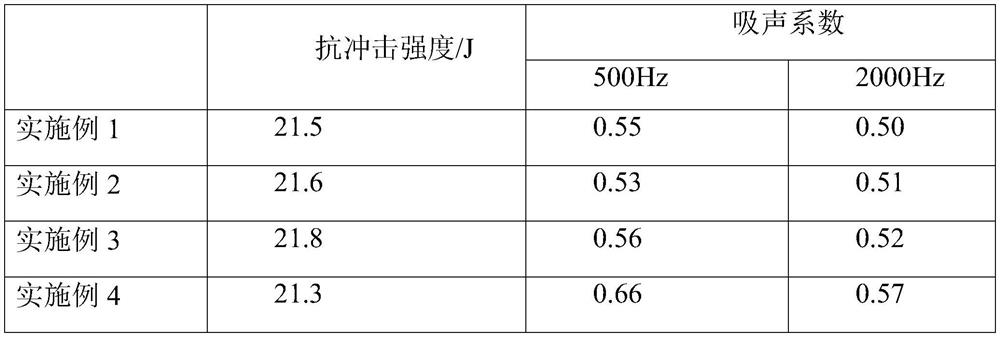

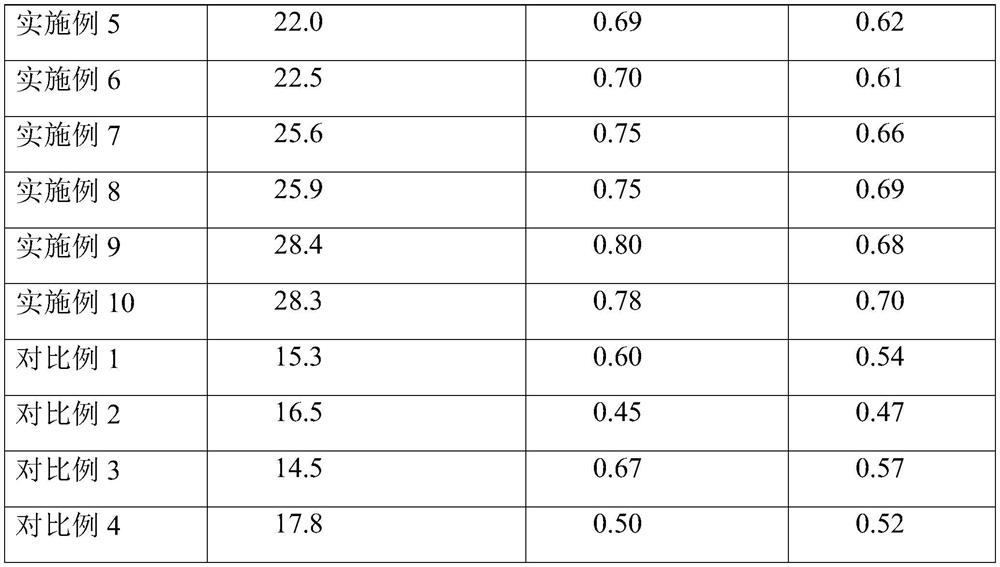

Examples

preparation example 1

[0048] Preparation of modified liquid:

[0049] At room temperature, mix and stir 0.1kg of γ-aminopropyltriethoxysilane, 0.1kg of hexamethyldisiloxane, 0.06kg of water-based polyurethane, 1kg of water and 0.15kg of ethanol in a reaction flask for 1.5 hours to obtain modifier fluid.

preparation example 2

[0051] Preparation of modified liquid:

[0052] At room temperature, mix and stir 0.1kg of γ-aminopropyltriethoxysilane, 0.15kg of hexamethyldisiloxane, 0.1kg of water-based polyurethane, 0.9kg of water and 0.1kg of ethanol in a reaction flask for 1.5 hours. Obtain modified solution.

Embodiment 1

[0055] A preparation method of a sound-absorbing and noise-reducing interior decoration material:

[0056] S1. under room temperature, 3kg polyvinyl chloride resin, 0.7kg styrene-methylstyrene copolymer, 0.13kg dilauryl thiodipropionate, 0.6kg tributyl citrate, 0.1kg calcium stearate and 0.05kg epoxidized soybean oil is dropped into the mixer, mixed and stirred for 20min, then added 0.2kg polycrystalline mullite fiber and continued to stir for 10min to obtain a mixture;

[0057] S2. put the mixture into the mill for milling, the milling temperature is 135°C, the milling time is 15min, and milled flakes are obtained;

[0058] S3. Put the refined flakes into the mould, then put the mold into a flat vulcanizing machine, vulcanize and form, molding temperature 150°C, molding time 10min, molding pressure 2Mpa, to obtain a sound-absorbing and noise-reducing interior decoration material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com