Broadband sound absorbing material and sound absorbing device

A technology of sound-absorbing device and sound-absorbing material, which is applied to shaft equipment, shaft lining, tunnel lining, etc., can solve problems such as the inability to meet the multiple requirements of sound-absorbing materials for expressway tunnels, the sound absorption coefficient is not high enough, and the manufacturing process is complicated. , to achieve the effect of increasing the effective area of sound absorption, increasing the sound absorption coefficient, and broadening the sound absorption frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

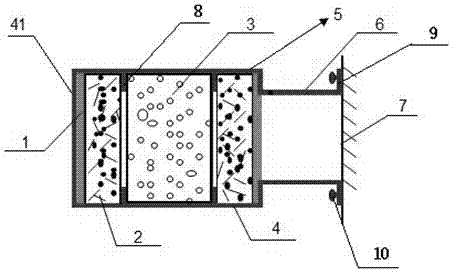

[0019] Such as figure 1 As shown, the broadband sound-absorbing material of the present invention includes an activated carbon fiber three-dimensional fabric layer 2 and a porous material layer 3; the activated carbon fiber three-dimensional fabric layer 2 is two layers, and the outer surface of each layer of activated carbon fiber three-dimensional fabric layer 2 is coated with nanofibers Film 1. The porous material layer 3 is arranged between the two activated carbon fiber three-dimensional fabric layers 2 . The porous material layer 3 adopts aluminum foam.

[0020] The thickness of the nanofiber membrane 1 is 10 μm, the thickness of the activated carbon fiber three-dimensional fabric layer 2 is 1 mm, and the thickness of the porous material layer 2 is 1 mm.

[0021] The sound-absorbing device of the present invention adopts the above-mentioned sound-absorbing material, including the connecting piece 5 . The connecting piece 5 is integrally formed by a steel plate, the fr...

Embodiment 2

[0024] The material and structure of each layer of the broadband sound-absorbing material of the present invention are the same as those in Embodiment 1. Wherein, the thickness of the nanofiber membrane 1 is 100 μm, the thickness of the activated carbon fiber three-dimensional fabric layer 2 is 4 mm, and the thickness of the porous material layer 2 is 6 mm.

[0025] The structure of the sound-absorbing device of the present invention is the same as that of Embodiment 1. Wherein the depth of the cavity 6 is 40 mm.

[0026] The sound absorption device is tested, and the average sound absorption coefficient in the 80-6300 Hz frequency band is 0.82, and the maximum value is 0.98.

Embodiment 3

[0028] The material and structure of each layer of the broadband sound-absorbing material of the present invention are the same as those in Embodiment 1. Wherein, the thickness of the nanofiber membrane 1 is 1000 μm, the thickness of the activated carbon fiber three-dimensional fabric layer 2 is 10 mm, and the thickness of the porous material layer 2 is 10 mm.

[0029] The structure of the sound-absorbing device of the present invention is the same as that of Embodiment 1. The depth of the cavity 6 is 100 mm.

[0030] The sound absorption device is tested, and the average sound absorption coefficient in the 80-6300 Hz frequency band is 0.70, and the maximum value is 0.97.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com