Micropterus salmoides culture sewage treatment equipment

A technology for cultivating sewage and largemouth bass, which is applied to the feeding/discharging devices, chemical instruments and methods, separation methods, etc. Mud efficiency, easy to use and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

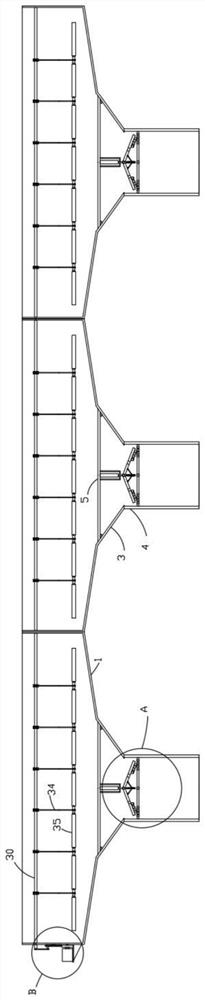

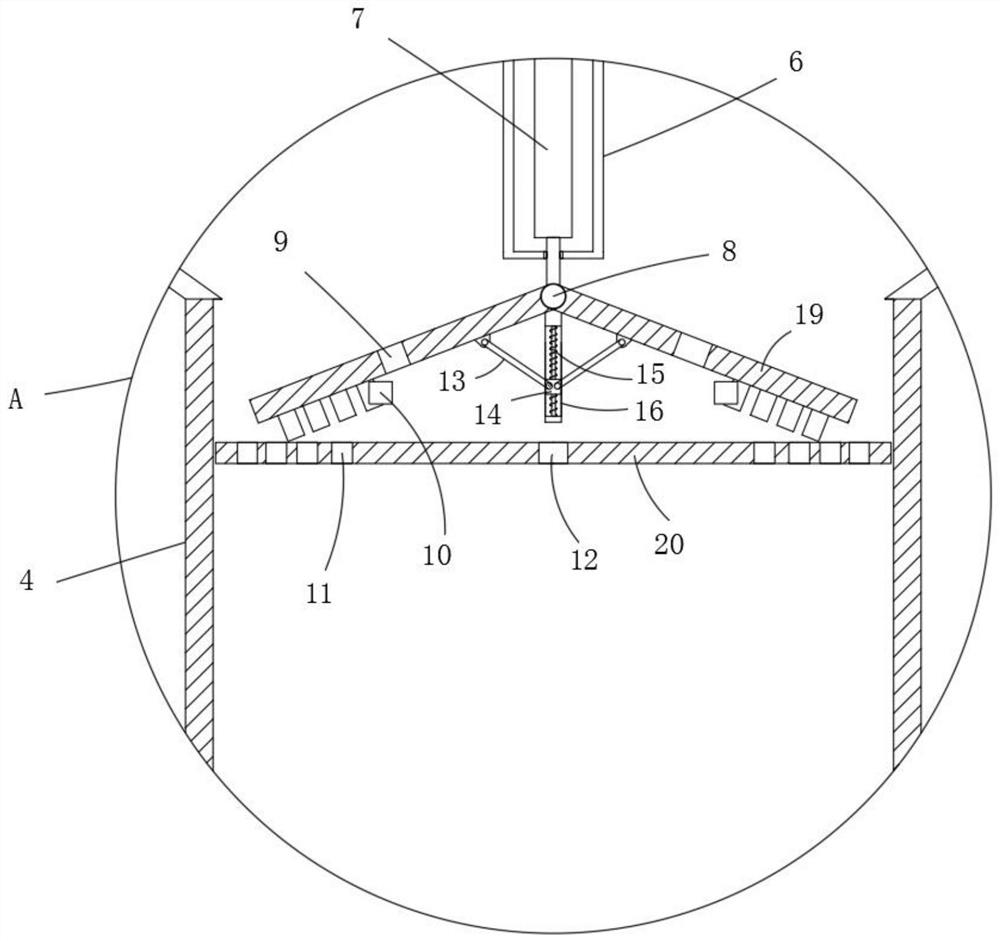

[0032] See Figure 1-5 , Large mouthful breeding sewage treatment equipment, including a plurality of interconnected precipitation tanks, each having at least one gathering struggle for aggregating sludge 3, the bottom end of the gathering strip 3 Fixed tube 4. The sewage is stored in the sedimentation tank 1, and the sewage is precipitated in the precipitated tank 1, and the precipitated sludge enters the tube 4 in the lower end of the aggregate.

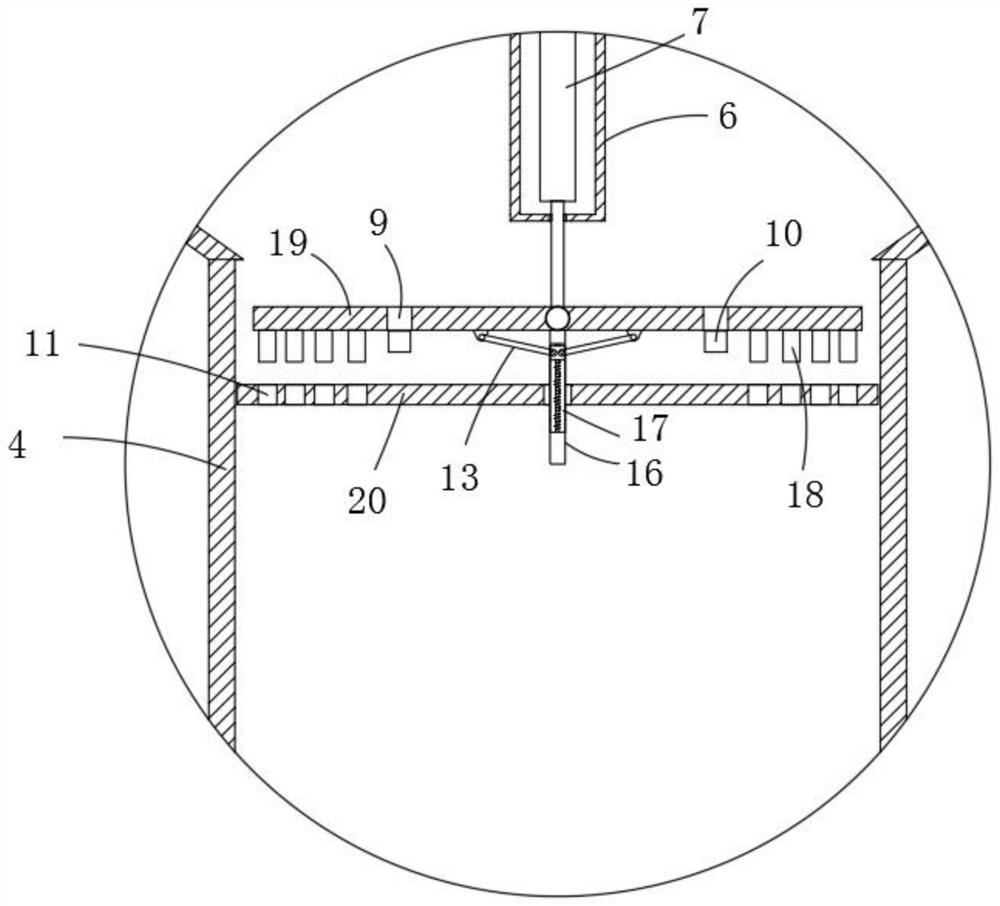

[0033] Please refer to figure 2 , 3 4, the mud tube 4 is slidably connected to a movable plate 20, and a plurality of through holes 11 are opened on the movable plate 20, and a central hole 12 is also opened at the center of the movable plate 20.

[0034] Please refer to figure 2 , 3 4, the tube 4 located above the movable plate 20 is also provided with a blocking mechanism to open the through hole 11 on the movable plate 20.

[0035] Please refer to figure 2 , 3 4, and the plug-in mechanism contains the shaft 8 and the two pieces rotat...

Embodiment 2

[0044] See figure 1 as well as Figure 6 , Figure 7 In the present embodiment, as further improvements of Example 1, a aerating mechanism is also provided in the precipitation tank, the aeration mechanism including a rotating rod 30 that is horizontally coupled to the side wall of the precipitation tank, located in the precipitated tank. 1 The aeration pipe 35 at the bottom, the exposure pipe 35 and the rotating rod 30 are connected by a plurality of strand cables 34, and both ends of the cable 34 are respectively connected to the aeration pipe 35, and the rotating rod 30, respectively. The agencies also include power components for driving the rotating rod 30 reciprocating rotation.

[0045] As a further improvement of the above scheme, the power assembly includes a turntable 29, a connecting rod 31, a motor 32, a gear 33, and the turntable 29 are rotatably coupled to the outer wall of the precipitation tank 1, and the side surface of the turntable 29 is fixed, the motor 32 is mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com