Production method of heavy calcium carbonate

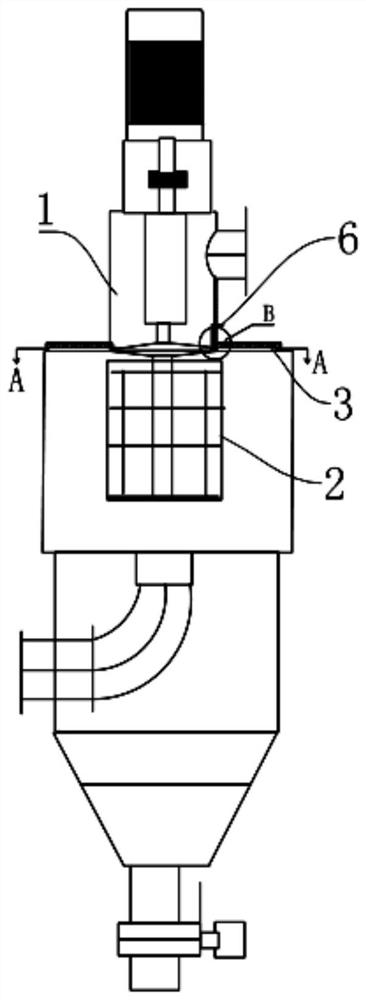

A technology of heavy calcium carbonate and production method, applied in the directions of climate sustainability, sorting, sustainable manufacturing/processing, etc., can solve problems such as large environmental pollution, pollute the environment, reduce the quality of heavy calcium, and avoid coarse particles. The effect of reducing the generation of coarse particles and solving the dust problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

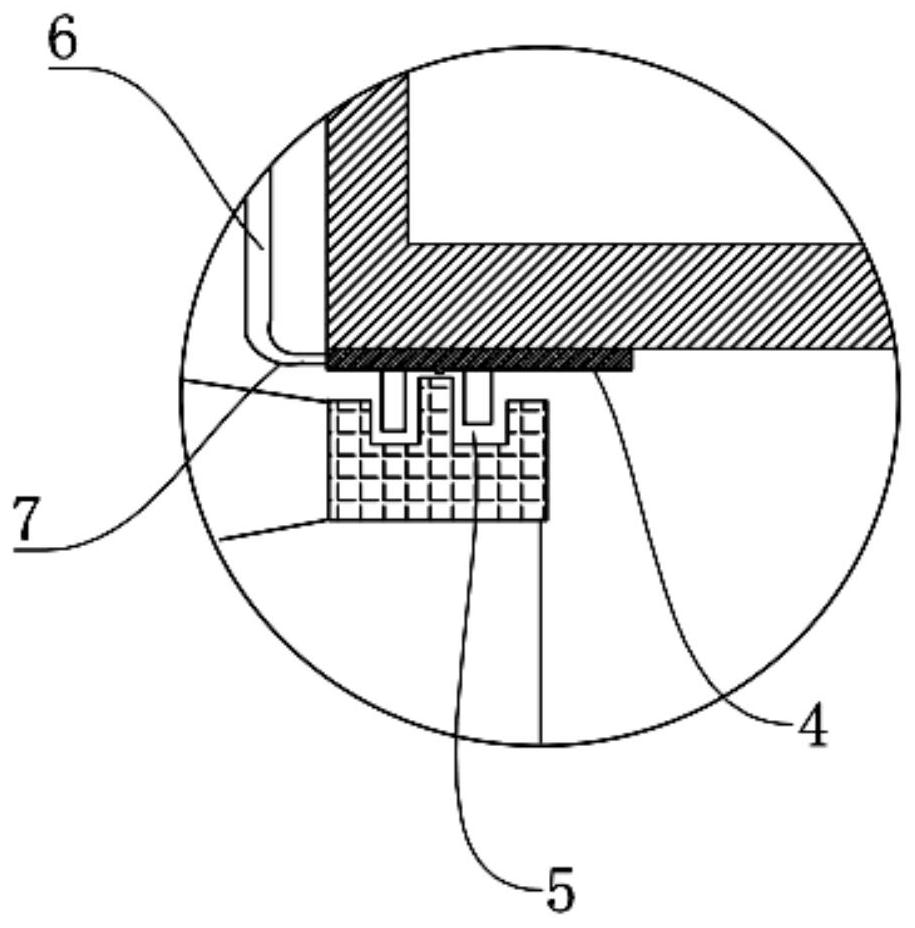

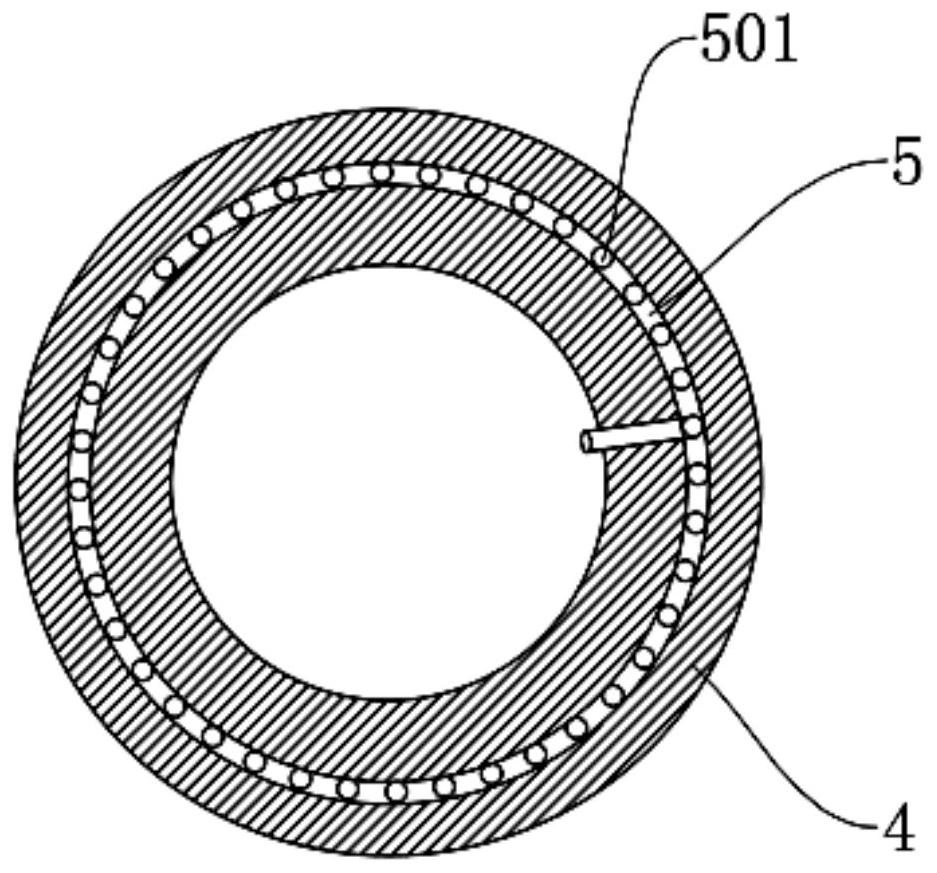

[0029] A kind of production method of heavy calcium carbonate, in grinding process,

[0030] The specific start-up sequence is: first turn on the classifier, speed up to 200 rpm, then turn on the fan, speed up to 200 rpm, and finally turn on the host, speed up to 200 rpm; then the classifier speed up to 400 rpm, and the fan speed up to 400 Turn, the main engine speeds up to 400 rpm; that is, increase the speed alternately by 200 rpm each time until it reaches the constant speed.

[0031] The specific shutdown sequence is: firstly reduce the speed of the main machine by 200 rpm, then reduce the speed of the fan by 200 rpm, and finally reduce the speed of the classifier by 200 rpm; that is, reduce the speed alternately by 200 rpm each time until it stops.

Embodiment 2

[0033] A kind of production method of heavy calcium carbonate, setting constant speed rotation number is 1500 revs.

[0034] In the grinding process, the specific start-up sequence is: turn on the classifier, increase the speed to 100 rpm → turn on the fan, increase the speed to 100 rpm → open the fan inlet valve → turn on the main engine, increase the speed to 100 rpm → turn on the return elevator → turn on Return material auger → open feeding auger → open agitating auger → open feed rotary valve → open drug pump → classifier speed up to 200 rpm → fan speed up to 200 rpm → host speed up to 200 rpm → classifier Speed up to 300 RPM → fan speed up to 300 RPM → host speed up to 300 bricks, that is, increase the speed alternately by 100 revolutions each time until it reaches the constant speed of 1500 revolutions.

[0035] The shutdown sequence is: turn off the drug pump → turn off the feed rotary valve → turn off the stirring auger → turn off the feeding auger → turn off the re...

Embodiment 3

[0037] A kind of production method of heavy calcium carbonate, setting constant speed rotation number is 1500 revs.

[0038] In the grinding process, the specific start-up sequence is: turn on the classifier, increase the speed to 200 rpm → turn on the fan, increase the speed to 200 rpm → open the fan inlet valve → turn on the main engine, increase the speed to 200 rpm → turn on the return elevator → turn on Return material auger → open feeding auger → open mixing auger → open feeding rotary valve → open drug pump → classifier speed up to 400 rpm → fan speed up to 200 rpm → host speed up to 400 rpm → classifier Speed up to 600 rpm → fan speed up to 600 rpm → host speed up to 600 bricks, that is, increase the speed alternately by 200 rpm each time until it reaches the constant speed of 1500 rpm.

[0039]The shutdown sequence is: turn off the drug pump → turn off the feed rotary valve → turn off the stirring auger → turn off the feeding auger → turn off the return auger → turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com