Wind power blade lightning arrester mounting device and mounting method

A technology for wind power blades and installation devices, which is applied in the field of installation devices for wind power blade lightning receptors. It can solve problems such as inability to accurately drill holes vertically to the base, and achieve the effects of avoiding electric field distortion and preventing water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

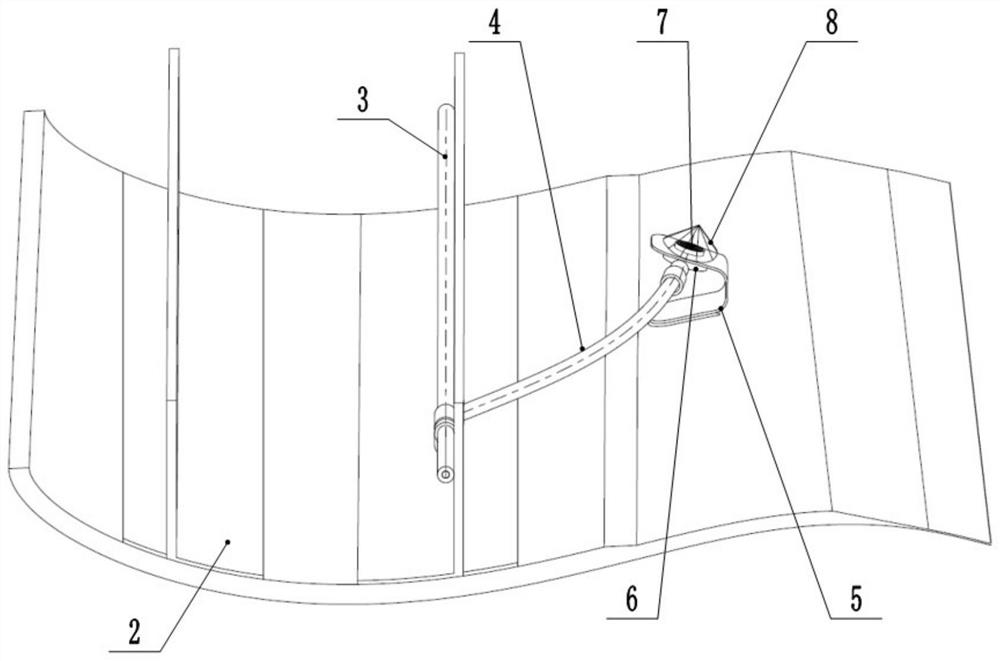

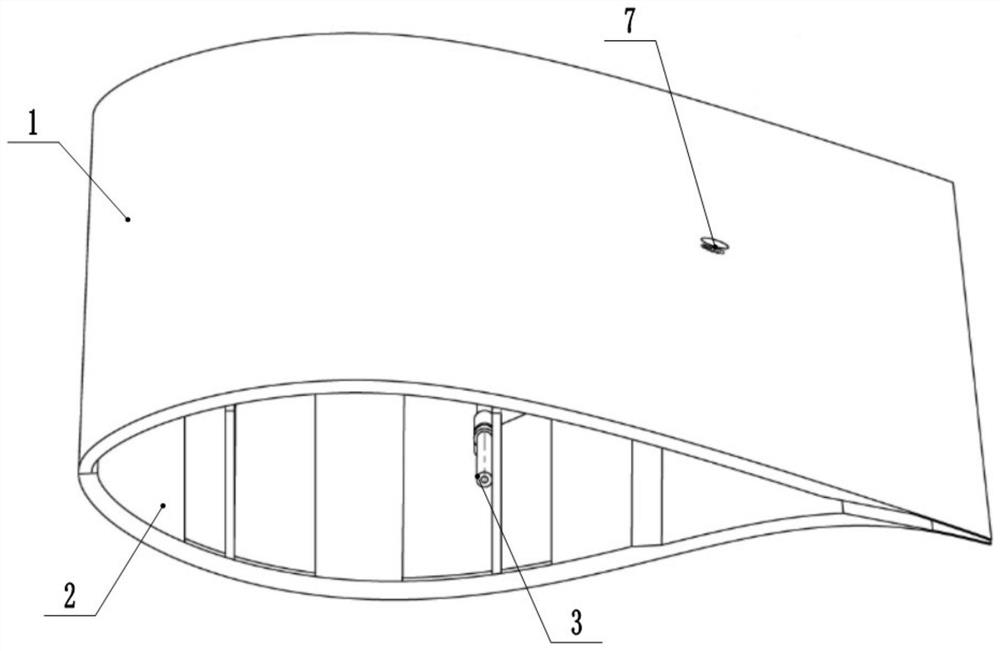

[0043] Basic as attached Figure 1-12 Shown: a wind power blade air-termination installation device, including the upper air-termination installation assembly and the lower air-termination installation assembly, the upper air-termination installation assembly installs the upper air-termination 14 on the upper housing 1 of the wind power blade; The air-termination installation assembly is used to install the lower air-termination device on the lower shell 2 of the wind turbine blade; the upper air-termination installation assembly includes a first positioning plug 7, an adhesive layer 8, a sealing layer, a C-shaped mounting pad 5, a guide Shaft 16, first hole opener 12 and second hole opener 13; C-type mounting pad 5 is an elastic pad, such as figure 1 , 6 , 7, one side of the C-type mounting pad 5 is fixed on the inner wall of the lower case 2, and the other side of the C-type mounting pad 5 is fixed on the base 6 of the lightning receptor 14. The base 6 of the upper air rec...

Embodiment 2

[0045] A method for installing a wind power blade lightning receptor, using the wind power blade lightning receptor installation device of Embodiment 1, comprising the following steps:

[0046] Step 1: Preparations before mold closing;

[0047] S1.1: Connect the base 6 of the upper air-termination device 14 to the sub-wire 4, tighten the first positioning plug 7 of the upper housing 1 on the base 6 of the upper air-termination device 14, and fix the C-shaped mounting pad 5 on the lower housing on the inner wall of the body 2; glue the base 6 of the upper lightning receptor 14 on the C-shaped mounting pad 5, and the first positioning plug 7 faces the inner wall of the upper housing 1; stick on the center hole 11 of the first positioning plug 7 One layer of sealing layer, an adhesive layer 8 is set around the base 6 and the first positioning plug 7 for wrapping, specifically, glue is accumulated on the base 6 and the first positioning plug 7, and the first positioning plug 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com