Optical precision machining unit

A processing unit and optical precision technology, applied in stone processing equipment, optical surface grinders, stone processing tools, etc., can solve the problems of processing efficiency decline, achieve high processing accuracy and ensure symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

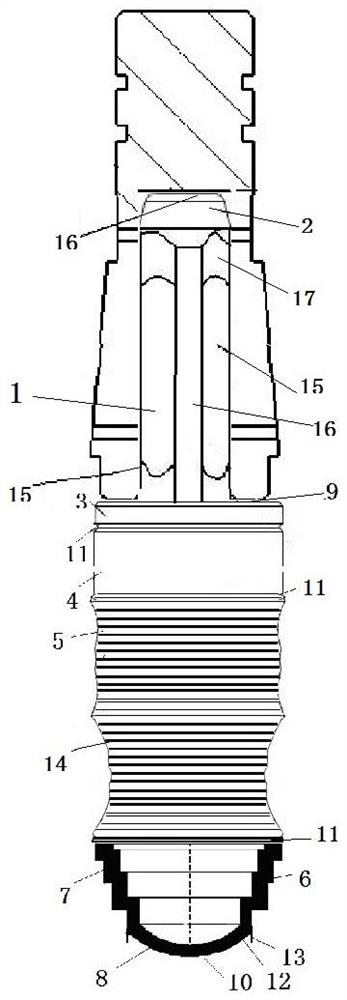

[0022] See attached figure 1 As shown, a kind of optical precision machining unit comprises a grinding tool holder, a grinding tool installed in the grinding tool fixing clamp hole 15 of the grinding tool base, and a control unit. The grinding tool base has a grinding tool fixing clamp hole 15, and the grinding tool is fixed The inner top of the clip hole 15 has a limiting surface 16 .

[0023] The grinding tool includes a handle 1, the upper end of the handle 1 has a tapered tool guide 2, the tool guide 2 is pressed against the limit surface 16 in the fixing clamp hole 15 of the grinding tool, the tool handle 1 includes a The plurality of first planes 15 made by extrusion molding method and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com