Cosmetic egg integrated grinding machine

A technology for grinding machines and make-up eggs, which is applied in the direction of grinding racks, grinding machine parts, grinding machines, etc. It can solve the problems of low production efficiency, inconvenient use, and long time consumption, so as to speed up work efficiency and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

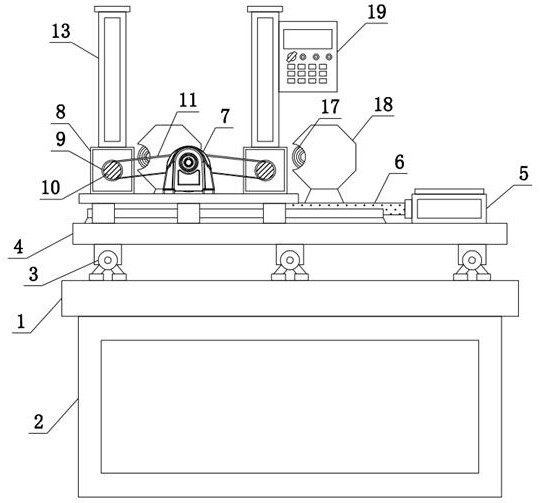

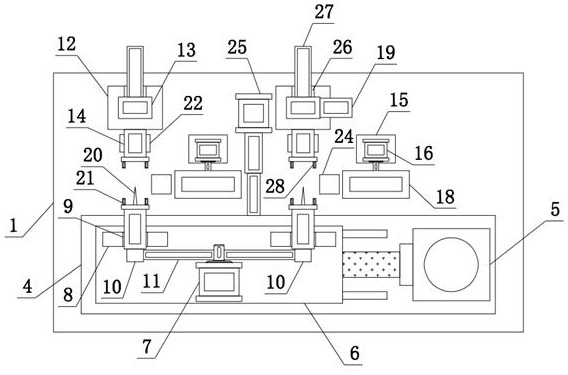

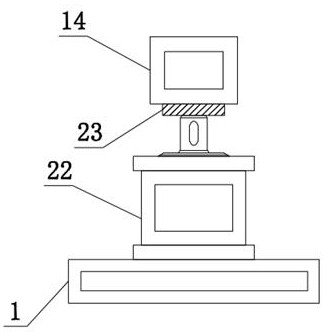

[0030] refer to Figure 1-3 , an integrated grinding machine for cosmetic eggs, comprising a workbench 1, a support box 2 is fixedly connected to the bottom of the workbench 1, and three sets of sliding sticks 3 are fixedly connected to the front end of the top of the workbench 1, and the sliding sticks 3 The top of the top is slidingly connected with a mounting frame 4, and the right side of the top of the mounting frame 4 is fixedly installed with a servo motor 5, and the output end of the servo motor 5 is fixedly mounted with a screw slide table 6, and the screw slide table 6 The middle end of the top is fixedly equipped with a rotary motor 7, and the top left and right sides of the screw mandrel slide 6 are fixedly connected with mounting plates 8, and the front of the mounting plate 8 is provided with mounting holes 9, and the mounting holes 9 The interior is fixedly connected with a rotating clamping head 10, the output end of the rotating motor 7 is sleeved with a belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com