Conjugated wheel antifriction mechanism for cam axle conjugated abrasive band grinding

A technology of abrasive belt grinding and conjugate wheel, which is applied in the direction of abrasive belt grinder, grinding/polishing equipment, grinding machine, etc., can solve the problems of conjugate wheel wear, high cost of conjugate wheel, affecting processing efficiency and precision, etc. Achieve the effect of reducing friction, improving service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

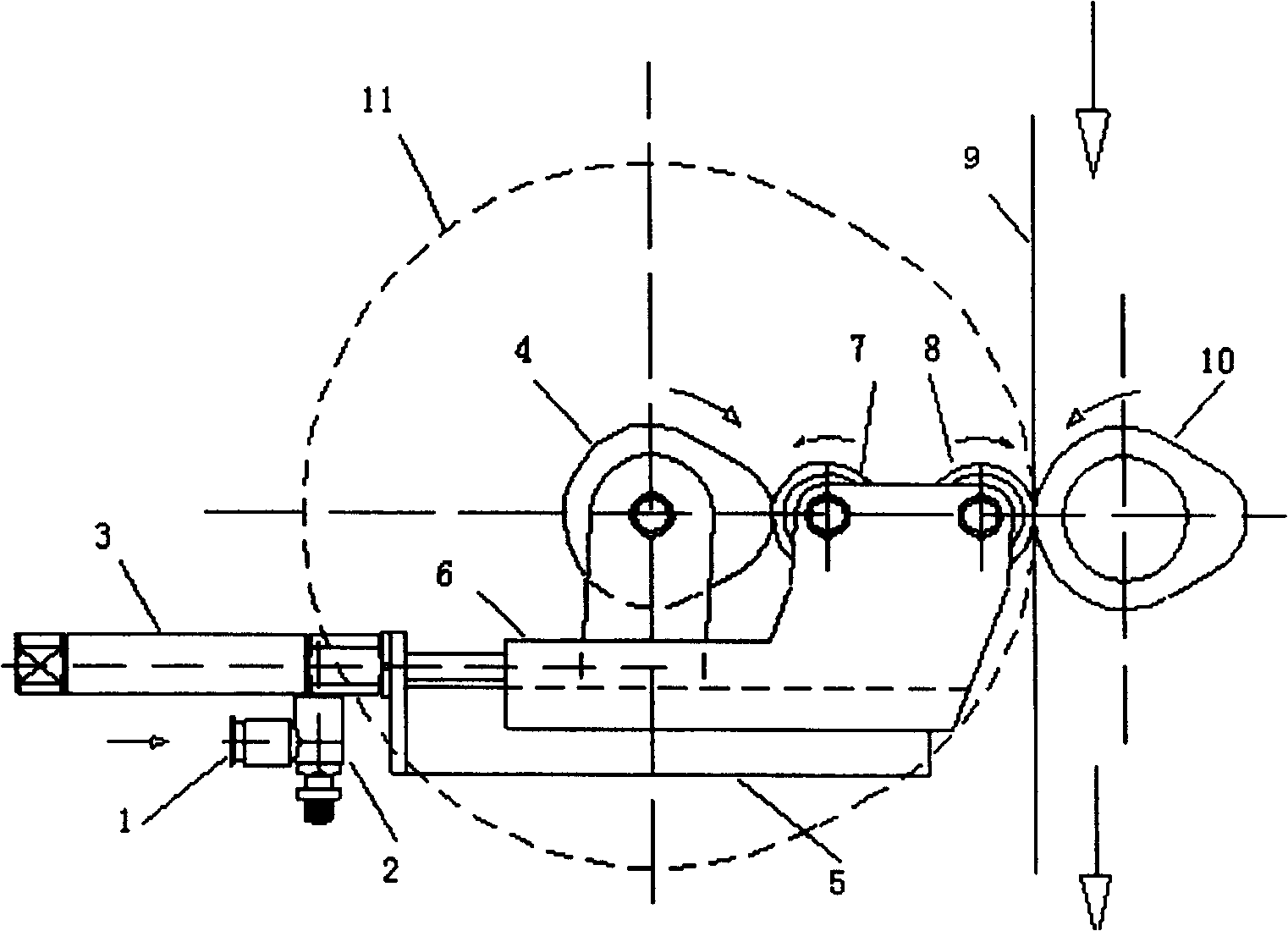

[0013] Such as figure 1 Shown is a schematic diagram of the structure of the present invention. The present invention includes: a clamping device, a fixed base 5 , a slide block 6 and a conjugate cam 4 . The slide block 6 is provided with two small round wheels 7, 8, and the whole slide block 6 is located in the guide rail in the fixed base 5, and the fixed base 5 is provided with a conjugate cam 4, wherein the small round wheel 8 on the right side is connected with the The opposite side of abrasive belt 9 is in contact, the small round wheel 7 on the left side is in contact with conjugate cam 4, and the tightening device is connected with slide block 6.

[0014] The tightening device in the present invention can be a cylinder device, also can be a hydraulic transmission device or a spring device, as long as the slide block is tightened against the abrasive belt, it all belongs to the scope of the present invention.

[0015] Refer below figure 1 Describe in detail the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com