Method for achieving high-speed cutting on center lathe and multifunctional machine head

A common lathe, high-speed cutting technology, applied to metal processing machinery parts, clamping, support, etc., can solve the problems of poor product quality, slow speed of common lathes, low processing accuracy, etc., to improve processing efficiency and quality, and save equipment The effect of purchasing cost and guaranteeing machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

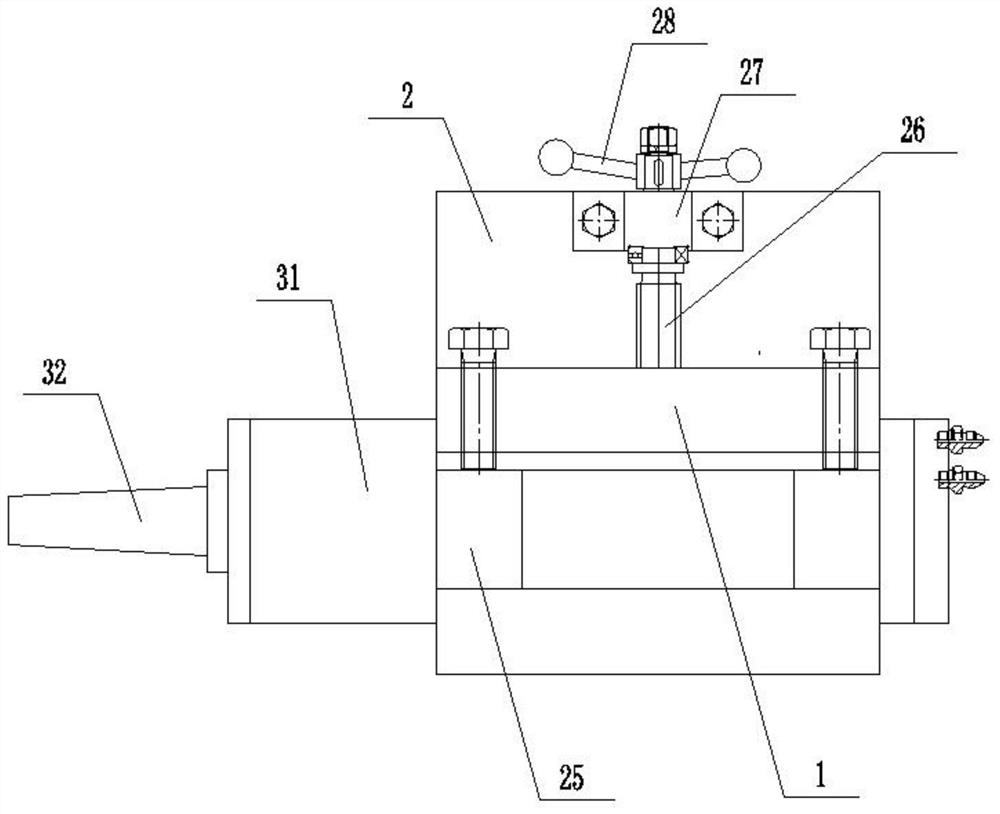

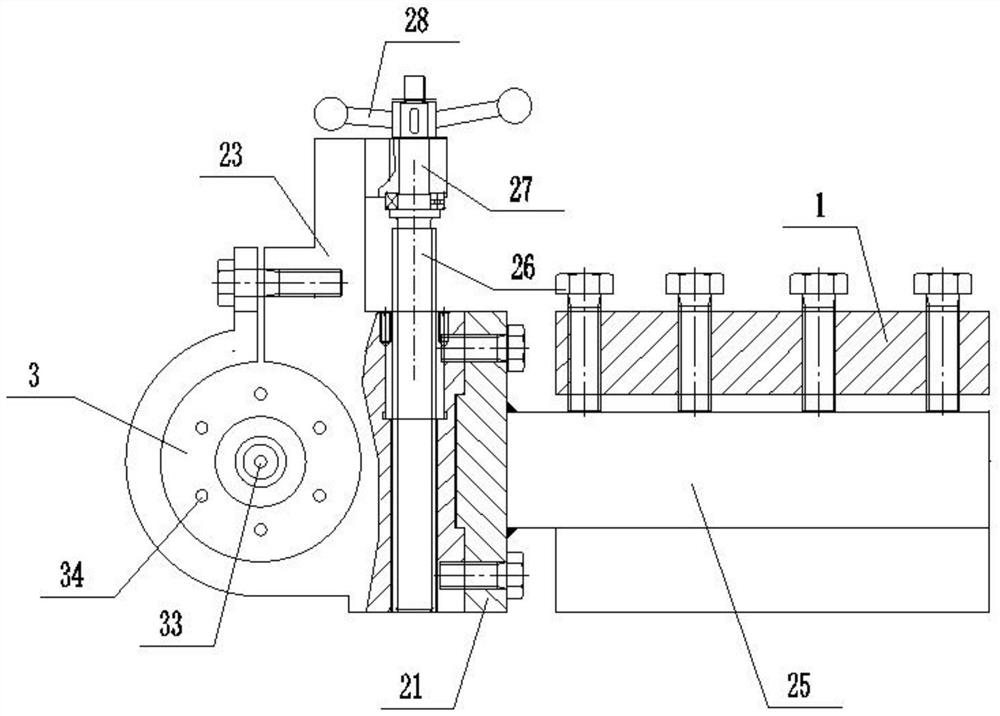

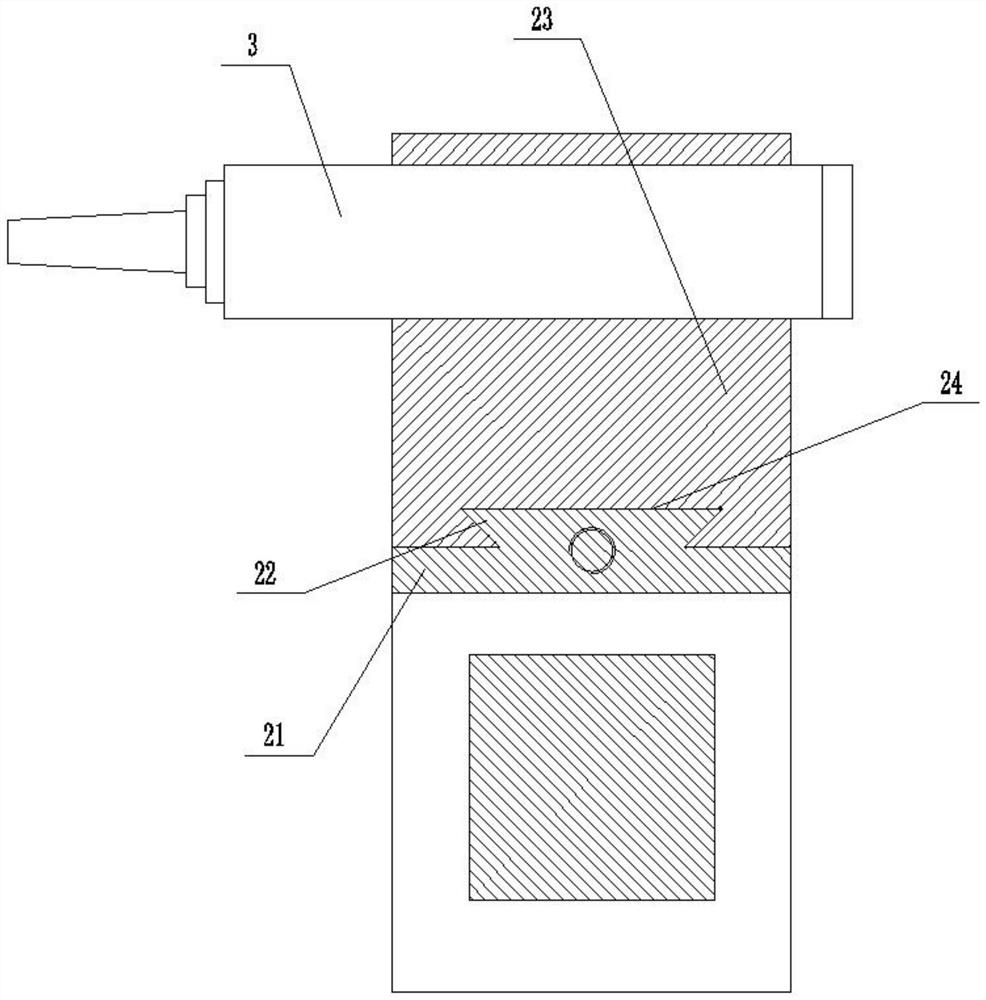

[0038] A multifunctional handpiece, such as Figure 1 ~ Figure 3 As shown, it includes a base 2 and an electric spindle 3 . The base 2 includes a first base 21 and a second base 23 , and the electric spindle 3 is installed on the second base 23 . The side of the first base 21 close to the second base 23 is provided with a slide block 22, the side of the second base 23 close to the first base 21 is provided with a slide groove 24, the slide block 22 is slidably arranged in the slide groove 24, and The chute 24 extends vertically, so that the slider 22 can slide vertically in the chute 24 . The cross sections of the chute 24 and the slider 22 are both dovetail-shaped, so that the slider 22 is clamped in the chute 24 to prevent the slider 22 from detaching from the opening of the chute 24 . The first base 21 is also provided with a fixed bracket 25 away from the side of the second base 23, and the fixed bracket 25 is fixed on the square tool rest 1 of the ordinary lathe by bolt...

Embodiment 2

[0047] A high-speed grinding head, such as Figure 4 As shown, it includes the multifunctional machine head of Embodiment 1, and also includes a grinding tool. The grinding tool includes a grinding wheel cover 41 , a grinding wheel 43 , a grinding wheel outer baffle 44 and a first nut 45 . The grinding wheel cover 41 is sleeved on the rotating shaft 32 of the electric spindle 3 , and the slope of the inner wall of the grinding wheel cover 41 matches the slope of the side wall of the rotating shaft 32 , limiting the insertion distance of the grinding wheel cover 41 on the rotating shaft 32 . The grinding wheel 43 and the grinding wheel outer baffle 44 are sleeved on the grinding wheel cover 41, and the end of the grinding wheel cover 41 close to the housing 31 of the electric spindle 3 is integrally provided with the grinding wheel inner baffle 32, and the grinding wheel outer baffle 44 is located in the grinding wheel 43 away from the grinding wheel. One side of the baffle 42...

Embodiment 3

[0050] A high-speed inner hole grinding machine head, such as Figure 5 As shown, it includes the multifunctional head of Embodiment 1, and also includes a long rod sleeve device and an inner hole grinding tool.

[0051] The long rod sleeve device includes a transmission long shaft 51 and a sleeve 52 . One end of the long transmission shaft 51 is screwed into the threaded hole 33 at the end of the rotating shaft 32 . The sleeve 52 is sheathed outside the long drive shaft 51 , and one end of the sleeve 52 is fixed to the mounting hole 34 at the end of the housing 31 by a bolt, and an abutting groove 58 is provided on the outer wall of the other end of the sleeve. The rotating shaft 32 can drive the transmission long rod 51 to rotate, and the long rod sleeve device plays the role of extending the rotating shaft 32 .

[0052] The long drive shaft 51 is also sleeved with a lock nut 53 and an inner retaining ring 55, each of the two ends of the inner retaining ring 55 is closely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com