Crossing type traction and insertion combining device for U-shaped pipe of cooling tower

A combined device and U-shaped tube technology, which is applied in the field of cooling towers, can solve problems such as tube plate misalignment, low U-shaped tube assembly efficiency, and U-shaped tube misalignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

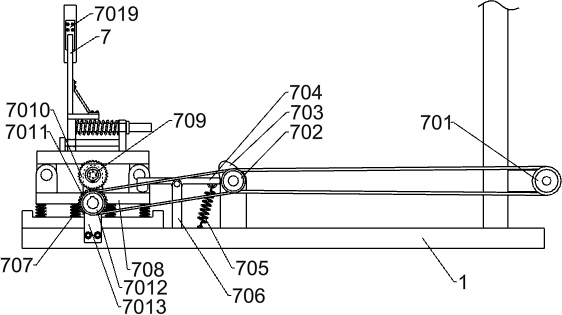

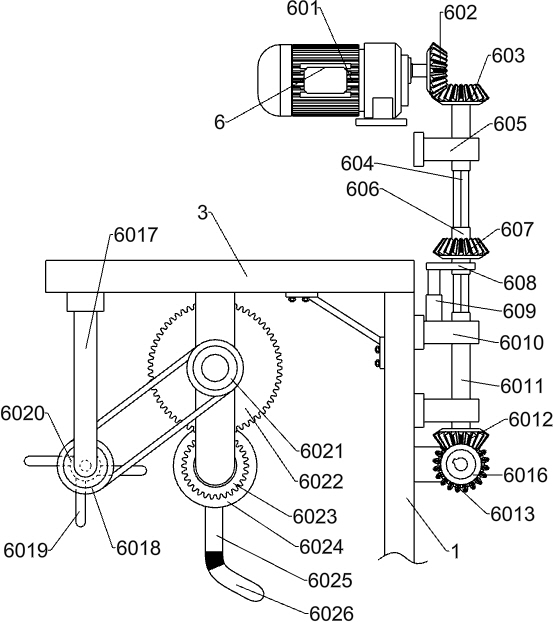

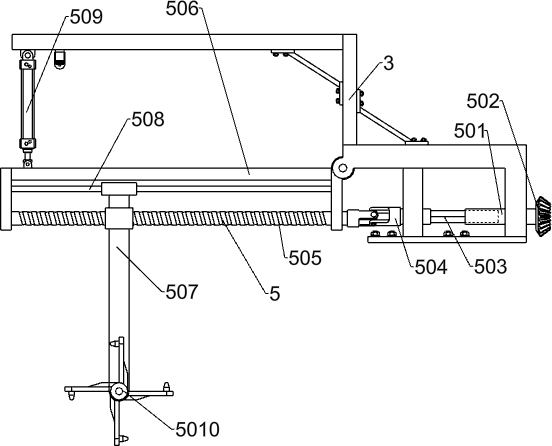

[0095] A cooling tower U-shaped pipe spanning type pulling combination device, such as Figure 1-9 As shown, it includes a body frame 1, a wheel 2, a top mounting frame 3, a push handle bar frame 4, a traction alignment system 5, an auxiliary propulsion system 6, a first fixed alignment system 7 and a second fixed alignment system 8 ; The top of the wheel 2 is bolted to the body frame 1; the bottom of the top mounting frame 3 is bolted to the body frame 1; Push the handlebar frame 4 to weld with the body frame 1; The auxiliary propulsion system 6 is connected with the top mounting frame 3, the auxiliary propulsion system 6 is connected with the vehicle body frame 1, and the auxiliary propulsion system 6 is connected with the traction alignment system 5; the first fixed alignment system 7 is connected with the vehicle body The frame 1 is connected, the first fixed positioning system 7 is connected with the auxiliary propulsion system 6; the second fixed positioning system 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com