A device and method for self-assembly of micro-devices based on micro-vibration excitation

A self-assembly, micro-device technology, applied in microstructure devices, manufacturing microstructure devices, measurement devices, etc., can solve the problems of weakening the positioning accuracy of micro-components and substrates, low assembly efficiency, etc., to solve the problem of low assembly efficiency and improve assembly. success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

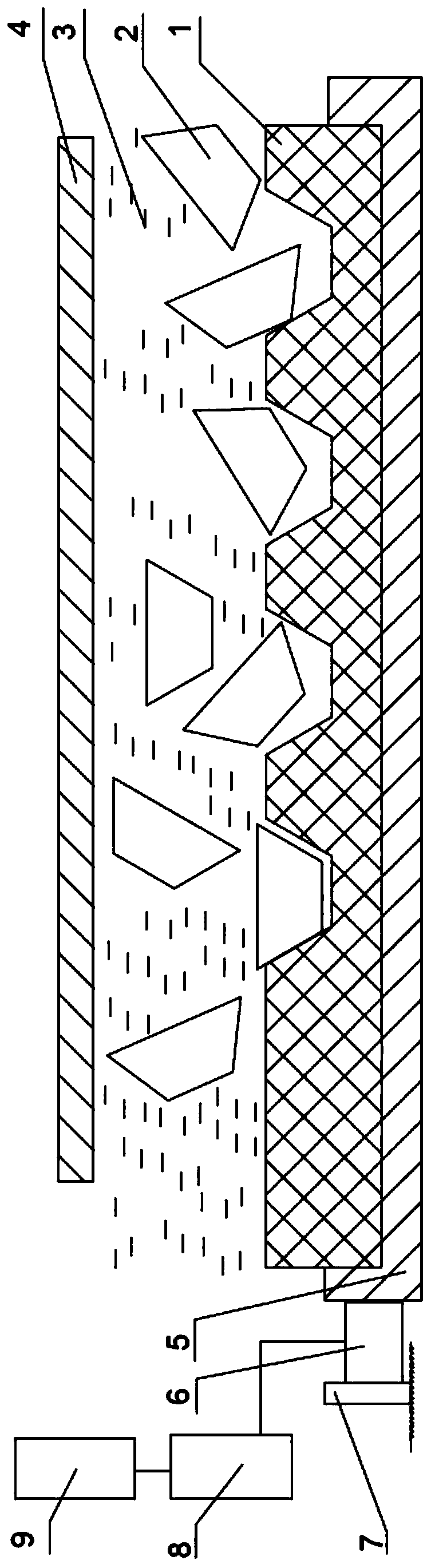

[0014] This embodiment provides a self-assembly device based on micro-vibration excitation micro-device, the structure is as follows figure 1 Shown:

[0015] On the substrate 1 such as silicon or glass, there is an array of pits of corresponding shapes etched out, each pit is matched with a micro-element 2 of a specific shape manufactured from a silicon wafer, and the micro-element 2 is carried by a carrier solution 3, The partition plate 4 and the substrate 1 form an assembly cavity, and the substrate 1 such as silicon or glass is rigidly connected to one end of the piezoelectric stack driver 6 through a rigid connecting plate 5, and the other end of the piezoelectric stack driver 6 is fixed on the fixed support 7 , the piezoelectric stack driver is controlled by a computer 9 and a driving power supply 8 .

Embodiment 2

[0017] This embodiment provides a self-assembly method based on the self-assembly device described in Embodiment 1.

[0018] The excess microelements 2 are dispersed and suspended in the selected carrier solution 3, and can flow through the substrate 1 and the separator 4 under pressure, and the computer 9 is programmed to control the piezoelectric stack driver 6 through the driving power supply 8 to fix the The support 7 supports lateral vibration, and the computer 9 is programmed to control the amplitude, frequency and acceleration of the piezoelectric stack driver 6 through the drive power supply 8 .

[0019] When the carrier solution 3 suspends an excessive amount of micro-elements 2 and flows through the array of pits on the substrate 1, the micro-elements, the capillary force and surface tension of the liquid bonding material will randomly fall into the matching pits on the substrate , some of the micro components 2 are completely fitted into the pits of the substrate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com