Concentrated ink supply system for printing ink

A printing ink and ink supply technology, which is applied in the field of paper product printing, can solve problems such as insufficient ink supply pressure and low printing effect of printing equipment, and achieve the effects of improving printing effect, reducing waste, and saving ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses a centralized ink supply system for printing ink.

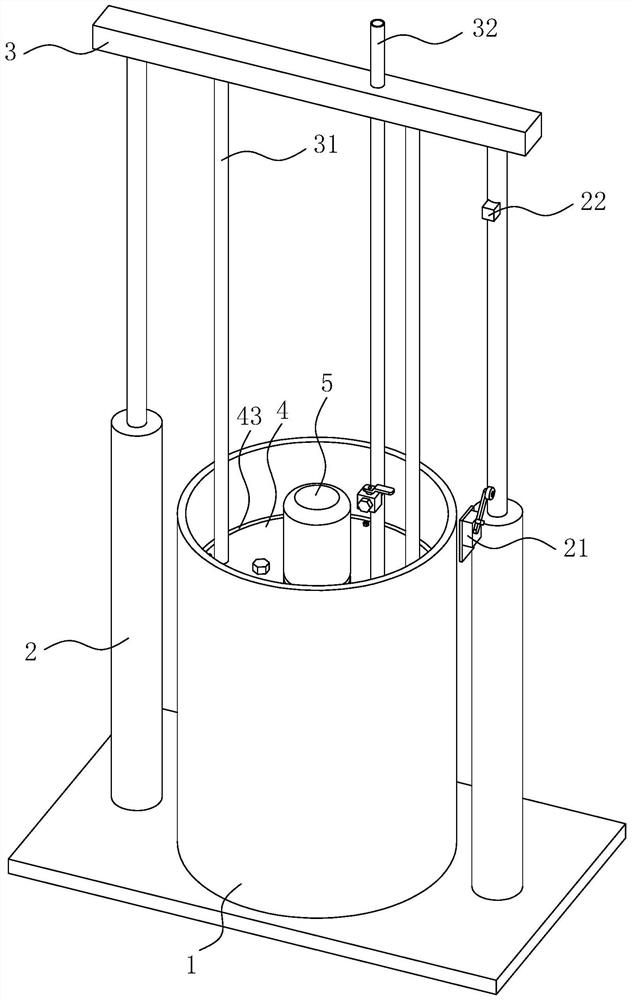

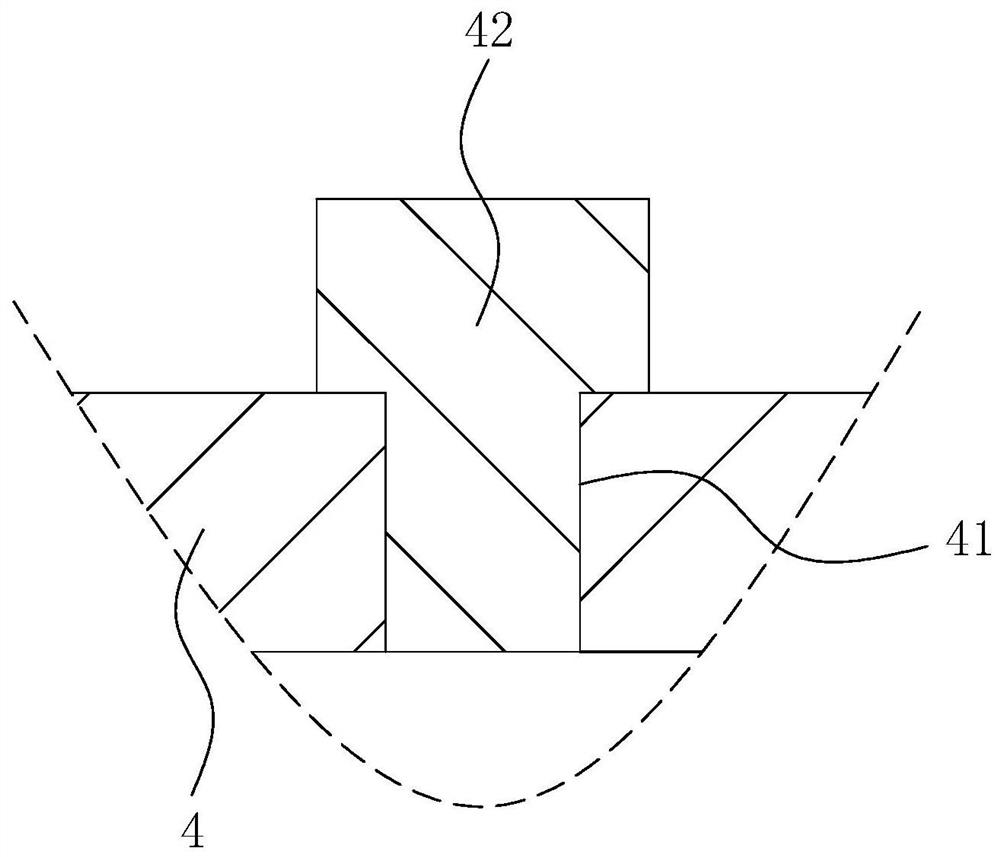

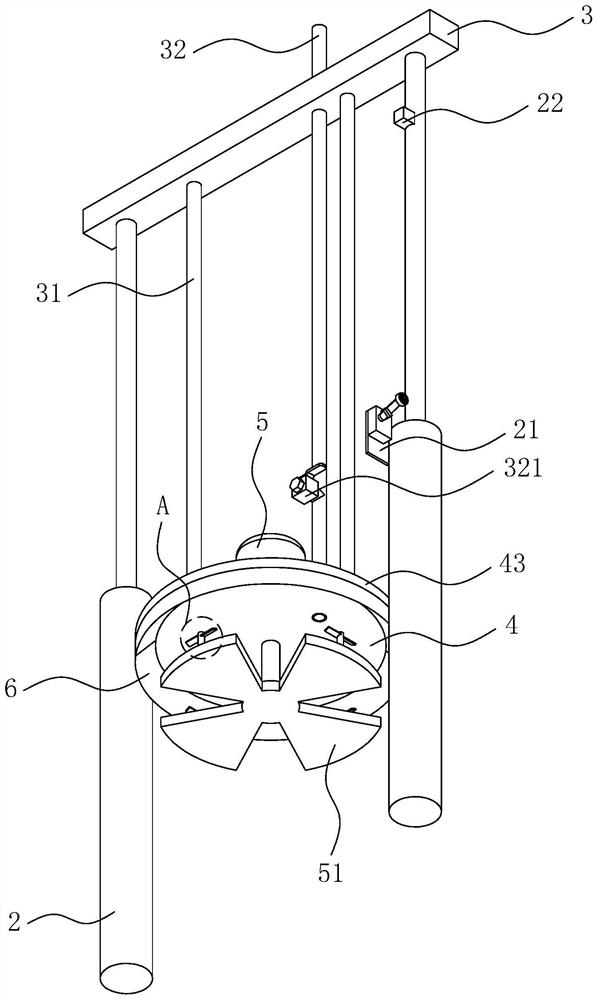

[0041] refer to figure 1 with figure 2 A centralized ink supply system for printing ink includes an ink tank 1 that is vertically arranged and has an upper opening. Both sides of the ink tank 1 are vertically provided with a lifting device 2 fixed to the ground. The lifting device 2 is a hydraulic cylinder or an air cylinder. The tops of the two lifting devices 2 are fixed with a horizontal top plate 3, the lower surface of the top plate 3 is vertically fixed with two connecting rods 31 extending into the ink tank 1, and the bottom ends of the two connecting rods 31 are horizontally fixed with a piston plate 4 , the circumferential side wall of the piston plate 4 is fixed with a rubber ring 43, and the rubber ring 43 is squeezed between the 4 circumferential side walls o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com