Integral type vehicle door vertical handrail and mounting structure thereof

An installation structure, integrated technology, applied in the field of auto parts, can solve the problems of many matching parts, poor maintainability, low efficiency, etc., to achieve the effect of ensuring rigidity and strength, good maintenance performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

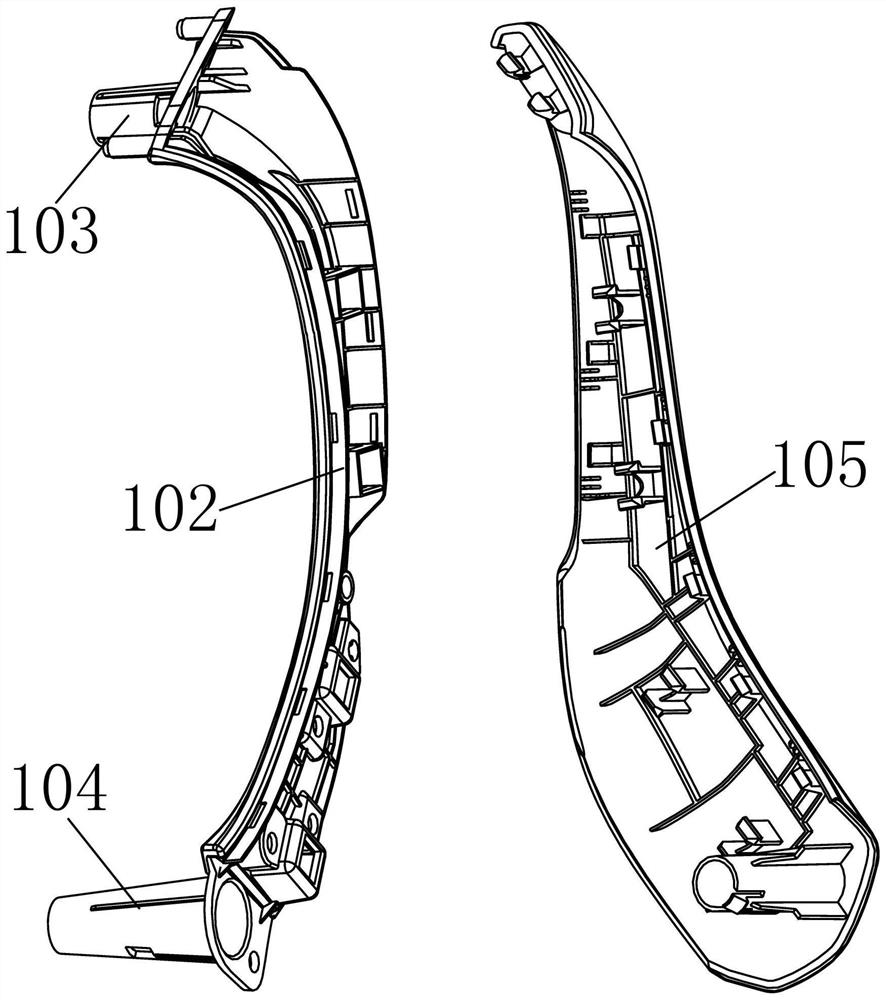

[0031] Such as Figure 5 One of the monofunctional vehicle facilities, including the tube-shaped armrest 1, and the upper end of the arm handle 1 extends upwardly, the insertion portion 2 is used to insert up to the door interior plate assembly. In the insertion tank 16 on the 10, a first connecting hole 3 in the outer direction is provided on the opening portion 2; the lower end portion of the armrest 1 is provided with the insert portion 7, and the insert portion 7 is used to facilitate the direction of the vehicle. In the inquiry tank embedded to the door interior 10, the second connection hole 8 in the outer direction is provided on the outer direction of the vehicle door. In the present embodiment, the armrest 1 can be a hollow tubular member made of an auxiliary process injection molding, and the armrest 1 can also be hollow tubular parts made of other processes.

[0032] In the present embodiment, in order to facilitate the mounting of the armrest 1 and adapt to the shape of...

Embodiment 2

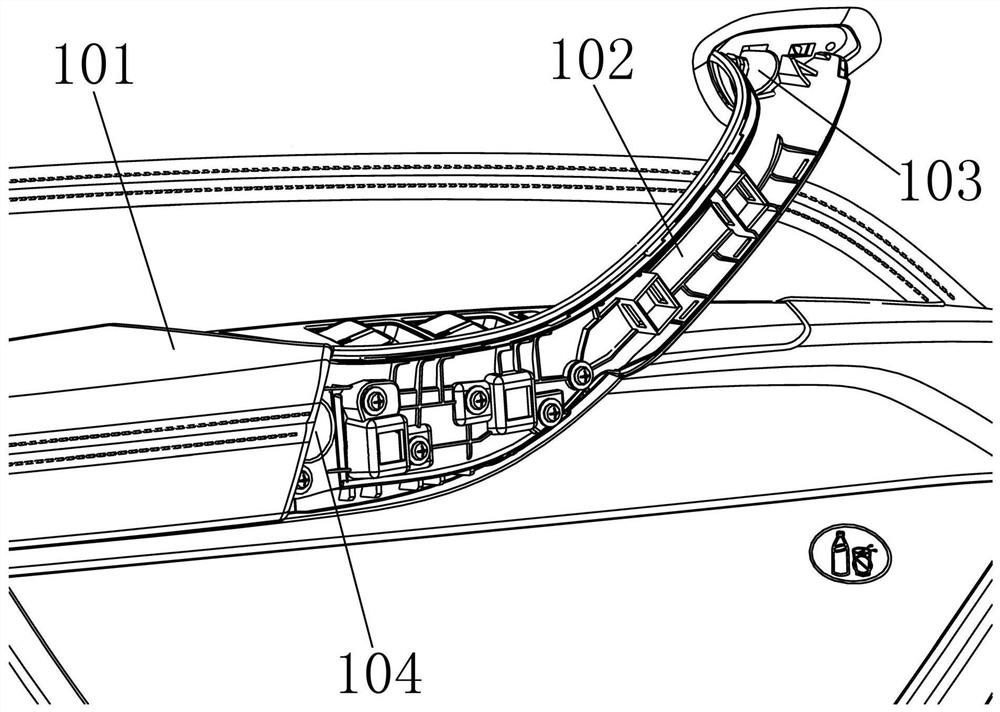

[0038] Such as Figure 2 to 9 A monocular car door handrail mounting structure, including a vehicle endojet assembly 10 and an embodiment of the integral vehicle facing handle 15, an upper portion of the door interior plate assembly 10 is provided with a plug-in groove 16. The middle portion of the door interior plate assembly 10 is provided with a tank, and the insertion portion 2 is inserted into the insertion groove 16, and the insert portion 7 is embedded in the inrangement slot.

[0039] In the present embodiment, the integral vehicle door handrail mounting structure further includes an upper connection bracket 17 and a first screw 18, and the upper connection bracket 17 is located on one side of the vehicle door interior plate assembly 10, and the first screw 18 is sequentially The upper connection bore 3 is connected to the first attachment hole 3 through the bottom groove wall of the upper connection bracket 17 and the insertion tank 16, and the upper connection bracket 17 ...

Embodiment 3

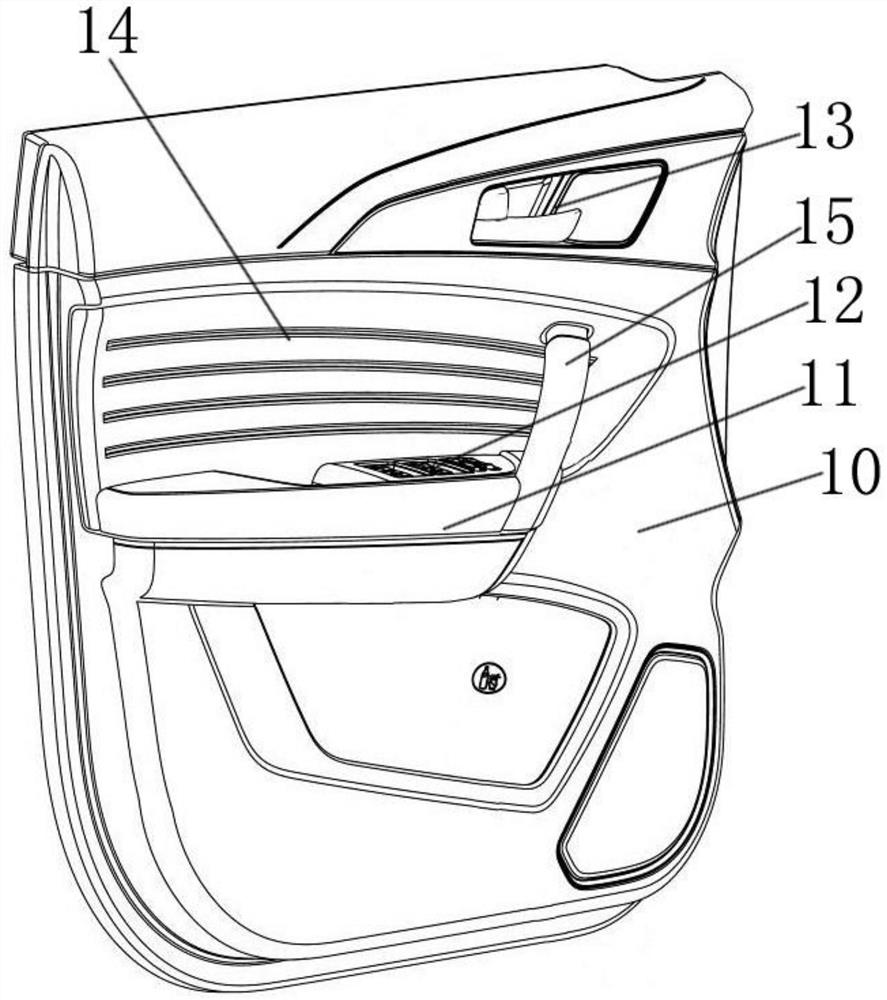

[0044] Such as Figure 10 to 12 As shown, the difference between the present embodiment and the second embodiment is that the lower connection bracket 23 is further provided, and the lower connection bracket 23 is located on one side of the vehicle door interior plate assembly 10, and the second screw 21 passes through the next connection. The groove wall of the bracket 23 and the socket is connected to the second connecting hole 8, and the lower connection bracket 23 is provided with a sixth connection hole 28 for connecting to the door sheet metal.

[0045] In the present embodiment, the middle portion of the door interior plate assembly 10 is provided with a support armrest 11 in the front-rear direction, and the upper side wall of the support armrest 11 is provided with a mounting opening for mounting the switch panel assembly 12; a lower connection bracket 23 is U-shaped, the lower connection bracket 23 includes a transverse segment 25, a first vertical segment 26 extending up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com