Thermal control method for aerospace equipment

A technology for aerospace equipment and thermal control, which is applied to the devices for controlling the living conditions of space vehicles, etc., can solve the problems of long time consumption, burnout of resistance elements, hindering the heat transfer relationship between the heater and the surface of the controlled object, etc., and achieve good filling. ability, saving curing time, and the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

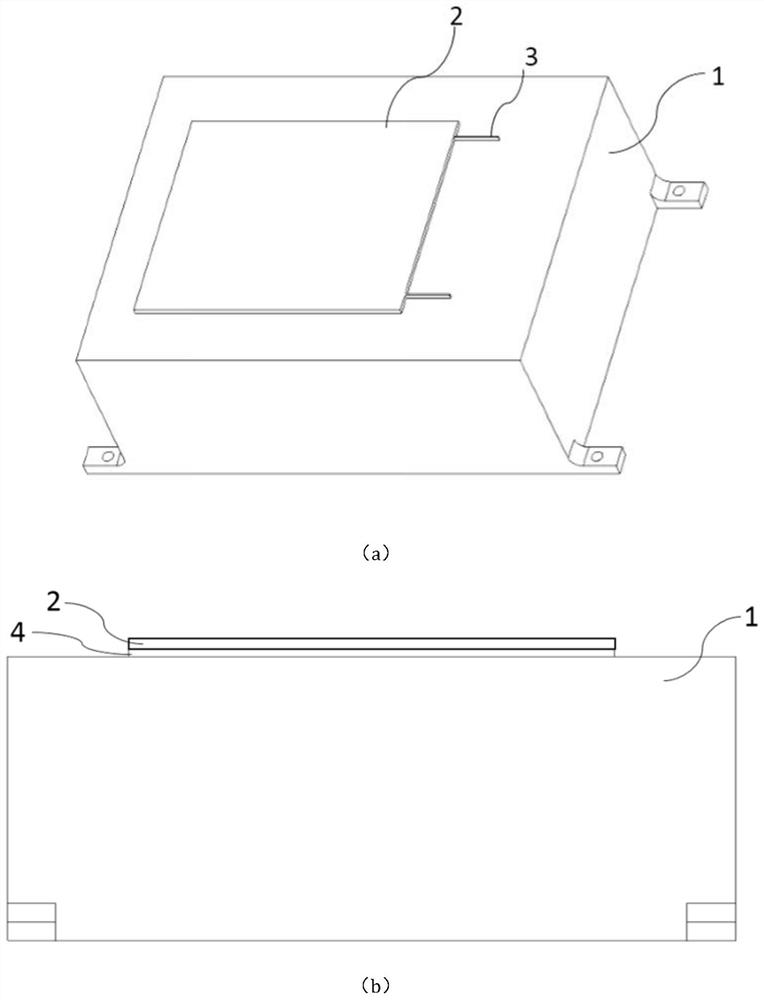

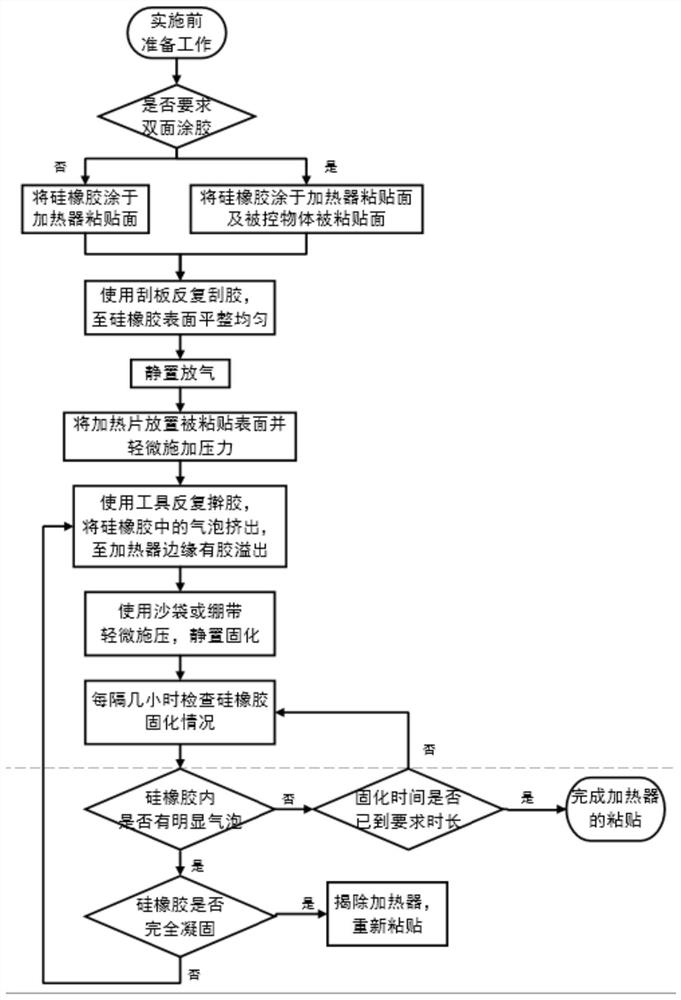

[0036] In order to make the technical solutions and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

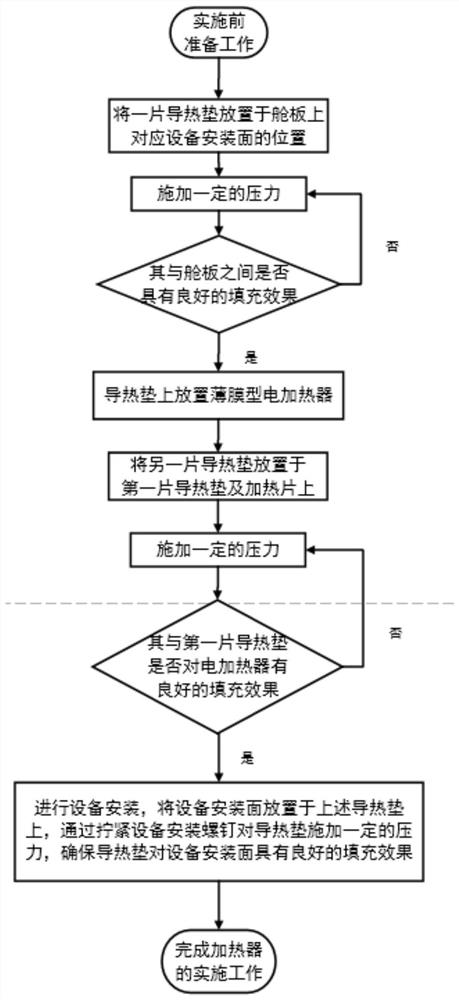

[0037] combine image 3 and Figure 4 A thermal control method for aerospace equipment according to an embodiment of the present invention is described. The methods include:

[0038] S100, disposing the first packing 5 on the deck 6 at a position corresponding to the installation surface of the aerospace equipment (that is, the controlled object) to be installed.

[0039] In a specific example, the first filler is a low interface thermal resistance filler, such as a therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com