Method for treating and recycling high-salinity industrial wastewater

An industrial wastewater, high salinity technology, applied in heating water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

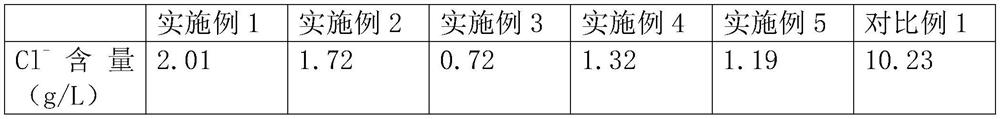

Embodiment 1

[0021] A method for the treatment and recycling of high-salinity industrial waste water, to high-salinity industrial waste water (Cl - content greater than 40g / L), add ethanol (the volume ratio of high-salinity industrial wastewater and ethanol is 1:1), after standing for 1h, salt precipitates, filter, and evaporate to Cl at 40°C - Concentration less than 3g / L, recycling.

Embodiment 2

[0023] A method for the treatment and recycling of high-salinity industrial waste water, to high-salinity industrial waste water (Cl - content greater than 40g / L), add propanol (the volume ratio of high-salinity industrial wastewater and propanol is 5:1), after standing for 3 hours, salt precipitates, filter, and evaporate to Cl at 65°C - Concentration less than 3g / L, recycling.

Embodiment 3

[0025] A method for the treatment and recycling of high-salinity industrial waste water, to high-salinity industrial waste water (Cl - content greater than 40g / L), add cyclohexanone (the volume ratio of high-salinity industrial wastewater and cyclohexanone is 3:1), after standing for 2 hours, salt precipitates, filter, and evaporate to Cl at 55°C - Concentration less than 3g / L, recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com