Volatile oil extraction separator

A technology of separator and volatile oil, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of incomplete oil extraction, lower oil yield, and affect oil yield, so as to improve stability, improve fluidity, and obtain The effect of increasing the oil rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

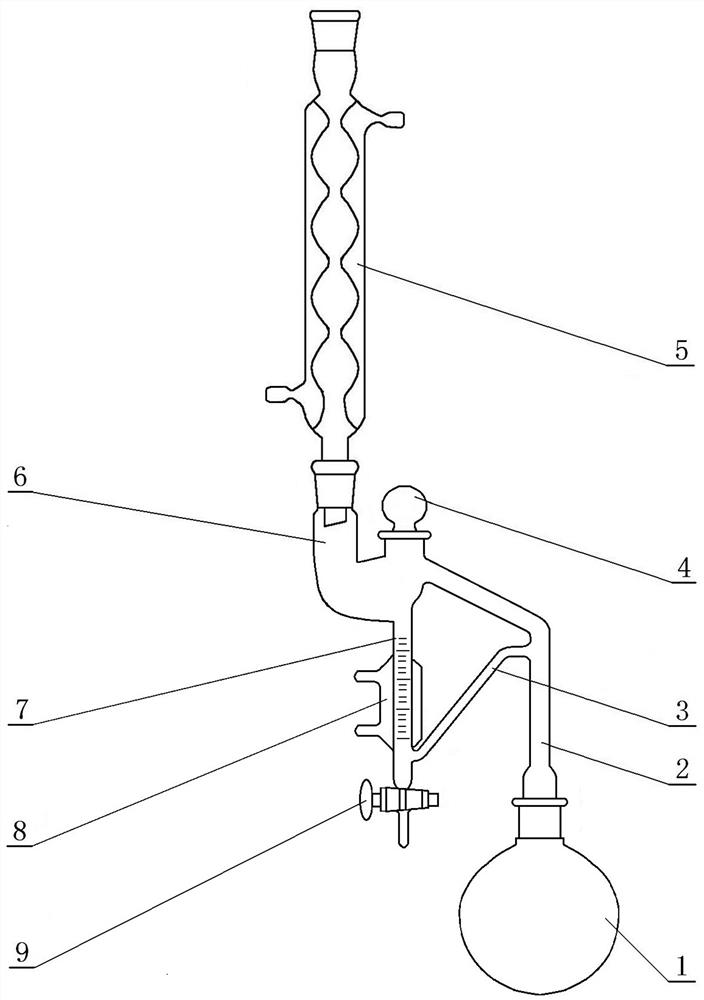

[0016] Embodiment 1: the present invention is the improvement to existing volatile oil extraction device, as figure 1 As shown, this volatile oil extraction separator includes a steam outlet pipe 2 connected to the distillation bottle 1, and the steam outlet pipe 2 is respectively connected with the buffer pipe 6 and the upper nozzle of the overflow pipe 3, and the buffer pipe 6 is connected with the first A condenser 5, the lower part of the buffer tube 6 forms a bent end, and the bottom of the bent end is connected to the top entrance of the measuring tube 7, the inner diameter of the measuring tube 7 is smaller than the inner diameter of the buffering tube 6, and the lower part of the measuring tube 7 The outlet is connected to the lower nozzle of the inclined overflow pipe 3, a valve 9 is installed at the outlet end of the bottom of the measuring pipe 7, and an opening is set at the top of the bending end of the corresponding measuring pipe 7, that is, a volatile oil intake...

Embodiment 2

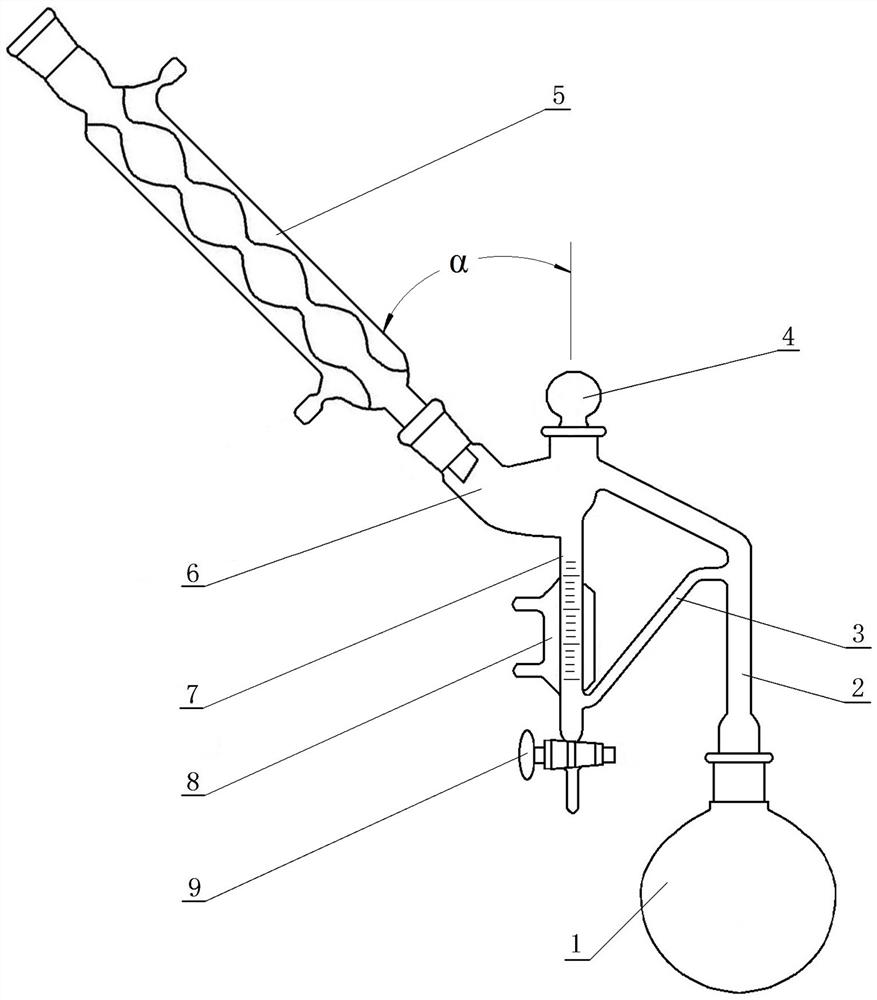

[0017] Embodiment 2: as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the angle α between the axis of the buffer tube 6 in the vertical section and the axis of the measuring tube 7 is 45°, that is, the orientation of the buffer tube 6 is different from that of Embodiment 1, In Embodiment 1, the interface between the buffer pipe 6 and the first condenser 5 is vertically upward. In this embodiment, since the interface between the buffer pipe 6 and the first condenser 5 faces upward at 45°, the condensation of the first condenser 5 is released. The liquid droplets can slowly flow into the measuring tube 7 along the wall of the inclined buffer tube 6, so as to avoid disturbing the oil surface in the measuring tube 7 and improve the separation effect of volatile oil and water.

[0018] When the present invention is used, the oil-water vapor mixture in the distillation bottle 1 enters the first condenser 5 through the steam outlet pipe 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com