Hybrid construction machinery hydraulic system and hybrid construction machinery

A technology of construction machinery and hybrid power, which is applied in the hydraulic system of hybrid power construction machinery and the field of hybrid power construction machinery, can solve problems such as increased cost, limited energy of accumulators, and increased number of components, and achieve the effect of increasing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

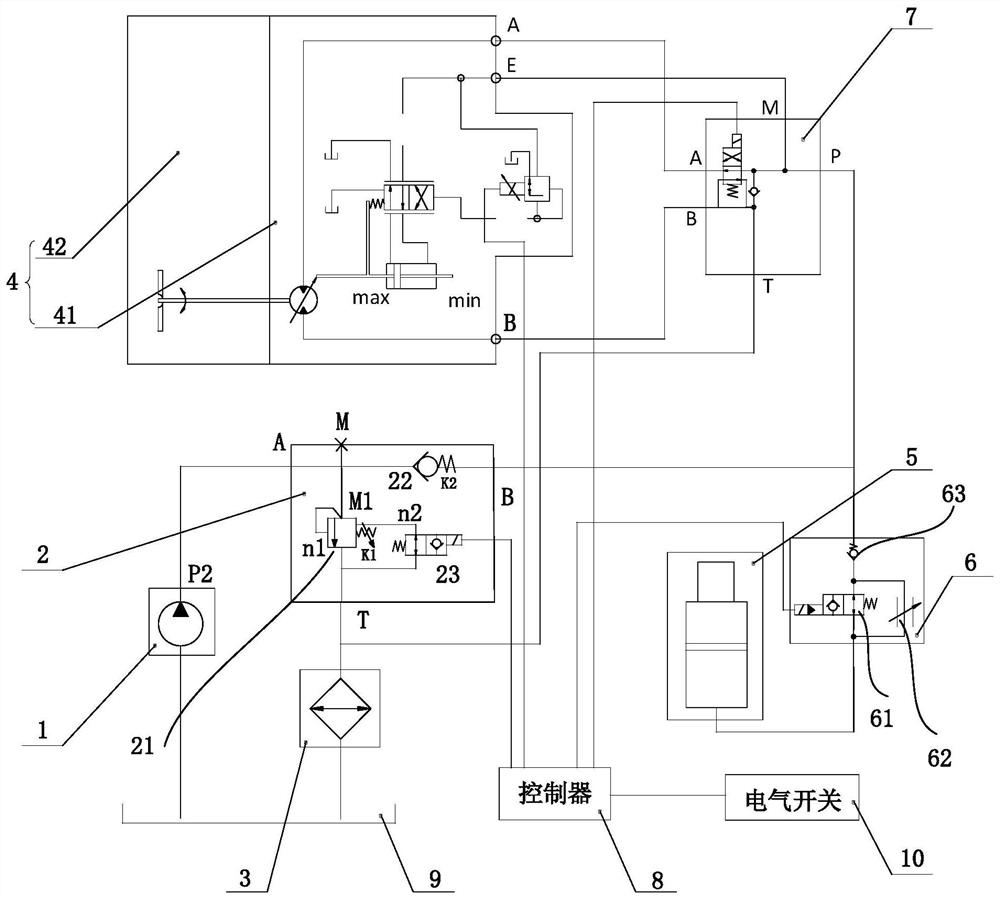

[0038] Combine below figure 1 The technical solutions provided by the present invention are described in more detail.

[0039] The embodiment of the present invention provides a hydraulic system of a hybrid construction machinery, including a pump 1 , a switching valve group 2 , a cooler 3 , an actuator 4 and an accumulator 5 .

[0040] The pump 1 is configured to pump oil. The pump 1 is drivingly connected to the engine of the hybrid construction machine. When the hybrid construction machine is turned on, the engine works all the time, and the pump 1 also works all the time. The oil pumped by the pump 1 has two flow directions, and these two flow directions are related to the valve position state of the switching valve group 2. According to the valve position state of the switching valve group 2 , the oil output from the pump 1 can be switched to one of the cooler 3 and the actuator 4 . If the oil delivered by the accumulator 5 is sufficient to drive the actuator 4 to work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com