Middle cover structure for oil-gas separation of hydraulic retarder

A technology of hydraulic retarder and cover structure, which is applied in the field of auto parts, and can solve the problems of poor control accuracy of vehicle constant kinetic energy, reduced braking performance of hydraulic retarder, lack of working oil of retarder, etc. , to achieve the effects of easy processing, improved speed control accuracy, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

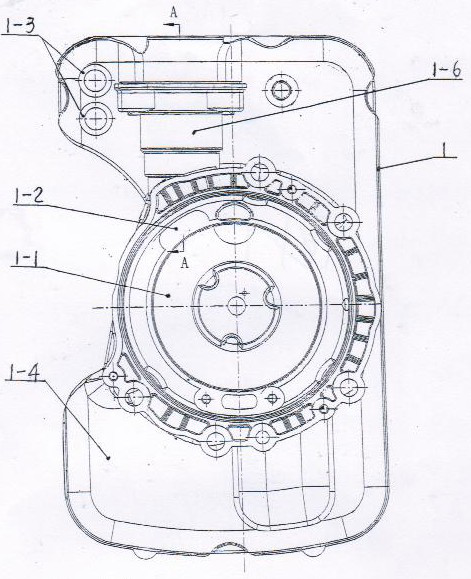

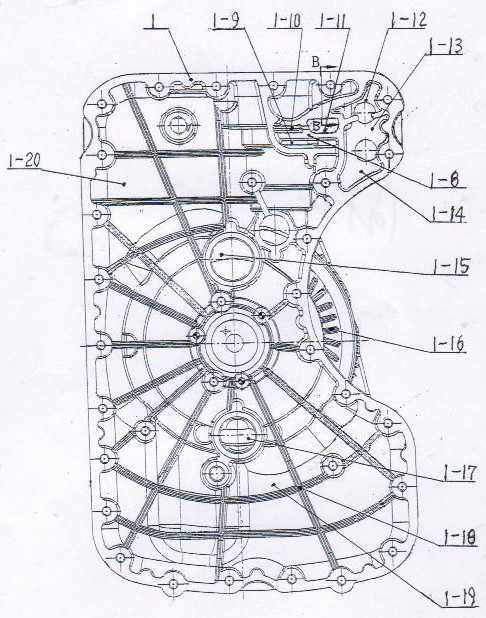

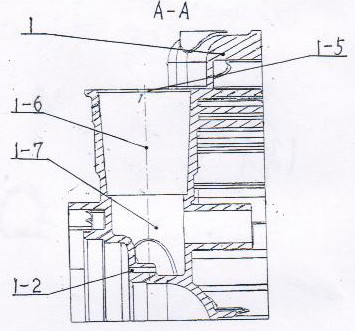

[0012] Examples, see attached Figure 1~4 , the front side of the middle cover 1 in the middle cover structure of the oil-gas separation of the hydraulic retarder is the side 1-4 connected with the front cover, and the rear side of the middle cover 1 is the side 1-20 connected with the rear cover. The middle of the side 1-4 connected with the front cover is the working chamber 1-1, the working chamber 1-1 is composed of a circular step hole and a large arc surface, and the step surface in the working chamber is provided with an exhaust hole 1-2. The upper end of the working chamber 1-1 is the oil-gas separation chamber 1-5, the upper end of the oil-gas separation chamber 1-5 is the oil-gas separator installation hole 1-6, the lower end is the working chamber oil-gas separation chamber 1-7, the working chamber oil-gas separation chamber 1 -7 communicates with the working chamber 1-1 through the exhaust hole 1-2, and there are two muffler installation holes 1-3 on the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com