A Finishing Device for Cylindrical Ice Specimen

A technology for cylindrical and test pieces, which is applied in the field of finishing devices, can solve the problems of single size of ice test pieces and lack of truncation function, and achieve the effect of uniform specifications and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

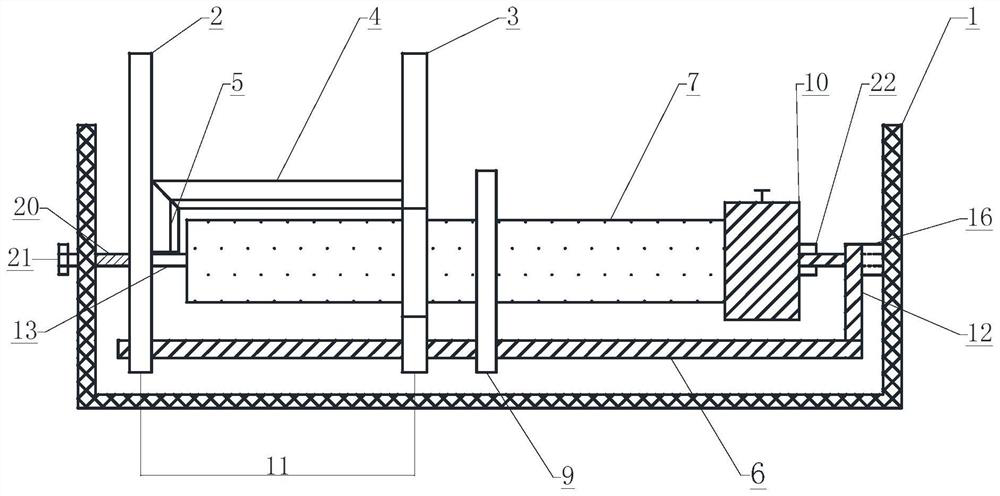

[0036] Implementation case 1, finishing cylindrical ice specimen:

[0037] Hold the ice specimen to be processed:

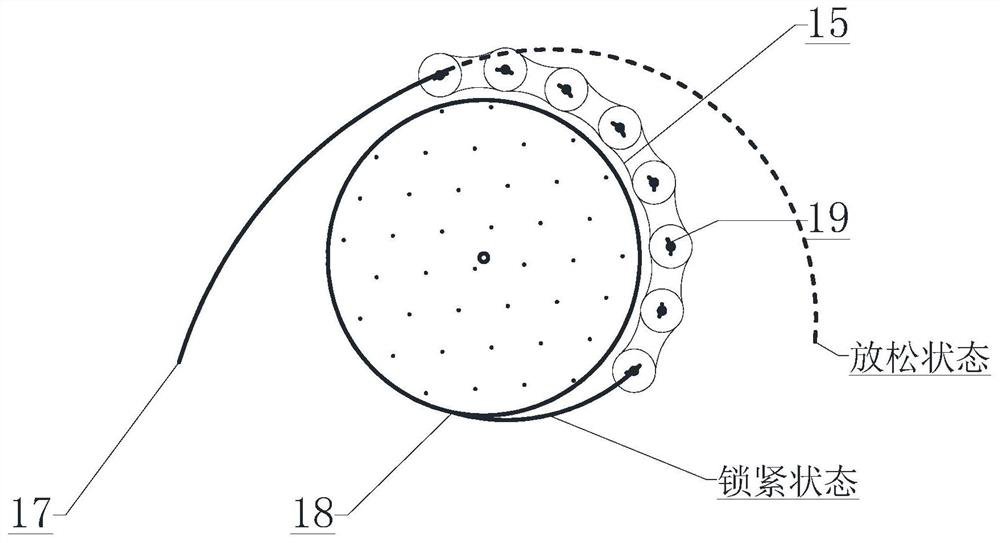

[0038] The operator grabs the ice specimen to be processed with the left hand, pulls the locking hinge head 18 with the right hand, and then passes the ice specimen to be processed through the center of the locking hinge 9, puts it into the fixture for clamping, and tightens the locking screw at the right end for axial restraint .

[0039] To cut one end of an ice specimen:

[0040] Constantly adjust the left and right positions of the cutter set 11 so that the radial blade 5 is close to the left end of the ice test piece 7 . The position of the circumferential blade 4 is continuously adjusted so that the circumferential blade 4 is close to the outer wall of the ice test piece 7 . Lift and press the cutting handle downward and reciprocatingly. At this time, the radial blade 5 will cut the left end of the ice test piece 7 to reduce the length of the ice test pi...

Embodiment example 2

[0045] Example 2: A disc-shaped ice specimen was obtained by finishing.

[0046]First, complete the step of "holding the ice specimen to be processed" in the above "implementation case 1".

[0047] Truncated ice specimen:

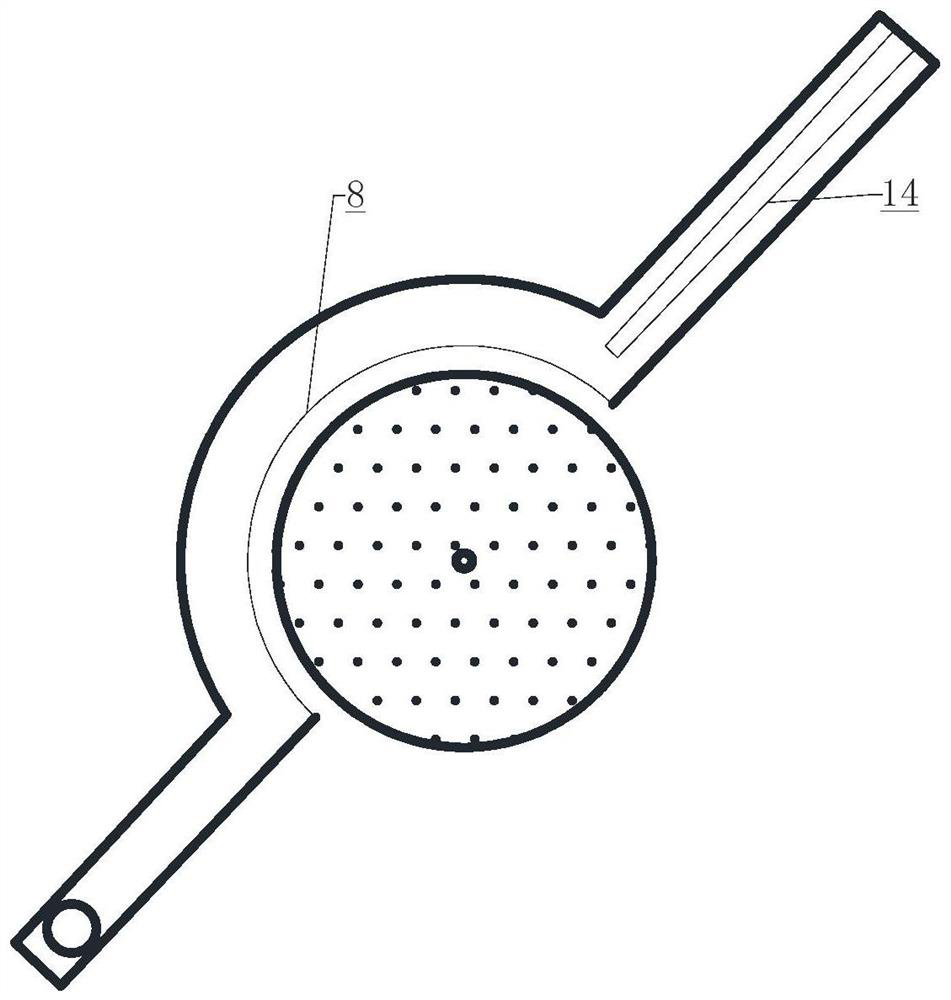

[0048] The cutter set 11 is adjusted so that both the circumferential blade 4 and the radial blade 5 on the cutting handle 2 are slightly away from the ice test piece 7 . Adjust the left and right positions of the truncation handle. Press down the cutting handle 3 and place the cutting handle on the side close to the operator. Hold the cutting handle 2 in the left hand and the cutting handle 3 in the right hand. The left and right hands swing up and down together, and the swing range will be larger than the cutting range.

[0049] When the aforementioned two handles move downward, the cutting blade 8 will cut the ice test piece 7 and cut a dent on the ice test piece 7; Lift, do not cut. At the same time, the ice specimen 7 is controlled by the synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com