High-precision polarization-maintaining optical fiber loop curing method

A technology of polarization-maintaining optical fiber rings and optical fiber rings, which can be used in measuring devices, instruments, surveying and navigation, etc. It can solve problems such as complex structure, difficulty in UV light transmission, and affecting the performance of optical fiber rings, so as to reduce the impact and internal stress. Uniform distribution, the effect of improving temperature performance and vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

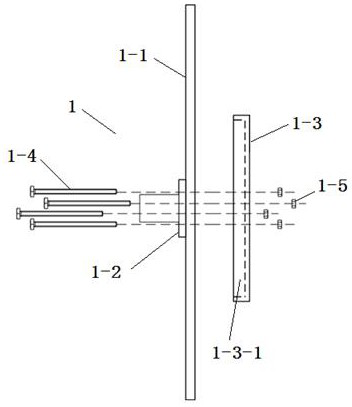

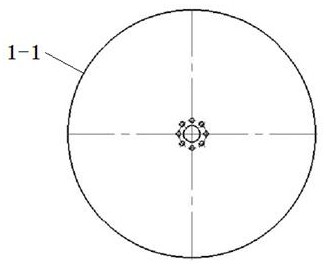

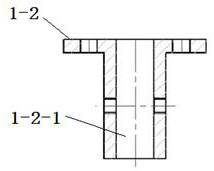

[0033] Step 1. Place one end of a 48-layer polarization-maintaining optical fiber ring 2 wound by an optical fiber with a diameter of 165 μm on the end surface of the metal disc 1-1 without bearing sleeve 1-2, and fasten the optical fiber on the metal circular cover plate 1-3 On the other end of the ring 2, place the optical fiber ring in the circular groove 1-3-1 of the metal circular cover plate 1-3, and pass the four bolts 1-4 through the circular end of the bearing sleeve 1-2 in turn 4 holes, 4 holes of the metal disc 1-1, fiber ring 2, 4 holes of the metal round cover 1-3 are screwed with nuts 1-5, and the fiber ring 2 is fixed on the rotary curing tray 1 superior;

[0034] Step 2. Fix the rotary curing tray 1 on the motor shaft through the shaft hole 1-2-1 of the raised end of the bearing sleeve 1-2 and the motor shaft, turn on the motor, and the motor shaft drives the rotary curing tray 1 to rotate at a constant speed, and the rotating speed Adjust to 10 rpm;

[0035]...

no. 2 example

[0038] Step 1. Put one end of a 64-layer polarization-maintaining optical fiber ring 2 wound by an optical fiber with a diameter of 165 μm on the end surface of the metal disc 1-1 without bearing sleeve 1-2, and fasten the metal circular cover plate 1-3 on the On the other end of the optical fiber ring 2, place the optical fiber ring in the circular groove 1-3-1 of the metal circular cover plate 1-3, and pass the four bolts 1-4 through the round surface of the bearing sleeve 1-2 in turn The 4 holes at the end, the 4 holes of the metal disc 1-1, the fiber ring 2, the 4 holes of the metal round cover 1-3 are screwed with the nuts 1-5, and the fiber ring 2 is fixed on the rotary curing tray 1 on;

[0039] Step 2. Fix the rotary curing tray 1 on the motor shaft through the shaft hole 1-2-1 of the raised end of the bearing sleeve 1-2 and the motor shaft, turn on the motor, and the motor shaft drives the rotary curing tray 1 to rotate at a constant speed, and the rotating speed Adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com