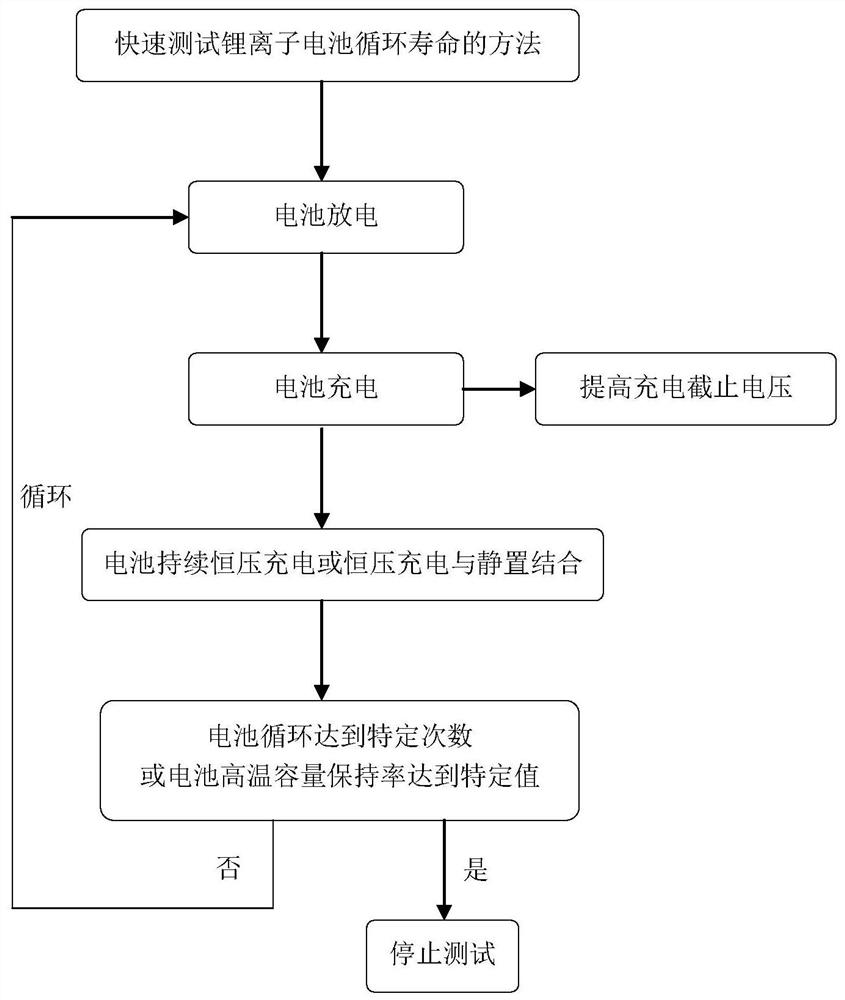

Method for rapidly testing cycle life of lithium ion battery

A lithium-ion battery, cycle life technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problem of long cycle life testing, etc., to facilitate rapid development, accelerate the occurrence of various side reactions, and shorten the test laboratory. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the present invention will be further described in connection with the specific embodiments. It should be understood that the following examples are merely illustrative and explained, and it is not to be construed as limiting the scope of the invention. The techniques implemented by the above-described above-described above are covered in the scope of the invention.

[0053] The experimental methods used in the following examples are not particularly illustrative, all of which are conventional methods; reagents, materials used in the following examples, such as non-special instructions, can be obtained from the business pathway.

Embodiment 1

[0055] The lithium ion battery is made according to a conventional manufacturing process, and the positive electrode active material is lithium cobaltate, and the negative electrode active material is graphite, and the battery design capacity is 4000 mAh. The charging upper limit of the charging upper limit of the lithium ion battery is 4.35V, and the known discharge lower limit voltage is 3.0 V.

[0056] Place the lithium ion battery in a 45 ° C environment, the test process is as follows:

[0057] Discharge the charged lithium ion battery, the discharge process is discharged to 3.0V at a discharge ratio of 0.5c, and then the discharge is allowed to stand for 10 min;

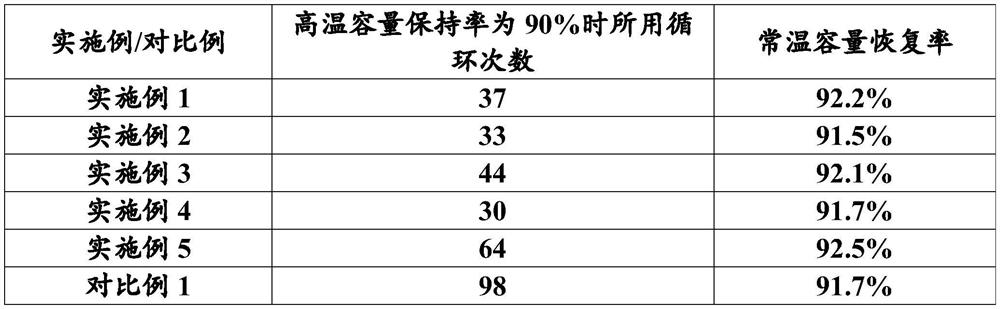

[0058] Charge the lithium-ion battery after the discharge, charged to 4.4V at 0.7c rate, then constant pressure charging under 4.4V constant pressure, adjust the time of constant voltage charging, so that the total time of each cycle is 24 hours When the recording capacity retention ratio is 90%, the result is as s...

Embodiment 2

[0060] The lithium ion battery is the same as in Example 1, and the test method is different from that of Example 1.

[0061] The test method of this embodiment is as follows:

[0062] Place the lithium ion battery in a 50 ° C environment, the test process is as follows:

[0063] Discharge the charged lithium ion battery, the discharge process is discharged to 3.0V at a discharge ratio of 0.5c, and then the discharge is allowed to stand for 10 min;

[0064] Charging the lithium ion battery after discharge, the charging process at 8 laps before the lithium ion battery is: charged to 4.4V at 0.7c rate, then constant pressure charging under 4.4V constant pressure, adjust constant pressure charge charge Time, the total time each cycle is 24 hours;

[0065] From the first 9th circle, the charging process of the lithium ion battery is: charged to 4.36V at 0.7c rate, then constant pressure charging under 4.36V constant pressure, adjust the time of constant voltage charging, so that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com