Method for rapidly testing cycle life of lithium ion battery

A lithium-ion battery, cycle life technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problem of long cycle life test, and achieve the effect of being conducive to rapid development, fast battery decay, and accelerated battery decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

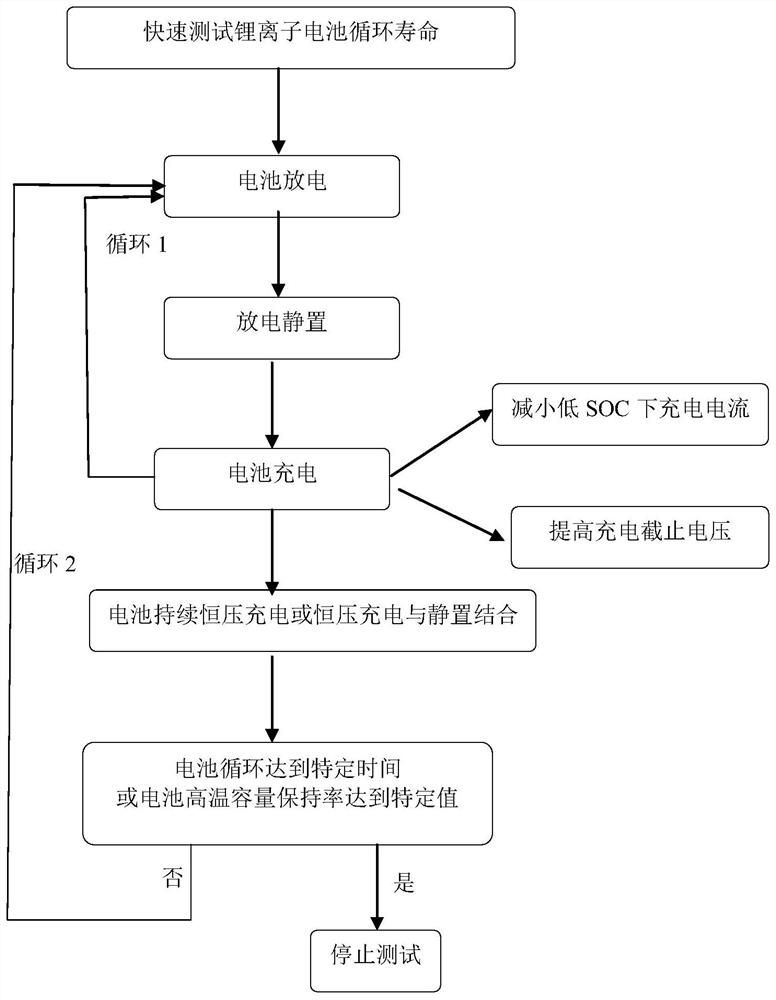

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0078] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0080] The lithium-ion battery is produced according to the conventional manufacturing process, the positive electrode active material is lithium cobaltate, the negative electrode active material is graphite, and the battery design capacity is 4000mAh. The known charging upper limit voltage of the lithium ion battery is 4.35V, the known discharging lower limit voltage is 3.0V, and the known charging rate is 0.7C.

[0081] Place the lithium-ion battery in an environment of 45°C, and the test process is as follows:

[0082] Discharge the fully charged lithium-ion battery. The discharge process is to use 0.5C to discharge to 3.0V, and then discharge and stand for 10 minutes;

[0083] To charge the discharged lithium-ion battery, first use 0.1C to charge to 80% of the designed capacity, and then charge to 4.38V at a rate of 0.7C. After charging for 100 hours, after the end of the constant voltage, the discharge step was started to carry out a nested cycle, and the corresponding c...

Embodiment 2

[0085] The lithium ion battery is the same as in Example 1, and the test method is different from Example 1.

[0086] The test method of this embodiment is as follows:

[0087] Place the lithium-ion battery in an environment of 50°C, and the test process is as follows:

[0088] Discharge the fully charged lithium-ion battery. The discharge process is to discharge to 3.0V at 0.5C, and then discharge and stand for 30min;

[0089] To charge the discharged lithium-ion battery, first use 0.1C to charge to 40% of the design capacity, then use 0.3C to charge to 70% of the design capacity, and then use 0.7C to charge to 4.4V, the above charge and discharge cycles are carried out for 3 Then start charging at 4.4V for 30 hours at a constant voltage, and then let it stand for 20 hours. After the above test is completed, enter the discharge step to perform a nested cycle. Record the corresponding cycle time when the capacity retention rate reaches 90%. The results are shown in Table 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com