Mobile maintenance safety monitoring system

A safety monitoring system and mobile technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as overhaul safety in oil refineries and petrochemical plants, and facilitate the inquiry of work progress and improve standards. Sex and safety, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

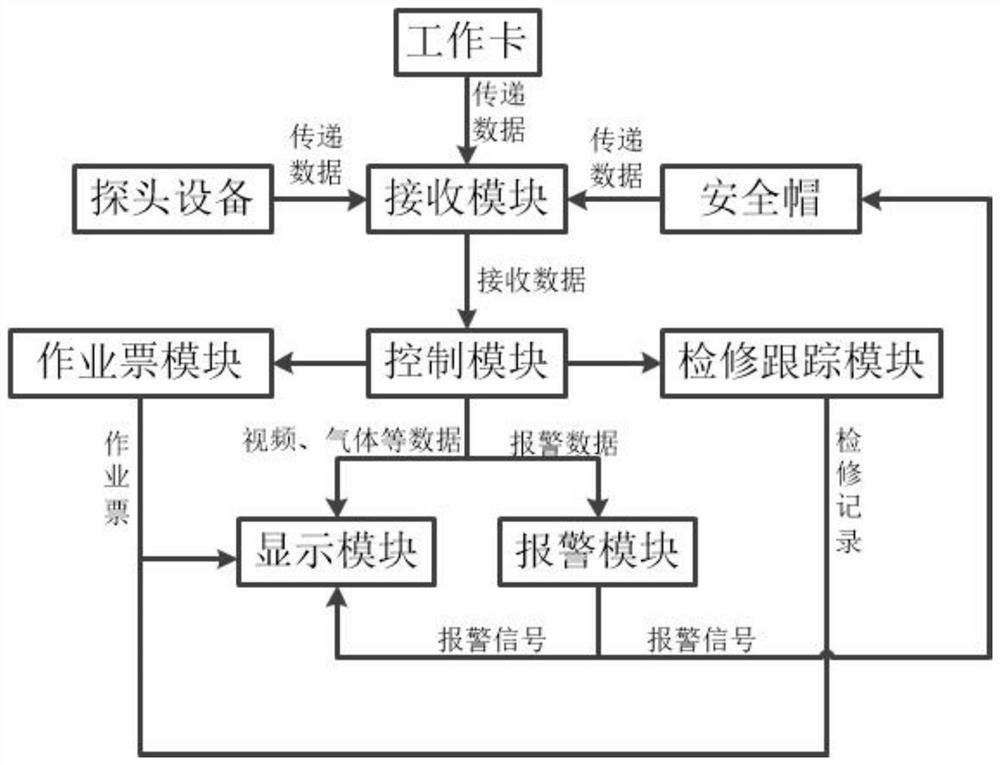

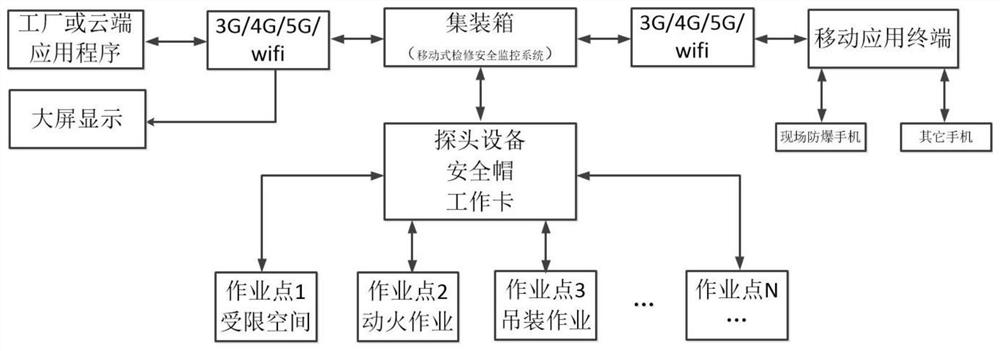

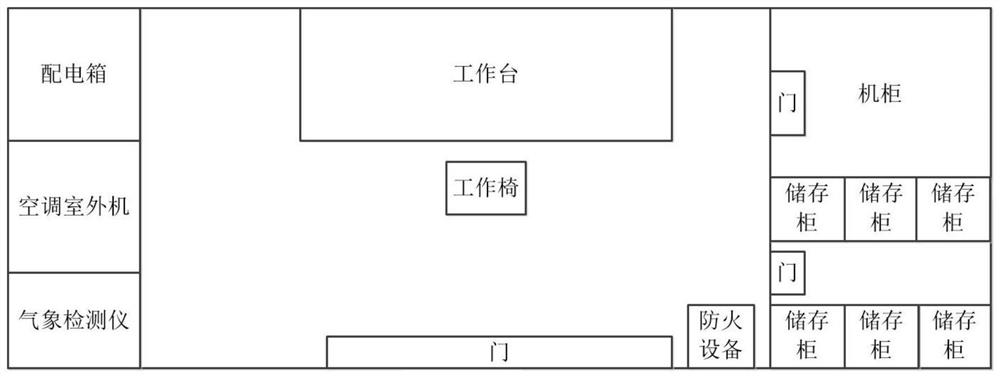

[0032] see Figure 1-5 , the present embodiment provides a mobile overhaul safety monitoring system, including a central control room, a safety helmet, probe equipment, and a work card; the central control room includes a receiving module, an alarm module, a control module, a display module, and a job ticket module . Maintenance and tracking module; the central control room communicates with the safety helmet, the probe equipment and the work card respectively. The safety helmet includes a digital module, a positioning module, a video module, a lighting module, and a voice module; the receiving module is connected to the digital module, the positioning module, the video module, the lighting module, and the voice module through communication. The probe equipment includes a gas probe, a video probe, and a weather probe; the receiving module communicates with the gas probe, the video probe, and the weather probe; the functions of the work card include sign-in and positioning; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com