Constant-temperature warm-keeping knitted fabric

A knitted fabric and constant temperature technology, which is applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of thermal insulation effect to be improved, achieve improved thermal insulation and thermal comfort, strong thermal effect, and improved yarn quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the constant temperature and warm knitted fabric comprises the following steps:

[0035] S1: Spinning: put Dralon acrylic fiber, graphene viscose staple fiber, viscose fiber, coffee charcoal polyester, and bamboo charcoal polyester into the cotton grabbing machine to grab the cotton fiber, and then put the cotton fiber into the automatic cotton blender for box mixing. The mixed cotton fiber enters the single-roller cleaning machine to remove the impurities, and the cotton fiber after the impurity removal enters the vibrating box cotton feeding machine for cotton fiber transportation, and is transported to the single-hand roll machine to form Then enter the carding machine for opening, carding and impurity removal, so that all the coiled cotton loops become basically straight single fibers. In the process, the broken seeds left over from the cleaning process are removed , impurities and short fibers, and then integrate cotton slivers of certain ...

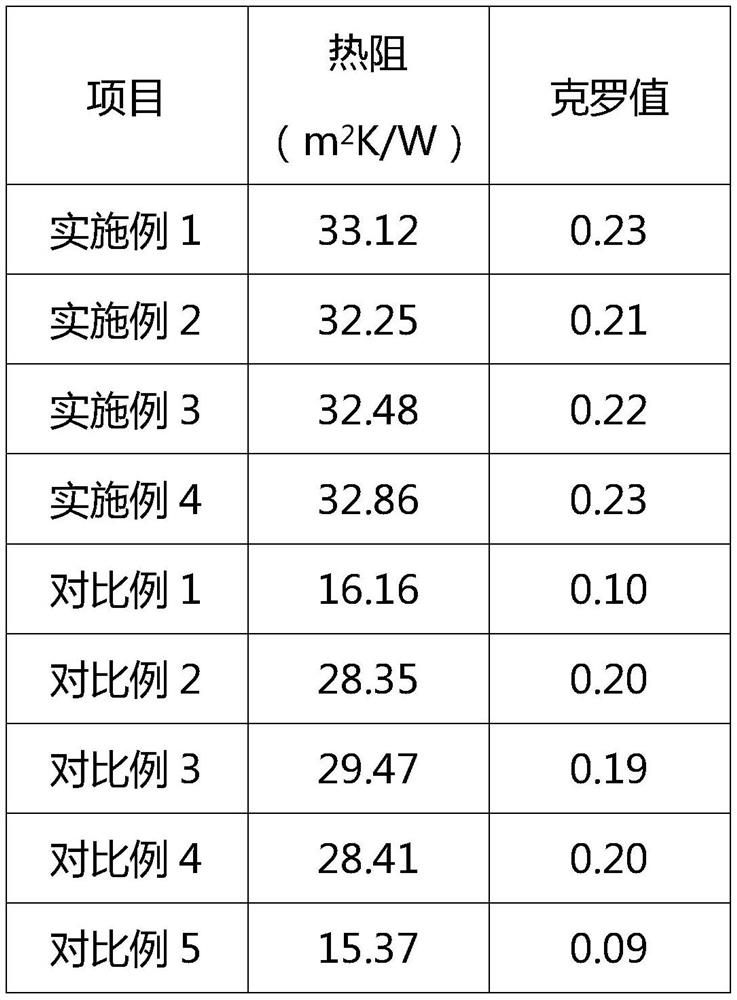

Embodiment 1

[0047] A constant temperature and warm knitted fabric, in parts by weight, comprising the following components: 14 parts of Dralon acrylic fiber, 6 parts of graphene viscose staple fiber, 8 parts of viscose fiber, 5 parts of coffee charcoal polyester, and 3 parts of bamboo charcoal polyester;

[0048] The preparation method of the constant temperature and warm knitted fabric comprises the following steps: S1: Spinning: put Dralon acrylic fiber, graphene viscose short fiber, viscose fiber, coffee charcoal polyester, bamboo charcoal polyester into cotton grabbing machine to grab cotton fiber respectively, After that, the cotton fiber is put into the automatic cotton mixer for box mixing, and the mixed cotton fiber enters the single-roller cleaning machine to remove the impurities, and the cotton fiber after the impurity removal enters the vibrating box feeder for further processing. Cotton fibers are transported into a single-hand lapping machine to form a roll, and then enter th...

Embodiment 2

[0060] A constant temperature and warm knitted fabric, in parts by weight, comprising the following components: 13 parts of Dralon acrylic fiber, 6 parts of graphene viscose staple fiber, 6 parts of viscose fiber, 4 parts of coffee charcoal polyester, and 1 part of bamboo charcoal polyester;

[0061] The preparation method of the constant temperature and warm knitted fabric comprises the following steps: S1: Spinning: put Dralon acrylic fiber, graphene viscose short fiber, viscose fiber, coffee charcoal polyester, bamboo charcoal polyester into cotton grabbing machine to grab cotton fiber respectively, After that, the cotton fiber is put into the automatic cotton mixer for box mixing, and the mixed cotton fiber enters the single-roller cleaning machine to remove the impurities, and the cotton fiber after the impurity removal enters the vibrating box feeder for further processing. Cotton fibers are transported into a single-hand lapping machine to form a roll, and then enter the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com