Method for cutting invisible tooth appliance based on six-axis industrial robot

A technology of orthodontic appliances and industrial robots, which is applied in the direction of manipulators, manufacturing tools, and comprehensive factory control, can solve problems such as high prices, and achieve the effects of improving processing accuracy, reducing costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

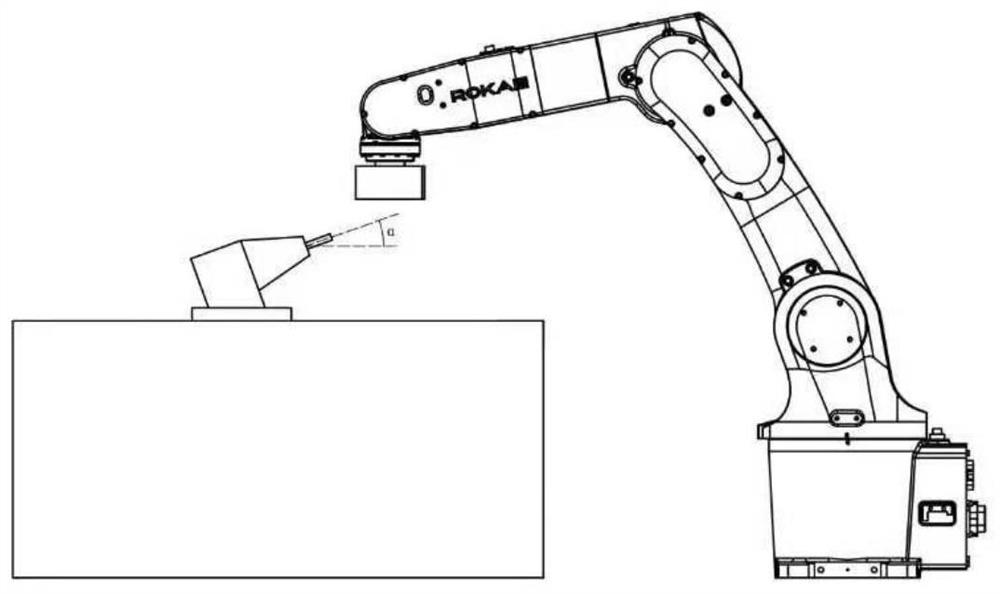

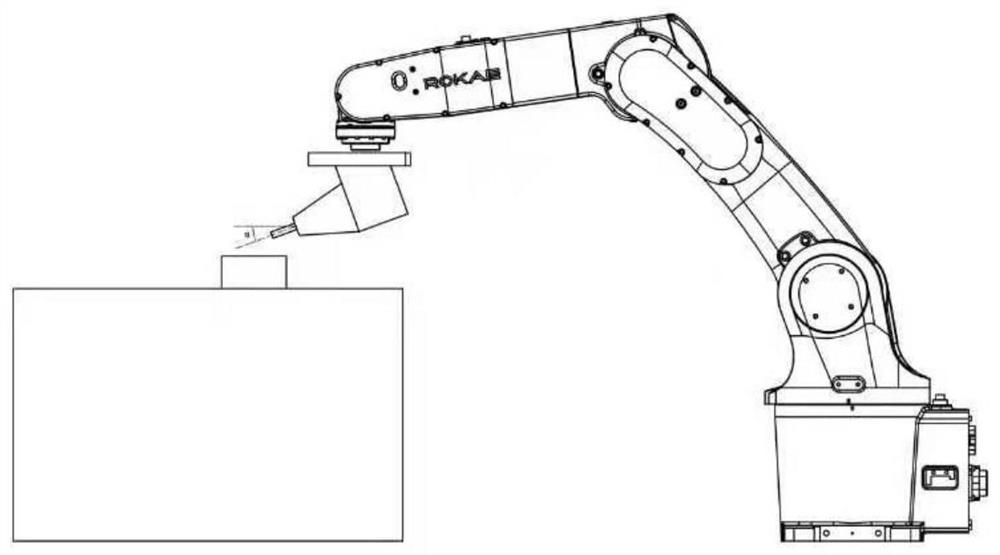

[0034] Such as figure 1 As shown, the method of the present invention based on the six-axis industrial robot cutting invisible dental appliance mainly includes the following steps:

[0035] S10, installing the cutting tool and the orthodontic device as the workpiece;

[0036] S20, completing the calibration of the cutting tool and the orthodontic appliance in step S10;

[0037] S30, obtaining and importing the dental membrane CAD file, and selecting a cutting path point;

[0038] S40, calculating the relative coordinate system of the cutting tool and the orthodontic appliance at each cutting path point;

[0039] S50, importing route information;

[0040] S60, the trial run robot completes the cutting, and performs error compensation according to the cutting effect;

[0041] S70, officially put into production;

[0042] Wherein st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com