Energy-saving and environment-protecting agricultural feed cutting equipment

A cutting equipment, energy saving and environmental protection technology, applied in feed, application, metal processing and other directions, can solve the problems of heavy workload, waste, feed splash, etc., to improve work efficiency, avoid waste and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

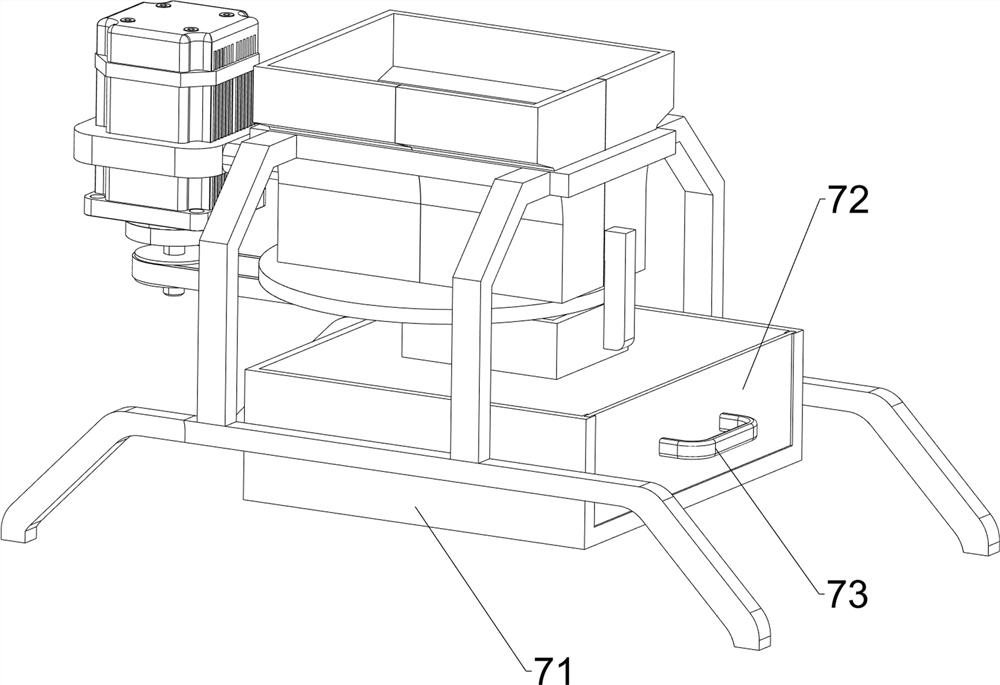

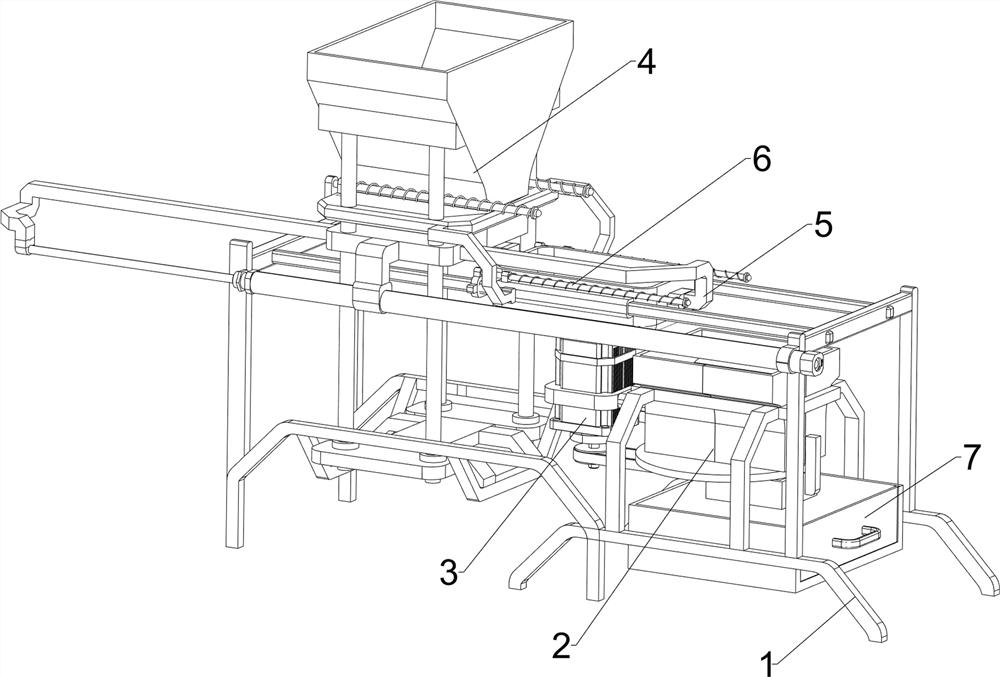

[0027] An energy-saving and environment-friendly agricultural feed cutting equipment, such as figure 1 and figure 2 As shown, it includes a base 1, a cutting mechanism 2 and a driving mechanism 3. The cutting mechanism 2 is arranged on the right side of the middle part of the base 1, and the driving mechanism 3 is arranged on the left side of the cutting mechanism 2.

[0028] The cutting mechanism 2 includes a first mounting frame 21, a material guide groove 22, a cutter 23 and a back-up ring 24, the base 1 bottom right side is provided with the first mounting frame 21 symmetrically front and back, and the first mounting frame 21 tops are provided with guides. The material trough 22 and the lower side of the material guide trough 22 are rotatably provided with a cutter 23 , and the bottom of the material guide trough 22 is provided with a retaining ring 24 .

[0029] Drive mechanism 3 comprises second mounting frame 31, motor 32, transmission wheel 33 and belt 34, and the le...

Embodiment 2

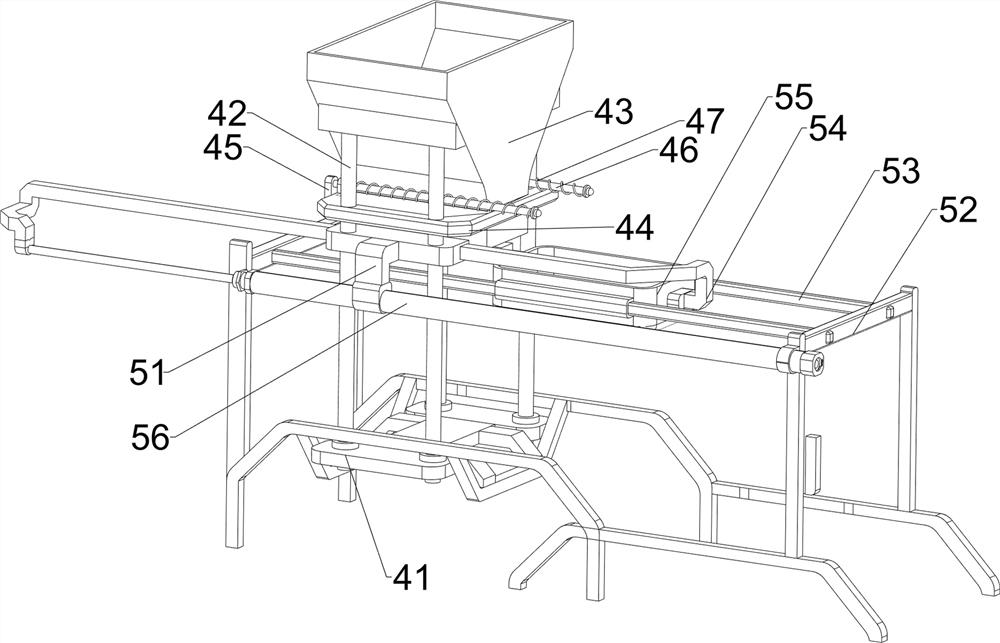

[0032] On the basis of Example 1, such as image 3 , Figure 4 and Figure 5 As shown, it also includes a material storage mechanism 4, and the material storage mechanism 4 includes a third mounting frame 41, a support column 42, a material storage tank 43, a first fixed frame 44, a first baffle plate 45, a first guide rod 46, The first spring 47 and the first push rod 48, the left side of the middle part of the base 1 is provided with a third installation frame 41, the top of the third installation frame 41 is provided with support columns 42 around, and a storage tank 43 is provided between the support column 42 tops, A first fixed frame 44 is arranged between the support column 42 and the storage tank 43, the middle part of the first fixed frame 44 is slidingly provided with a first baffle plate 45, and the top of the first fixed frame 44 is provided with a first guide rod symmetrically sliding forward and backward. 46, the left side of the first guide rod 46 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com