Inner cabin structure and underwater vehicle

A profile and top frame technology, applied to underwater ships, underwater operating equipment, ships, etc., can solve the problems of increased difficulty in wiring and sealing, heavy disassembly and maintenance tasks, and a large amount of watertight cables, etc., to achieve reduction Difficulty and failure rate, avoidance of unstable placement, effects of corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

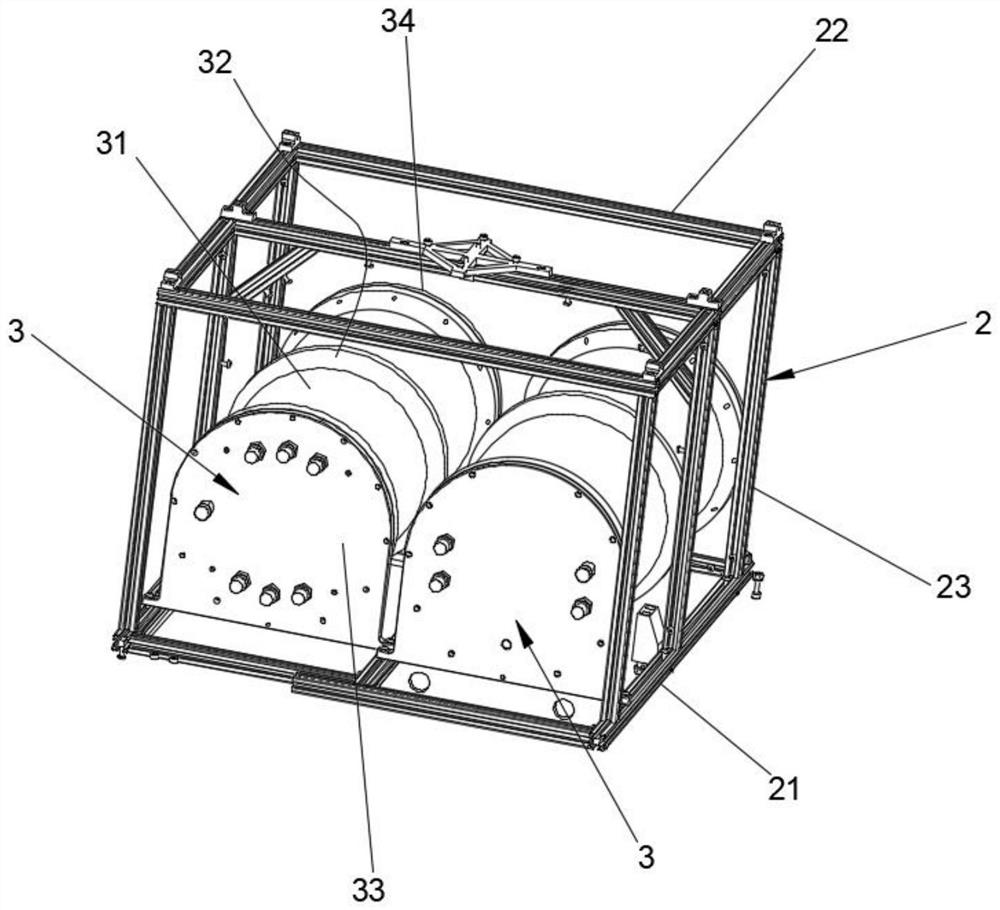

[0059] The above is the first embodiment of an inner cabin structure provided by the embodiment of the application, and the following is the second embodiment of an inner cabin structure provided by the embodiment of the application. For details, please refer to Figure 1 to Figure 9 .

[0060] Based on the scheme of the first embodiment above:

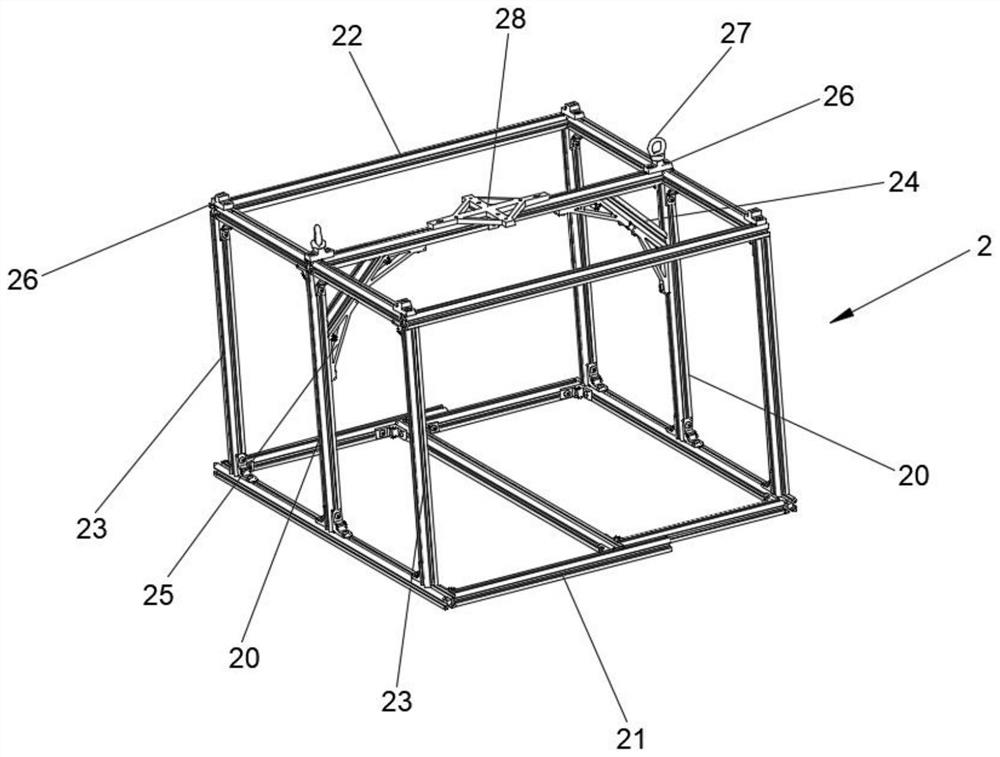

[0061] Further, as figure 1 As shown, the structure of the rigid frame 2 can be designed as a square cage structure, and a large regular space can be formed inside to meet the installation requirements. Specifically, there are four first connecting profiles 23; the four first connecting profiles 23 are respectively arranged between the four corners of the bottom frame 21 of the profile and the top frame 22 of the profile.

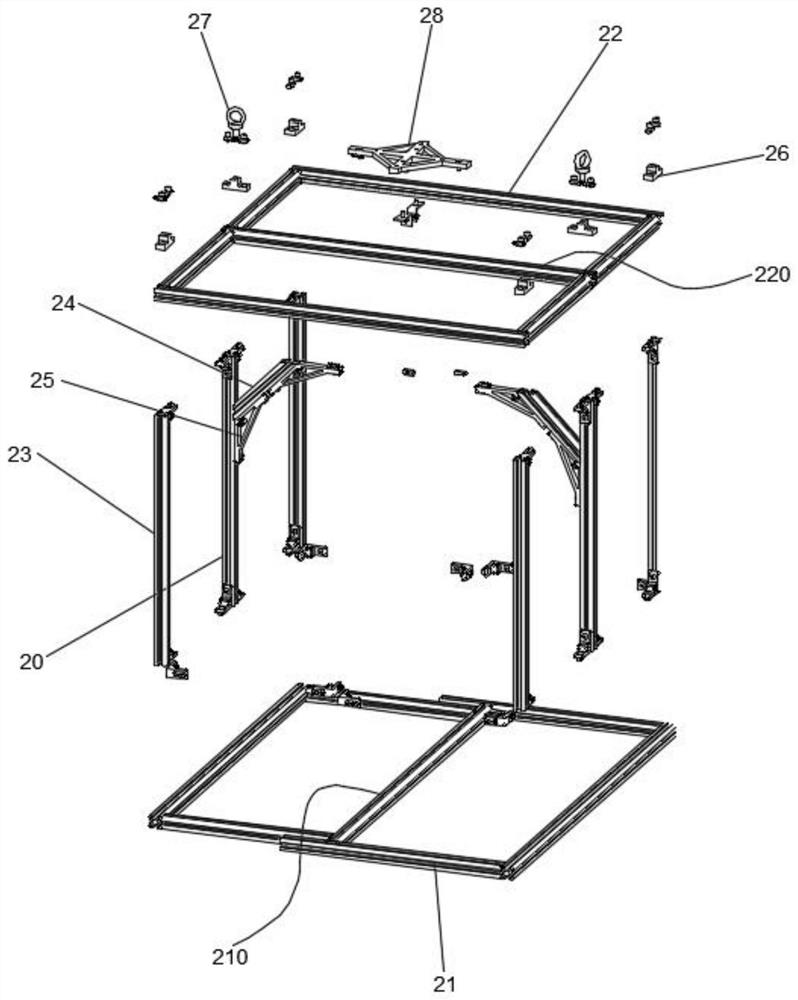

[0062] Further, as image 3 As shown, in the present application, both the profile bottom frame 21 and the profile top frame 22 can be in the shape of a Japanese font; as far as the composition of the profile to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com