Preparation method and application of antimony-doped copper/cuprous oxide electro-catalytic material

An electrocatalytic material, cuprous oxide technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of cumbersome steps, insufficient research on new high-efficiency copper and its oxide composite materials, long cycle, etc., and achieve rich synthesis and preparation. Technology, the effect of broadening application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

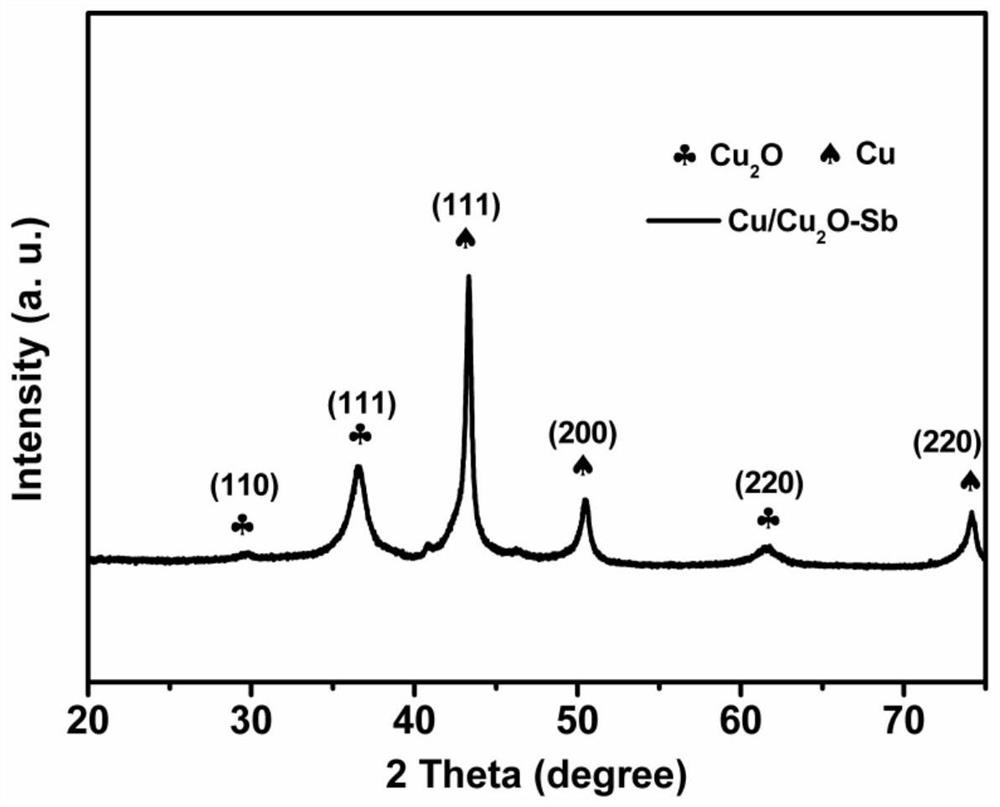

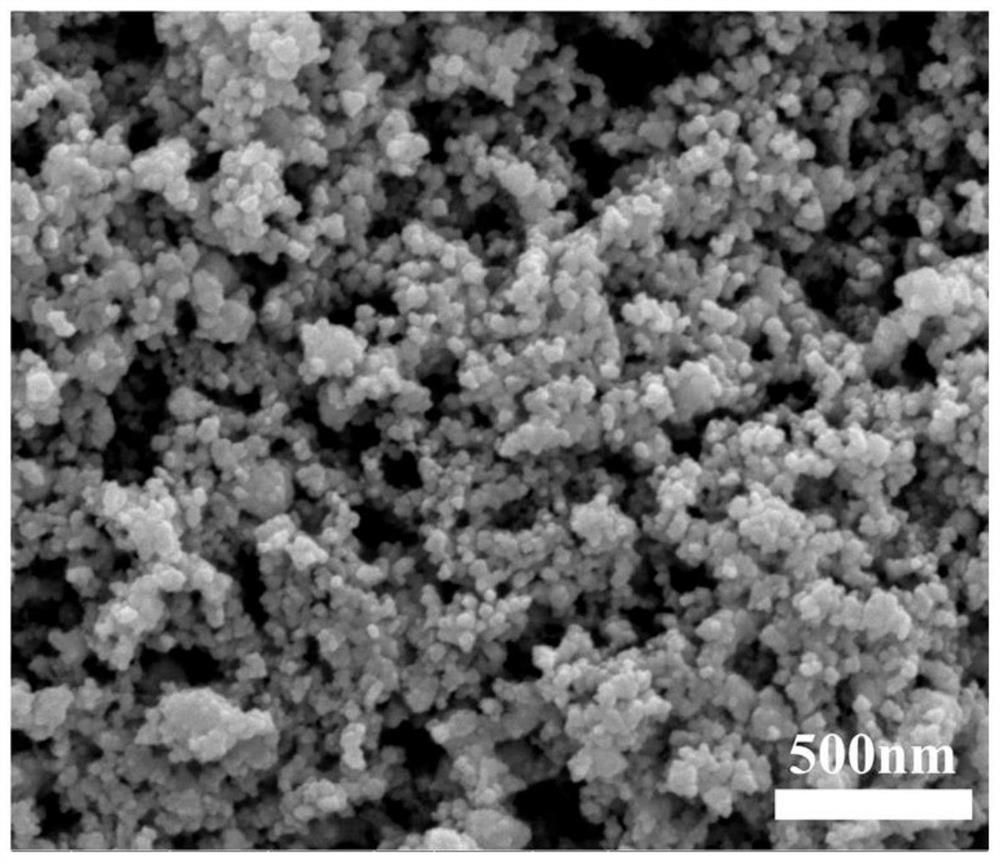

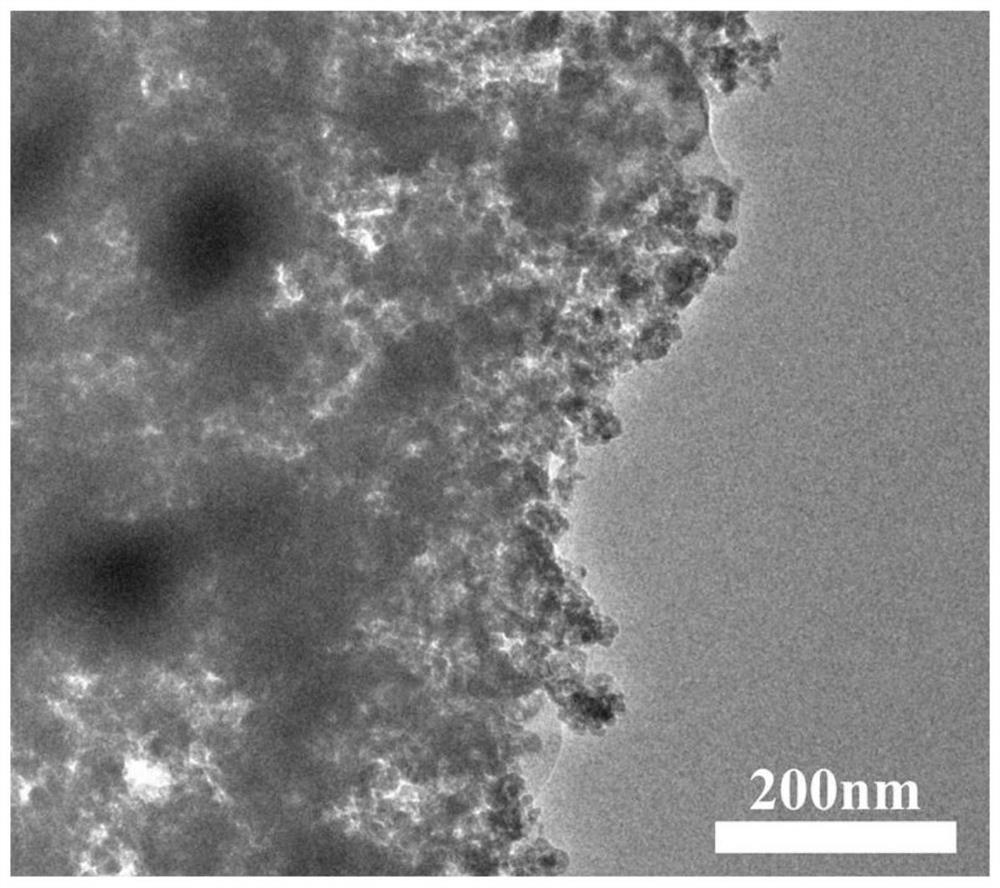

[0036] Preparation of antimony-doped copper / cuprous oxide nanoparticle composites

[0037] (1) Dissolve 10 mmol of anhydrous copper chloride powder in 100 mL of dilute hydrochloric acid solution (98 mL of deionized water, 2 mL of hydrochloric acid) to form solution A, and dissolve 2.5 mmol of antimony potassium tartrate powder in 100 mL of deionized water to form solution B.

[0038] (2) Dissolve 0.1 mol of sodium borohydride powder in 60 mL of deionized water at low temperature to form solution C. Pour solution B into solution A quickly, and stir at 0°C for 2 h to form solution D. Continue to keep 0°C constant, under vigorous stirring, solution C was dissolved in 1mLmin -1 Injected into solution C at the rate of 1, aged at this temperature for 9 hours, washed 3 times with absolute ethanol, deionized water, and acetone, and dried in vacuum at 60°C for 8 hours to obtain a typical antimony-doped copper / cuprous oxide Nanoparticle loose packing composites (Cu / Cu 2 O-Sb).

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com